Agricen’s Scott Lay recently sat with Dennis Michelsen of WITY Radio to discuss using TERRAMAR to keep corn and soybean crops on track and help protect them against yield loss.

Agricen’s Scott Lay recently sat with Dennis Michelsen of WITY Radio to discuss using TERRAMAR to keep corn and soybean crops on track and help protect them against yield loss.

Dennis - WITY Radio: One thing that we can count on is that we're going to have some very stressful days with our crops. It doesn't matter whether you're talking corn or soybeans, weather events put a lot of stress on the plants.

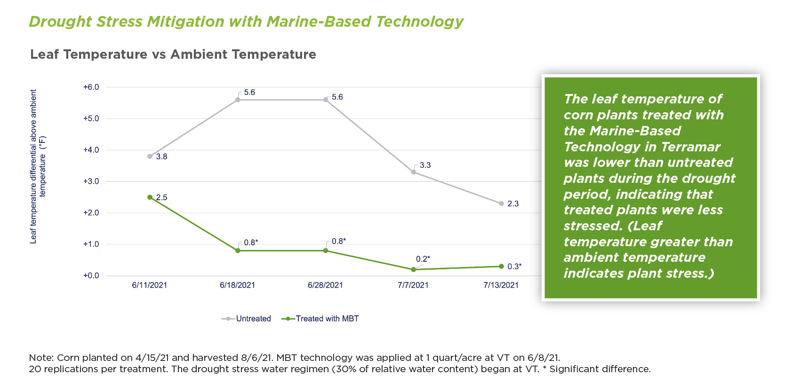

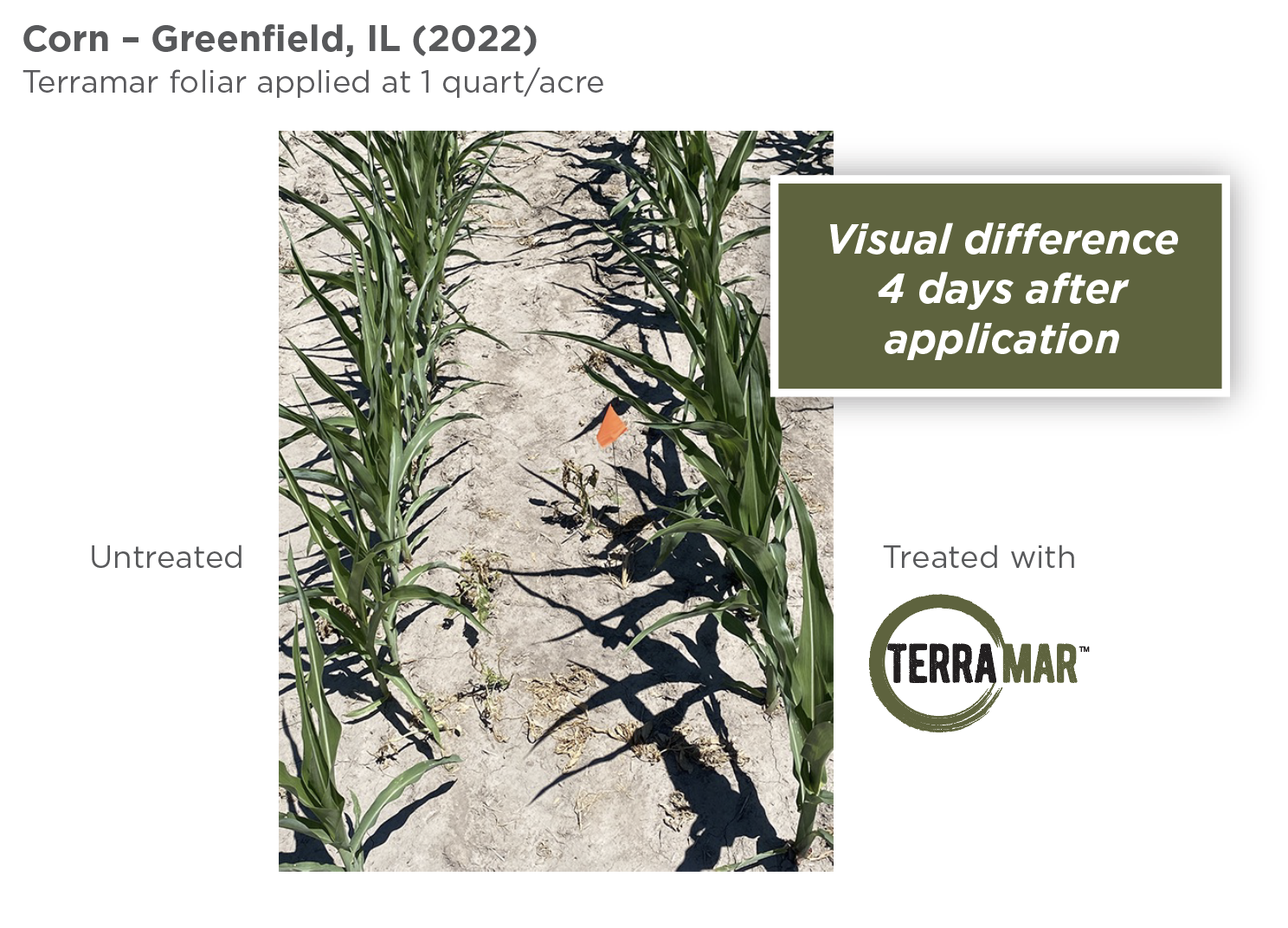

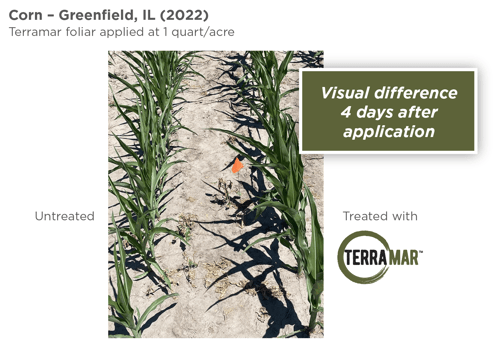

Scott - Agricen: As farmers look at their fields, regardless of zip code, any extended period of cooler temperatures like the northern half of the United States experienced this past May translates into slower developing crops, more stagnant growth and stresses that could impede the yield potential that those corn and soybean fields have. While we cannot change the weather, we can choose practices to help minimize its impact and deliver a more consistent result from year to year. That's a lot of the story behind what TERRAMAR delivers for crops.

Dennis - WITY Radio: Tell us a little bit about what TERRAMAR does for row crops.

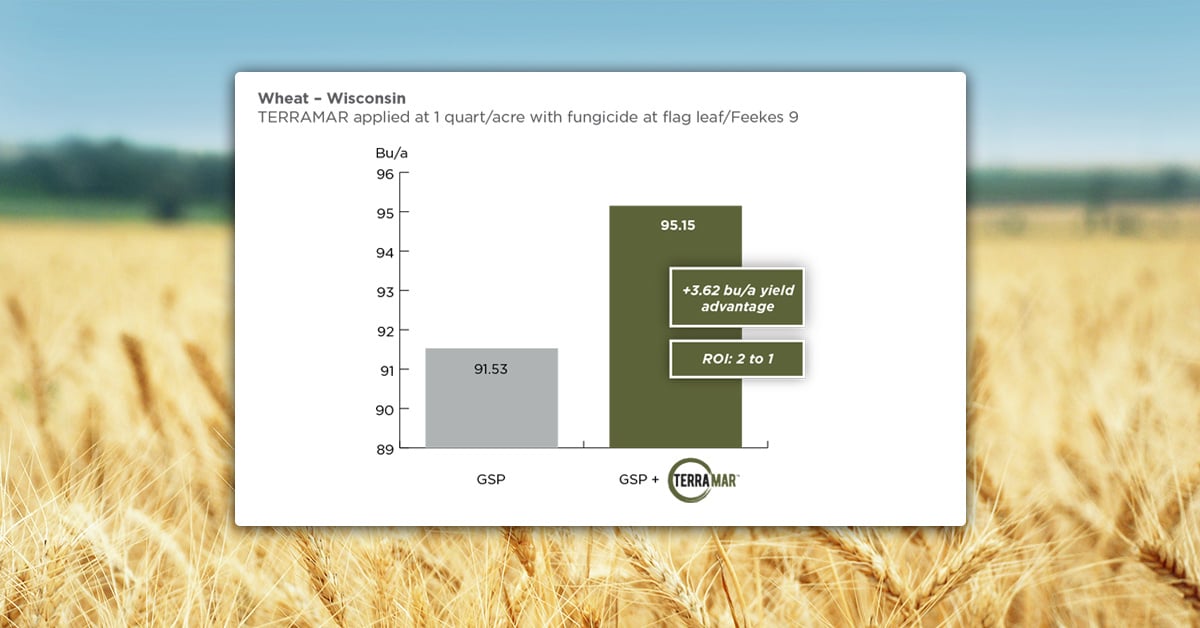

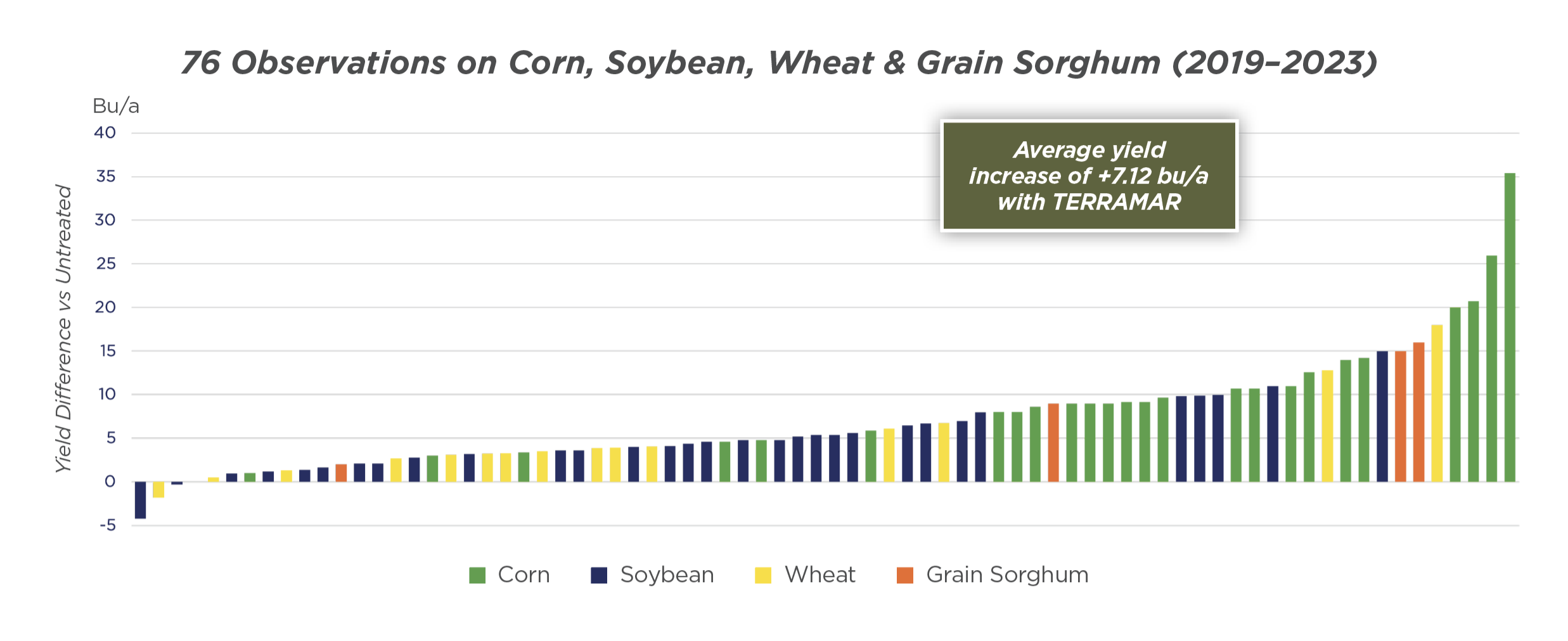

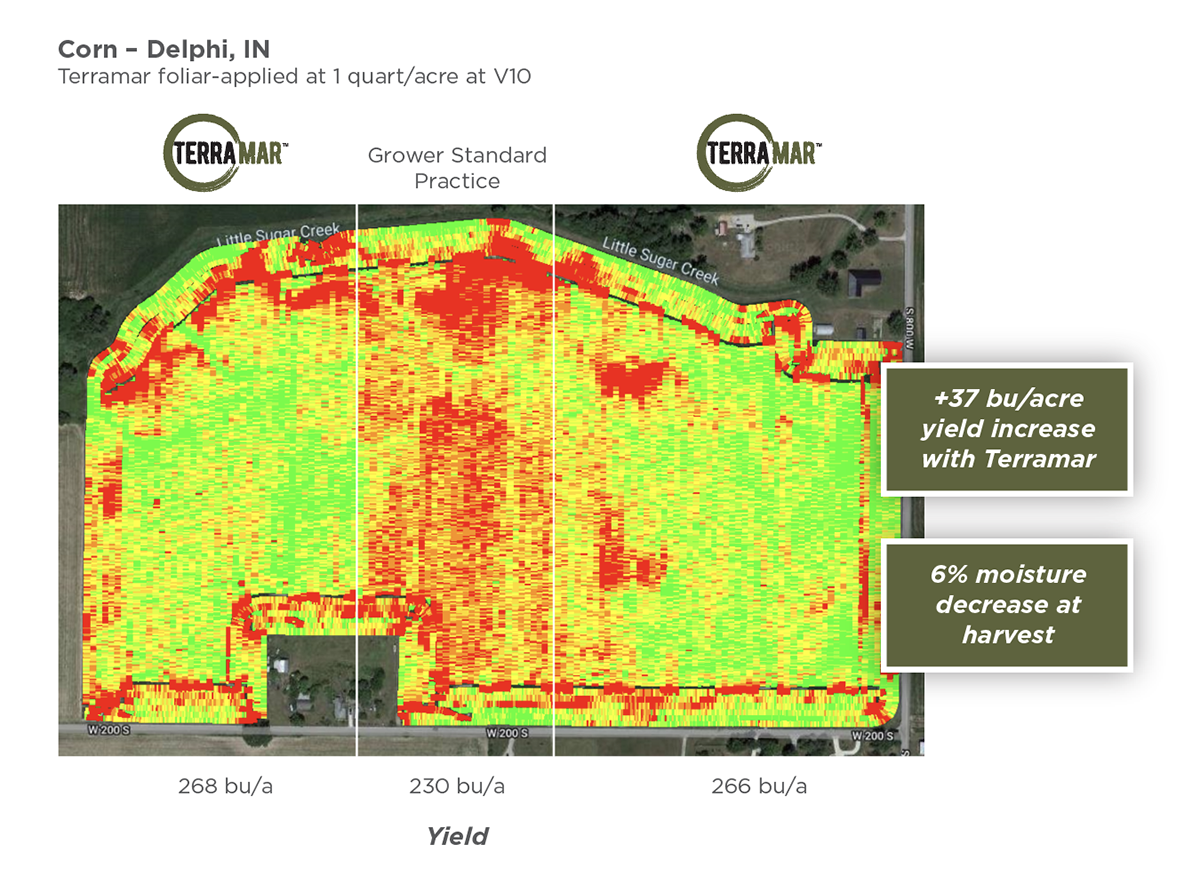

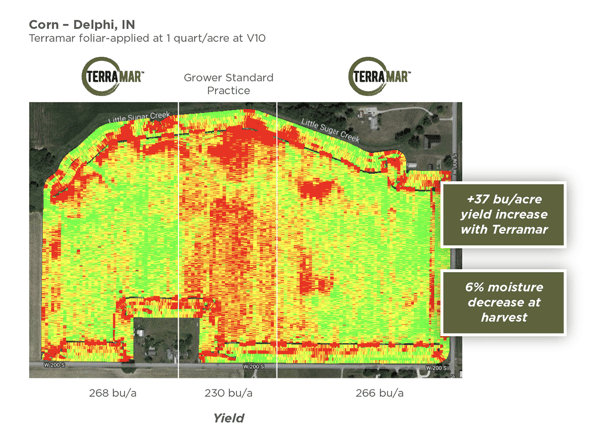

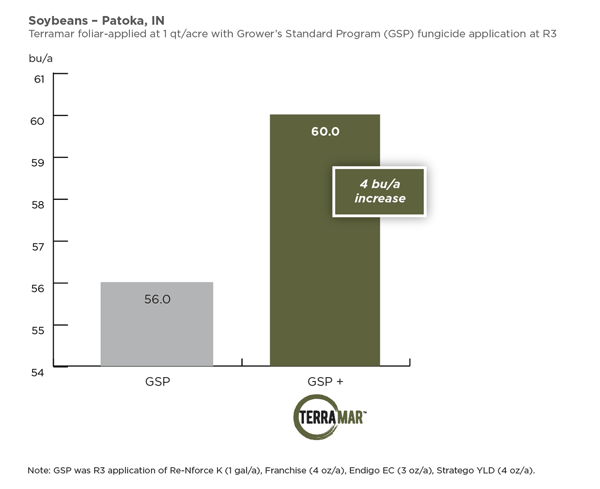

Scott - Agricen: This will be the third year we've had TERRAMAR in row crops, and we’ve been getting a lot of positive yield responses and consistency from it.

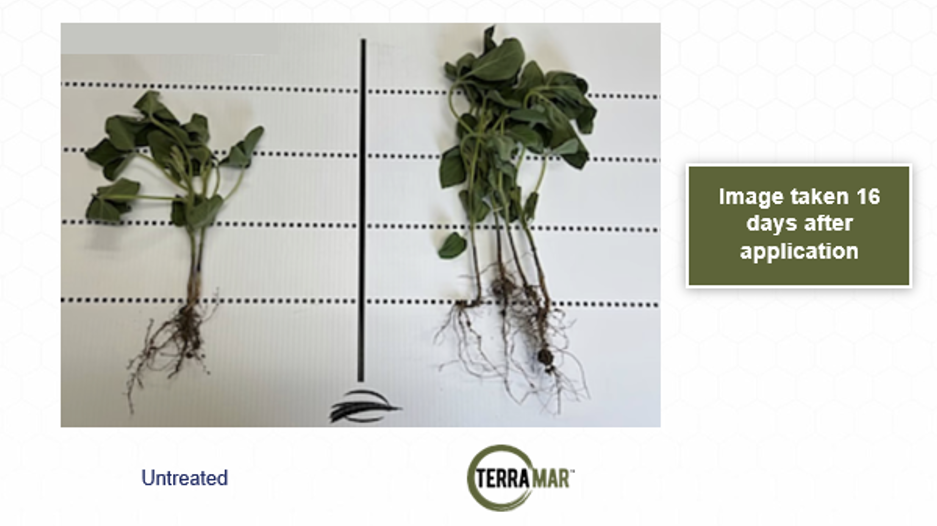

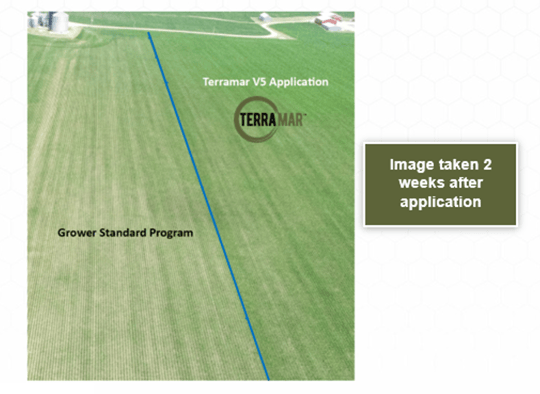

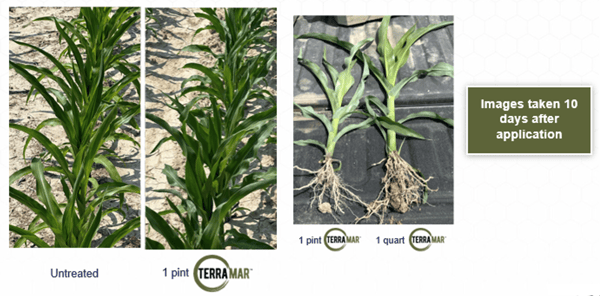

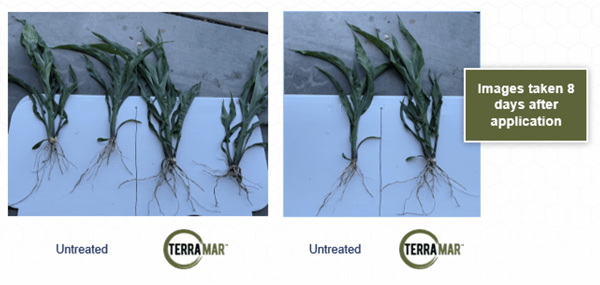

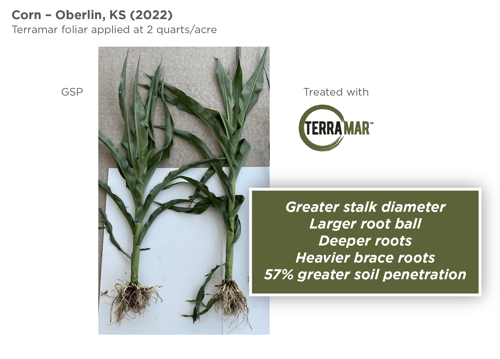

What TERRAMAR delivers boils down to two things. First, it helps minimize the impact of weather stresses like cold or heat stress. It does this by helping the plant increase photosynthesis and water transpiration to make that plant more resilient. The second part to TERRAMAR is the carbon-based component that provides fuel for the plant to allow it to uptake more nutrients. This also translates to increased sucrose levels at reproductive stages. Sucrose is a fuel source or reservoir to supply starches and sugars to the forming grain, and that's what ultimately leads to a yield advantage.

Dennis - WITY Radio: With the cold temperatures we had in May, are we going to be looking at root growth that wasn't as vigorous as usual?

Scott - Agricen: That's oftentimes the case. And again, we can't control the weather, but if we have the ability to get that plant back on track and get it performing more normally from a physiological point of view, we have a better chance of preserving yield potential and delivering a positive yield result when combines roll through the fields this fall.

Dennis - WITY Radio: How and when do you apply TERRAMAR?

Scott - Agricen: You can apply TERRAMAR anytime after the crop is emerged. At this time of year, it's really applied in concert with post-emerge foliar herbicides. As we progress later into the growing season through the reproductive stages in corn and soybeans, it can be applied with fungicides. It simply aligns with the practices that growers are already utilizing to maximize yield.

Dennis - WITY Radio: You’ve done many different test plots in various crops, and have seen repeatable results with TERRAMAR.

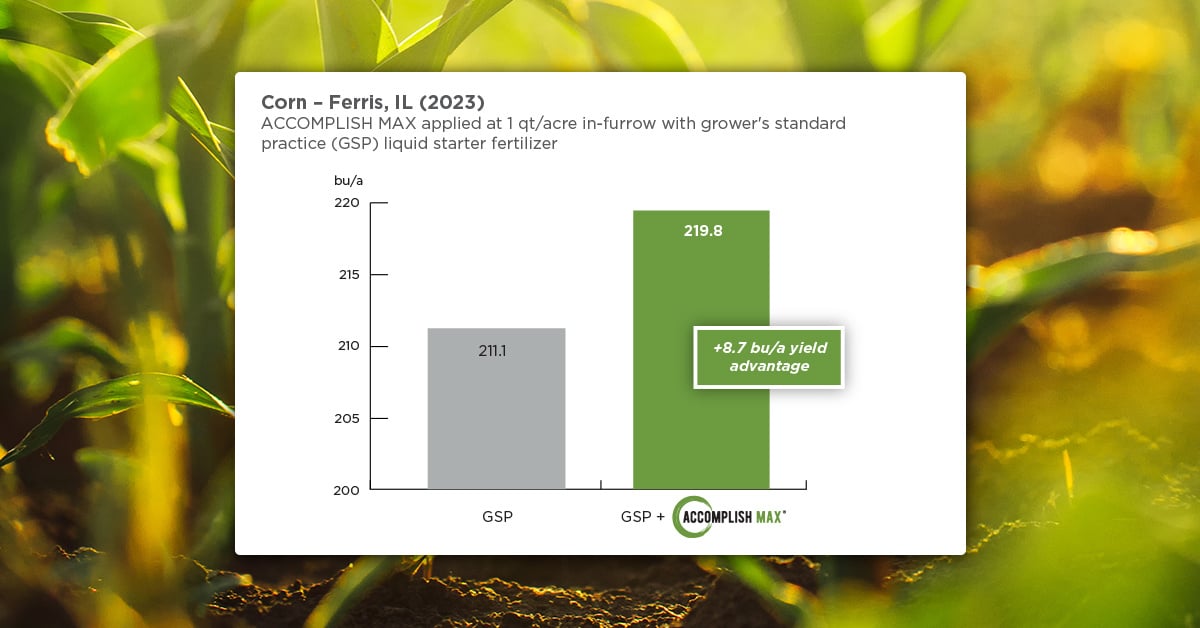

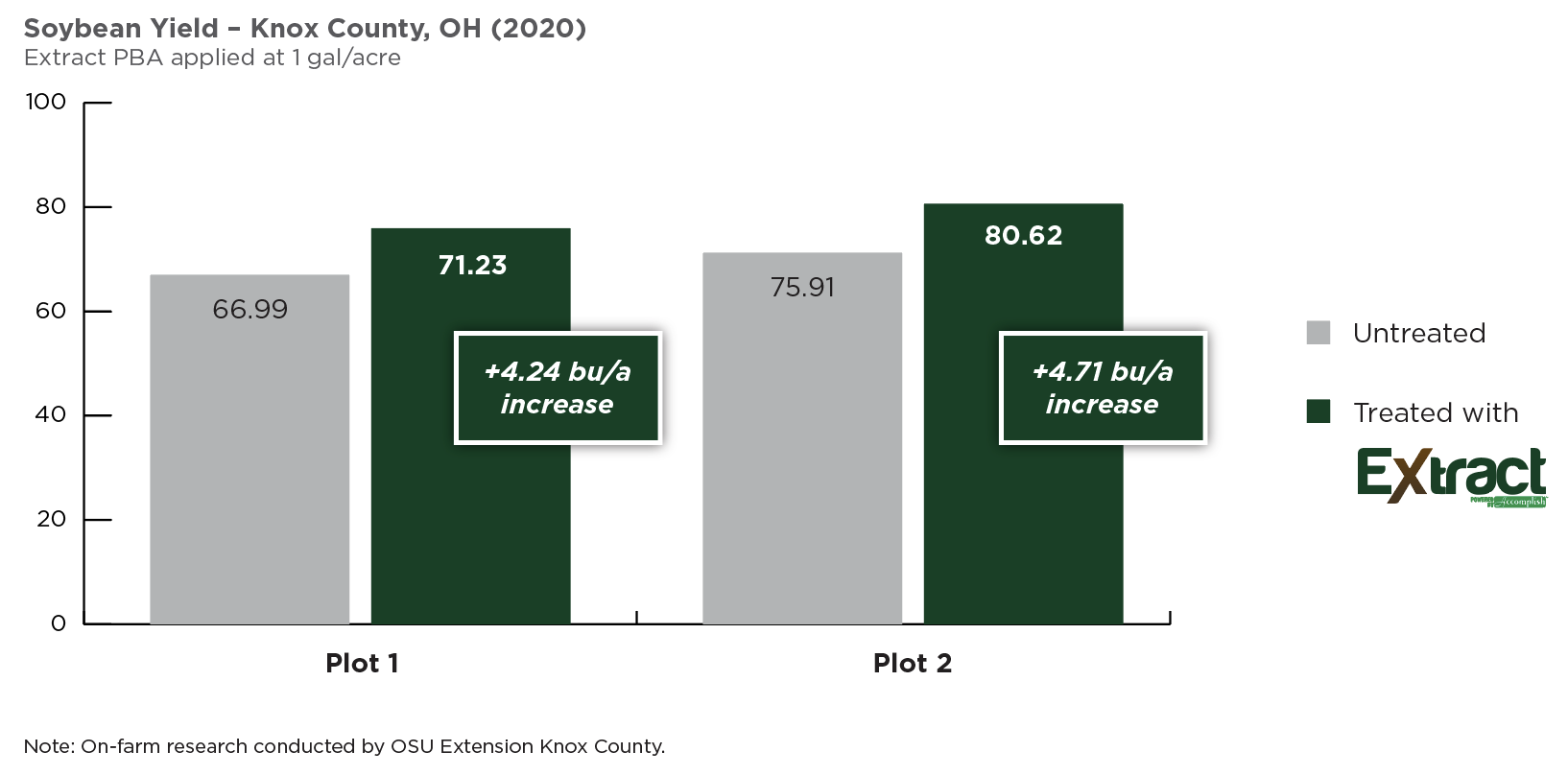

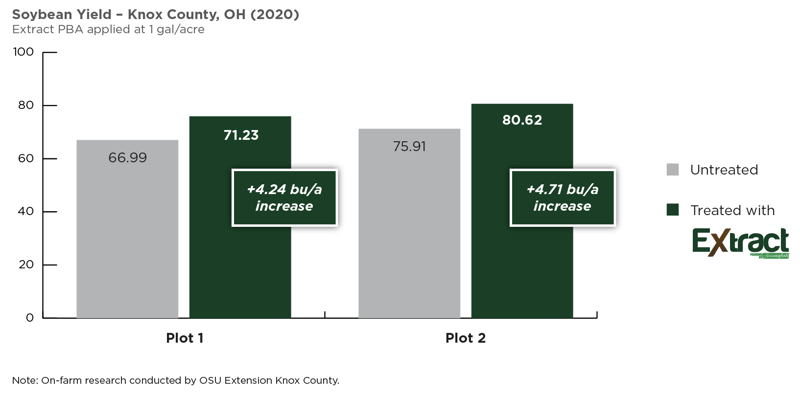

Scott - Agricen: If you're going to employ a new technology, it has to provide a consistent return on investment, particularly in the face of the commodity prices we have today. In nearly 200 yield observations, we’ve seen a positive net return on investment 85% of the time, meaning the yield return was greater than the cost of the product. On average, we see about a +4.7-bushel yield advantage in soybeans and nearly a +9-bushel yield advantage in corn. Again, that’s a positive win rate 85% of the time, meaning positive ROI. That's something you can take to the bank.

Dennis - WITY Radio: Even when it's just breaking even, this is an insurance policy to make sure that you're not losing more yield.

Scott - Agricen: It is. And again, the day you plant the crop is the greatest potential for yield that exists. The name of the game from there on after is simply preserving the yield potential that is there. If you can ensure more nutrients flowing into that plant, if you can take a bite out of the heat stress that presents itself through June and July, you've got a better chance of maintaining yield potential. As we’ve seen in hundreds of instances, that translates to a very consistent return on investment, which gives folks confidence in applying TERRAMAR.

TERRAMAR is available from Nutrien Ag Solutions.

This interview was edited for length and clarity. You can listen to the interview below or on Agricen's YouTube channel.

![[Interview] Keeping Crops on Track to Preserve Yield Potential](https://blog.agricen.com/hubfs/Interview-crop-yield-potential.jpg)

This spring, many growing areas of the United States are coming off an extended period of cooler-than-normal temperatures.

This spring, many growing areas of the United States are coming off an extended period of cooler-than-normal temperatures.

![[Watch] Preserving Yield Potential with Proactive Foliar Applications](https://blog.agricen.com/hubfs/05-25-Foliar-webinar-1200x628-watch.jpg)

![[Interview] A New Advancement in Sustainable Nitrogen Management](https://blog.agricen.com/hubfs/Interview-nitrogen-mgmt.jpg)

As growers prepare for the upcoming cropping season, uncertainties surrounding commodity prices and fertilizer, seed and crop protection inputs will heavily influence the decision-making processes before planters roll. One thing, however, is always certain: Growers want to maximize production from every acre.

As growers prepare for the upcoming cropping season, uncertainties surrounding commodity prices and fertilizer, seed and crop protection inputs will heavily influence the decision-making processes before planters roll. One thing, however, is always certain: Growers want to maximize production from every acre.

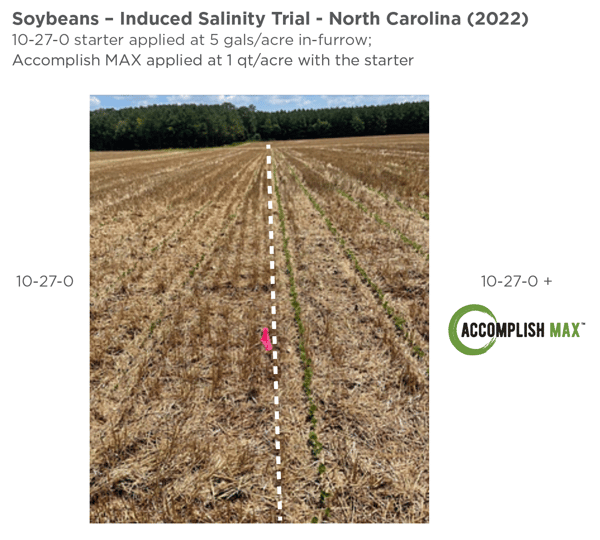

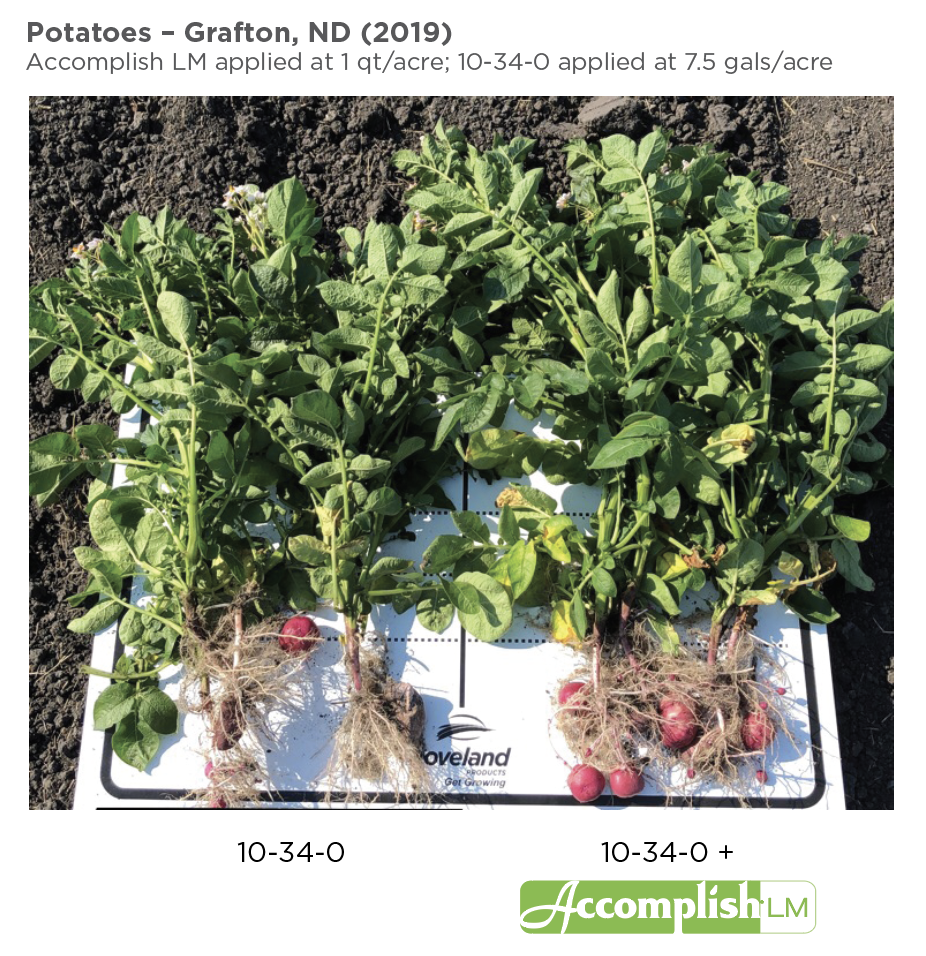

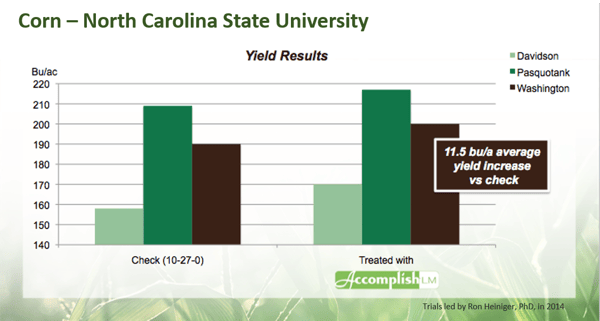

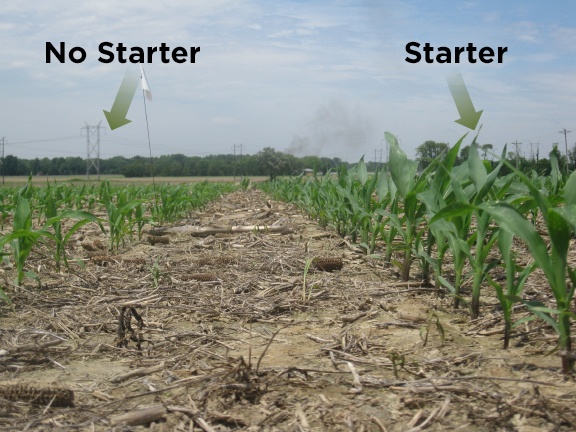

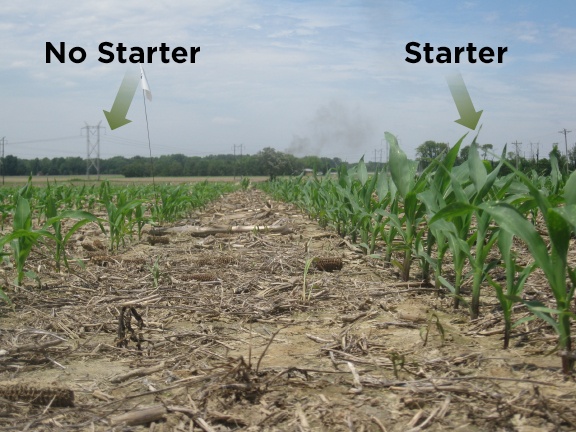

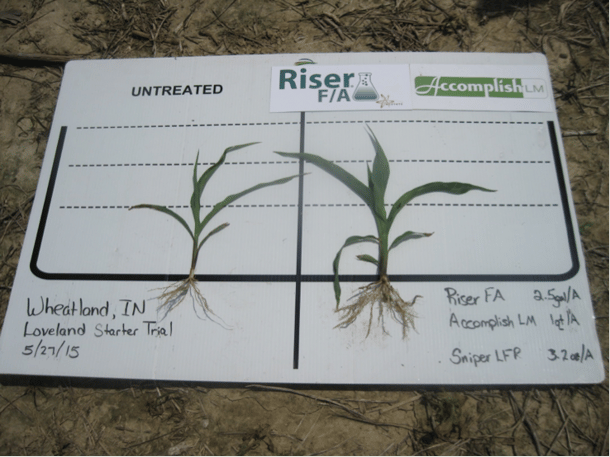

Why use a liquid starter fertilizer, and how can you make sure your applied nutrients don’t get tied up in the soil chemistry? Here you'll find the answers to these and other common questions about liquid starters.

Why use a liquid starter fertilizer, and how can you make sure your applied nutrients don’t get tied up in the soil chemistry? Here you'll find the answers to these and other common questions about liquid starters.

![[Interview] Every Dollar Counts on the Farm](https://blog.agricen.com/hubfs/Interview-every-dollar-counts.jpg)

Agricen’s Scott Lay sat with Dennis Michelsen of WITY Radio to discuss where

Agricen’s Scott Lay sat with Dennis Michelsen of WITY Radio to discuss where ![[Interview] Protecting Existing Crop Yield Potential from Heat Stress](https://blog.agricen.com/hubfs/Interview-heat-stress.jpg)

As we progress through the reproductive stage of the growing season, many growers have reason for optimism in terms of yield. But, even for those who are having a good year so far, stress from excess heat can have a negative impact on the crop. Agricen’s Scott Lay sat with Dennis Michelsen of WITY Radio to discuss how

As we progress through the reproductive stage of the growing season, many growers have reason for optimism in terms of yield. But, even for those who are having a good year so far, stress from excess heat can have a negative impact on the crop. Agricen’s Scott Lay sat with Dennis Michelsen of WITY Radio to discuss how

![[Corn Trial] Lower Canopy Temperatures & Greater Nutrient Uptake with TERRAMAR](https://blog.agricen.com/hubfs/Terramar-tissue-samples-1200px.jpg)

![[Interview] Addressing Weather-Induced Crop Stress](https://blog.agricen.com/hubfs/Interview-weather-stress.jpg)

As growers finish putting this year’s crop in the ground, Agricen’s Scott Lay spoke with WITY Radio’s Dennis Michelsen about

As growers finish putting this year’s crop in the ground, Agricen’s Scott Lay spoke with WITY Radio’s Dennis Michelsen about

![[On-Demand Ag Webinar] Stand Up to Stress for Higher Yield & ROI](https://blog.agricen.com/hubfs/CropLife-webinar-1200px-1.jpg)

![[Watch] Opportunities for Enhancing Nutrient Availability with Extract](https://blog.agricen.com/hubfs/Extract-watch-now-1200px.jpg)

![[Interview] Helping Dry Fertilizer Overcome Cool Weather Challenges](https://blog.agricen.com/hubfs/AgriTalk%20podcast%201200px.jpg)

Ron Calhoun, PhD, Senior Manager for Plant Nutrition at Loveland Products, sat with AgriTalk’s Chip Flory to discuss the challenges that cool weather can bring when growers add dry nutrition to the soil during the fall.

Ron Calhoun, PhD, Senior Manager for Plant Nutrition at Loveland Products, sat with AgriTalk’s Chip Flory to discuss the challenges that cool weather can bring when growers add dry nutrition to the soil during the fall.

Jason Jaggers is a third-generation corn and soybean farmer in Wyanet, Illinois. When it comes to getting advice from his

Jason Jaggers is a third-generation corn and soybean farmer in Wyanet, Illinois. When it comes to getting advice from his

![[Interview] Put Your Chips on Titan XC This Fall](https://blog.agricen.com/hubfs/Interview-TitanXC.jpg)

Agricen's Scott Lay recently spoke with Dennis Michelsen of WITY Radio about using

Agricen's Scott Lay recently spoke with Dennis Michelsen of WITY Radio about using ![[Watch] Enhance Dry Fertilizer Efficiency to Maximize Yield & ROI](https://blog.agricen.com/hubfs/09-23-Webinar-Dry-Fertilizer-1200px-Watch-Now.jpg)

![[Interview] Taking a Bite Out of Drought & Heat Stress in Agriculture](https://blog.agricen.com/hubfs/Interview-drought-heat-stress.jpg)

Lee Lubbers, an

Lee Lubbers, an

Many agricultural areas across the United States are facing weather-related challenges, but there are still opportunities to make the most

Many agricultural areas across the United States are facing weather-related challenges, but there are still opportunities to make the most

![[On-Demand] Terramar: A New Way to Help Row Crops Stand Up to Stress](https://blog.agricen.com/hubfs/Terramar-watch-now-1200px-1.jpg)

![[Interview] Employing Sustainable Technologies to Enhance Yield](https://blog.agricen.com/hubfs/Sustainable-Technologies-1200px%20%281%29.jpg)

Agricen's Scott Lay recently spoke with Dennis Michelsen of WITY Radio about

Agricen's Scott Lay recently spoke with Dennis Michelsen of WITY Radio about

.jpg?width=600&height=314&name=NCGA_social-2022%20(1).jpg)

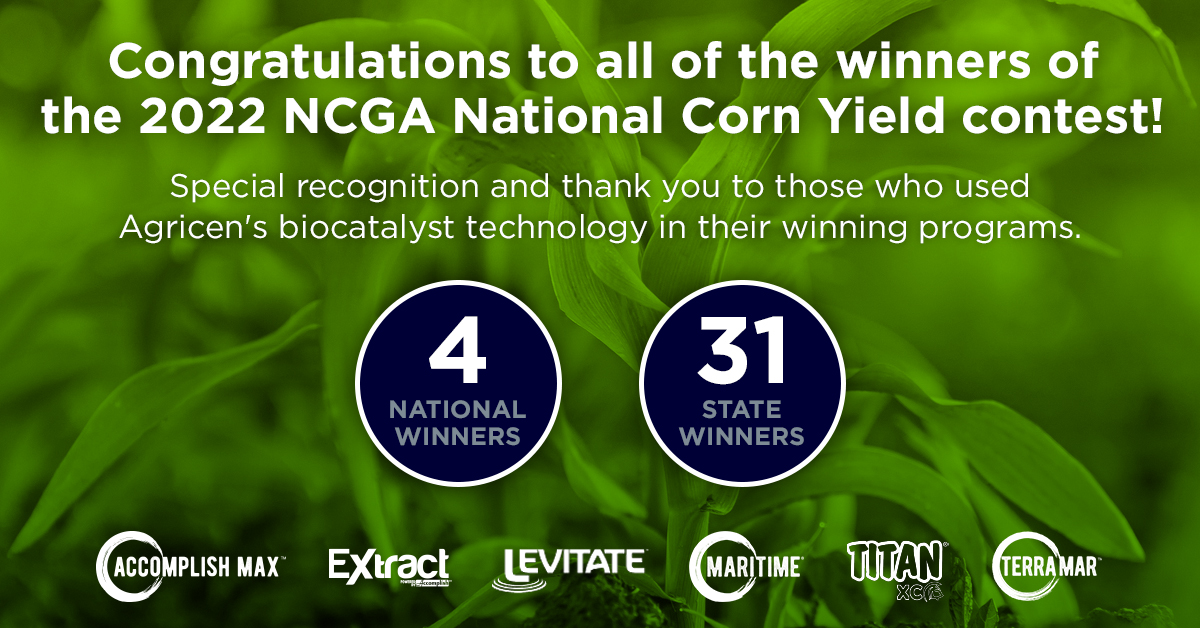

![[Trial] Impressive Yield Results with ACCOMPLISH MAX in Irrigated Corn](https://blog.agricen.com/hubfs/MAX-irrigated-corn-1200px.jpg)

![[Watch] Early Season Opportunities to Enhance Plant Nutrition & Health](https://blog.agricen.com/hubfs/Early-season-opp-watch-now.jpg)

The value of

The value of

![[Watch] How to Make Your Dry Fertilizer Work Harder & Go Farther](https://blog.agricen.com/hubfs/DryFert-WatchNow-1200px.jpg)

With fall fertilizer season approaching, Agricen’s Scott Lay spoke with WITY Radio about using

With fall fertilizer season approaching, Agricen’s Scott Lay spoke with WITY Radio about using

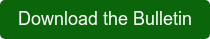

Sugar beets are a major source of the world's sugar, and the higher the sugar yield and concentration per plant, the better. In a replicated trial, researchers evaluated the ability of

Sugar beets are a major source of the world's sugar, and the higher the sugar yield and concentration per plant, the better. In a replicated trial, researchers evaluated the ability of

We are proud to announce that our farming film,

We are proud to announce that our farming film,

With planting wrapping up, Agricen’s Scott Lay sat down with

With planting wrapping up, Agricen’s Scott Lay sat down with

With the spring planting season coming, Agricen’s Scott Lay spoke with Dennis Michelsen on

With the spring planting season coming, Agricen’s Scott Lay spoke with Dennis Michelsen on

As growers start crop planning for the upcoming season, where do fertilizer enhancers fit in?

As growers start crop planning for the upcoming season, where do fertilizer enhancers fit in?

Evan Matlock, a farmer from Greenfield, Indiana, first started using

Evan Matlock, a farmer from Greenfield, Indiana, first started using

![[Watch] Minimizing Crop Stresses for Increased Yields](https://blog.agricen.com/hubfs/crop-stresses-webinar-600px_v3.jpg)

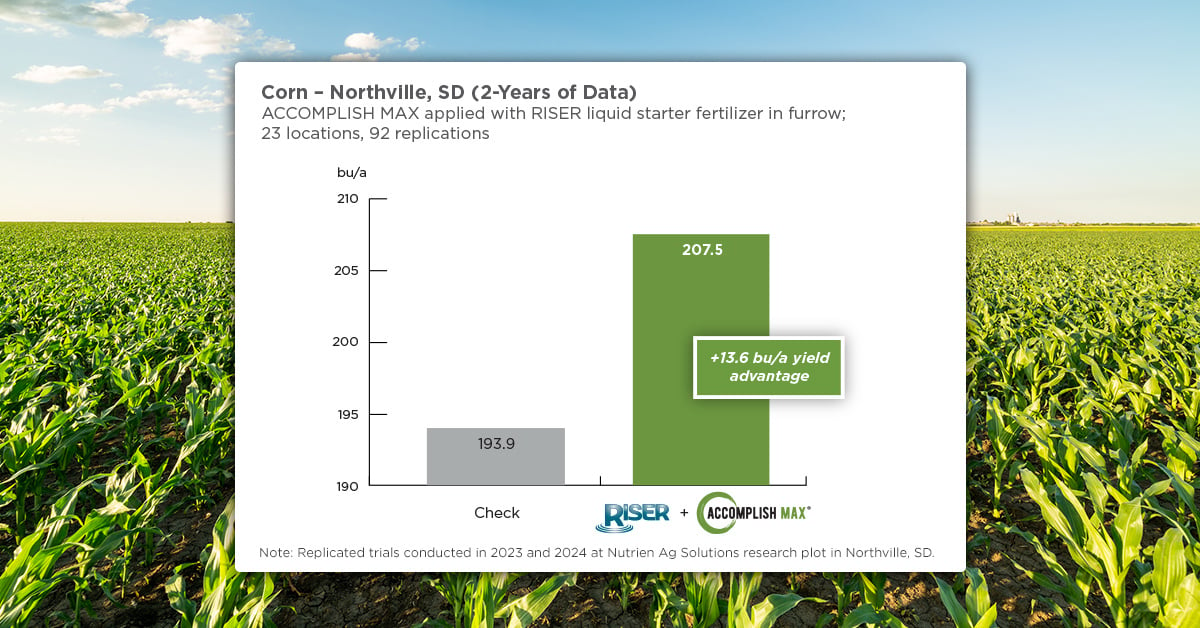

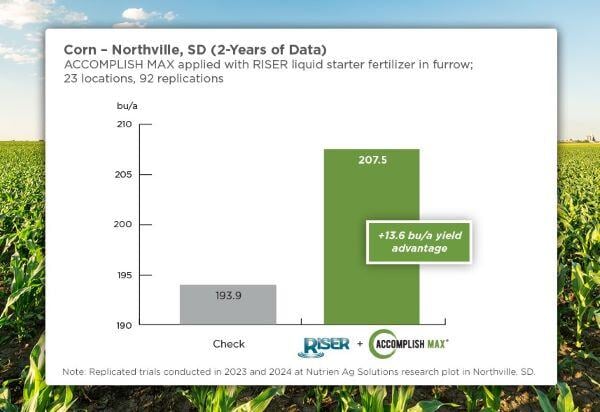

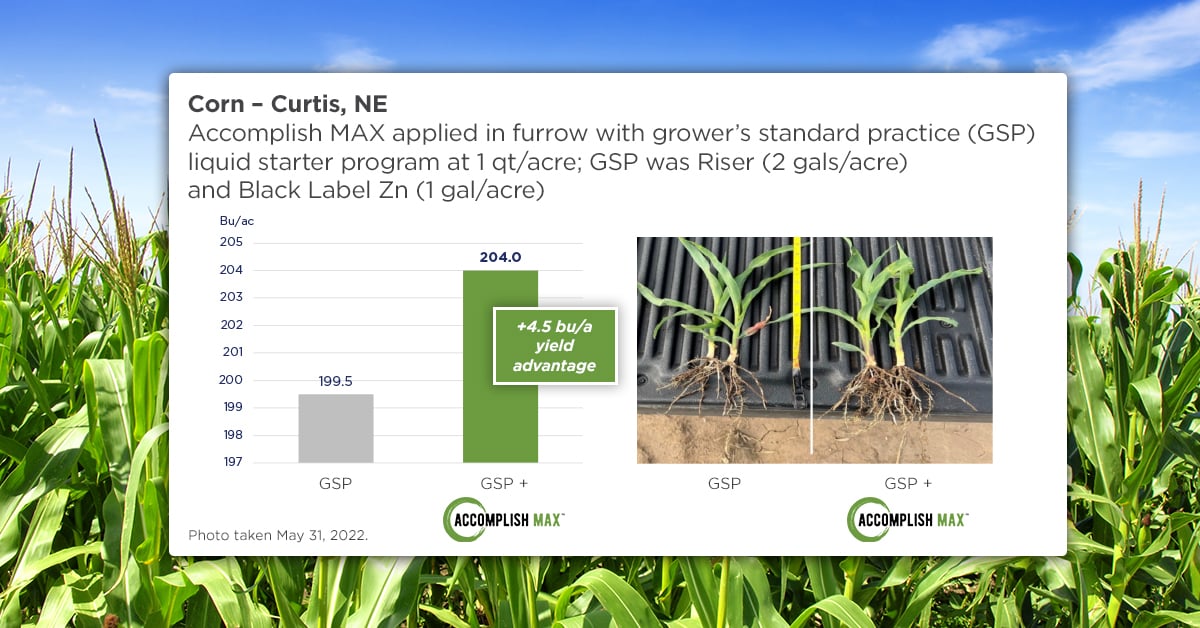

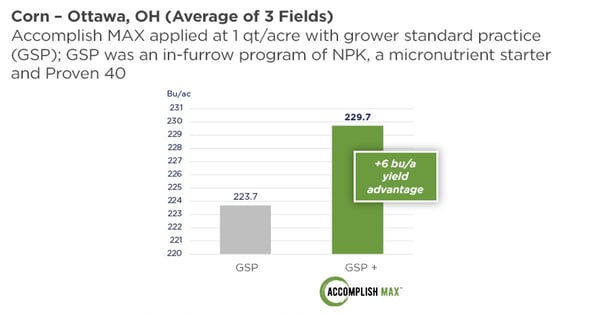

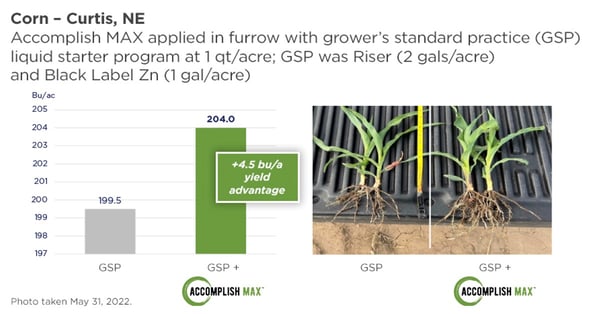

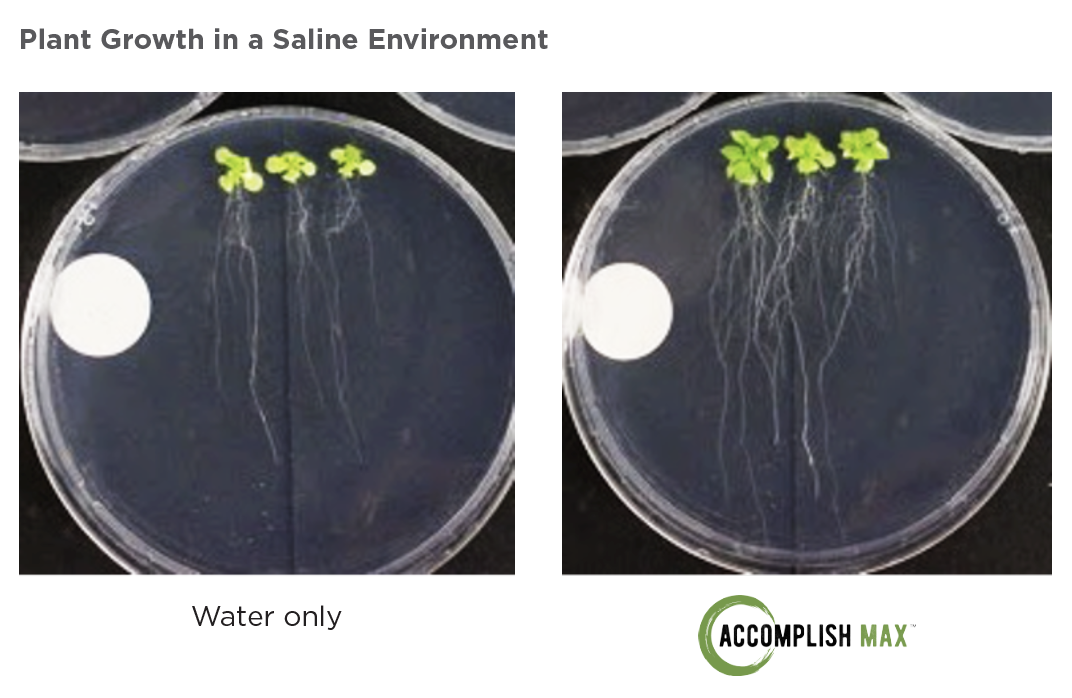

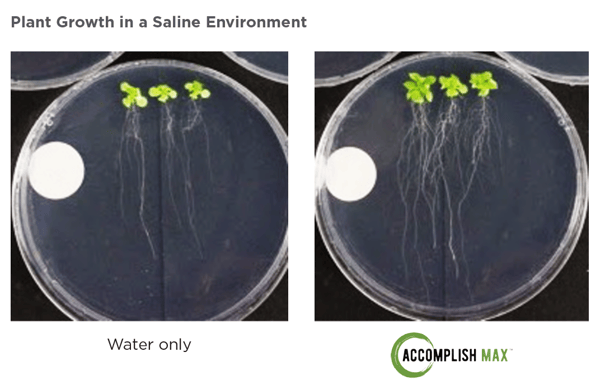

Accomplish MAX

Accomplish MAX

![[Hoosier Ag Today] Maximizing Your Dry Fertilizer Investment](https://blog.agricen.com/hubfs/Dry%20Fertilizer%20Spreader.png)

![[WITY Radio] Sometimes the Answer Is Not More Fertilizer](https://blog.agricen.com/hubfs/09-21-down-on-the-farm.jpg)

Cathy and Martin Quigley struck gold in the

Cathy and Martin Quigley struck gold in the

Does a pre-emergence application of

Does a pre-emergence application of

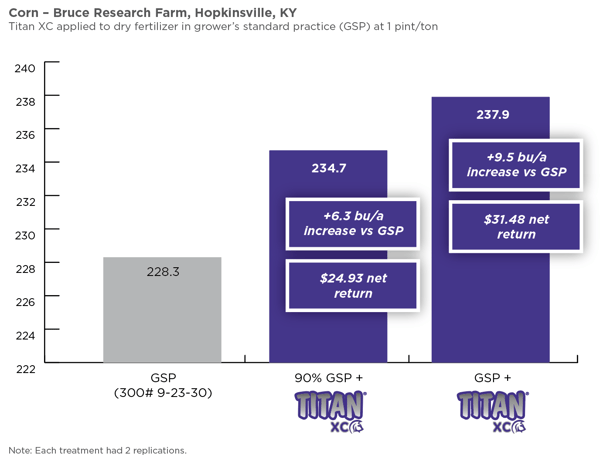

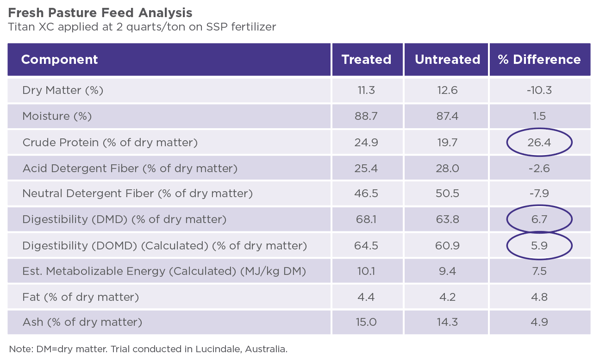

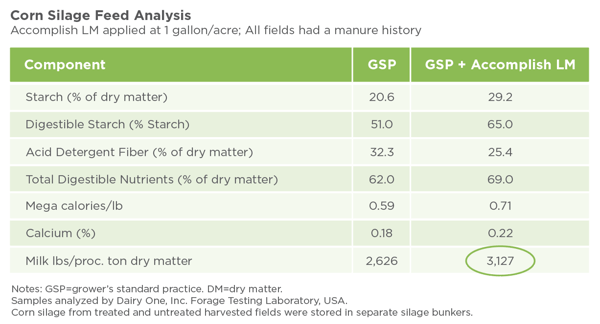

When it comes to growing forage and pasture crops as feed for a successful livestock operation, simply increasing the biomass of these crops isn't enough. Feed quality is another important consideration. In fact, it may be the most important variable in livestock and dairy production, as increased feed quality can lead to higher production of meat and milk.

When it comes to growing forage and pasture crops as feed for a successful livestock operation, simply increasing the biomass of these crops isn't enough. Feed quality is another important consideration. In fact, it may be the most important variable in livestock and dairy production, as increased feed quality can lead to higher production of meat and milk.

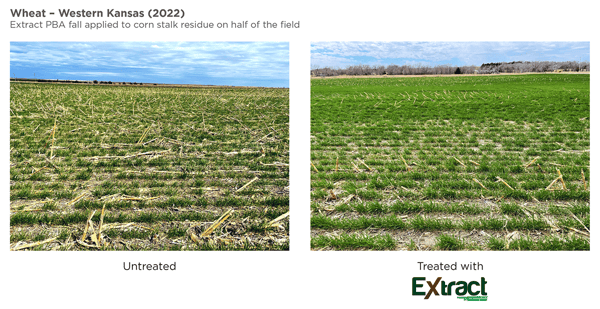

Already a busy period, harvest is also the time for growers to begin planning for next season's crop. Fall planning can be critical to having a less stressful planting season in the spring. Incorporating

Already a busy period, harvest is also the time for growers to begin planning for next season's crop. Fall planning can be critical to having a less stressful planting season in the spring. Incorporating

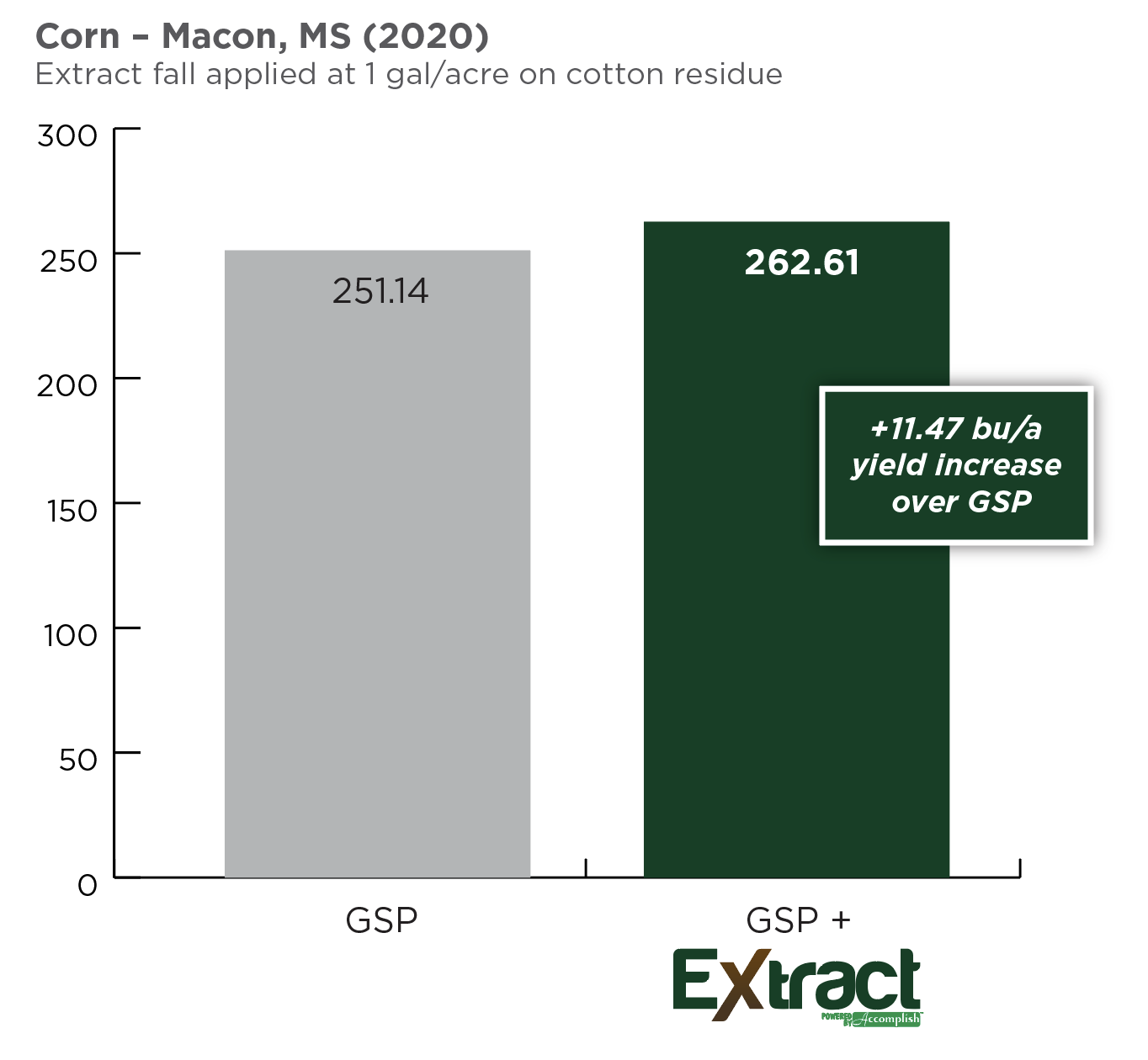

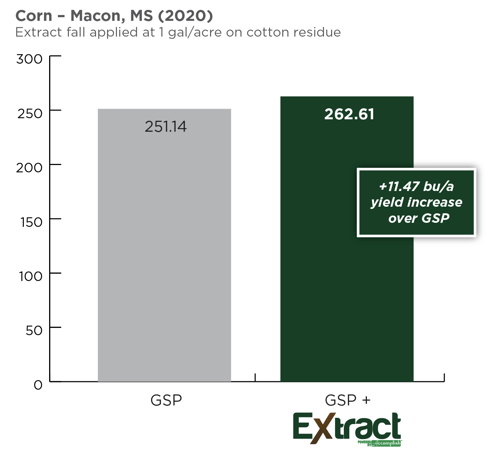

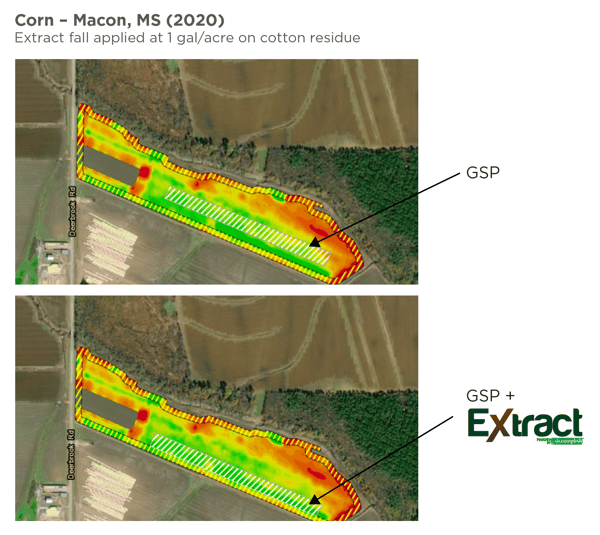

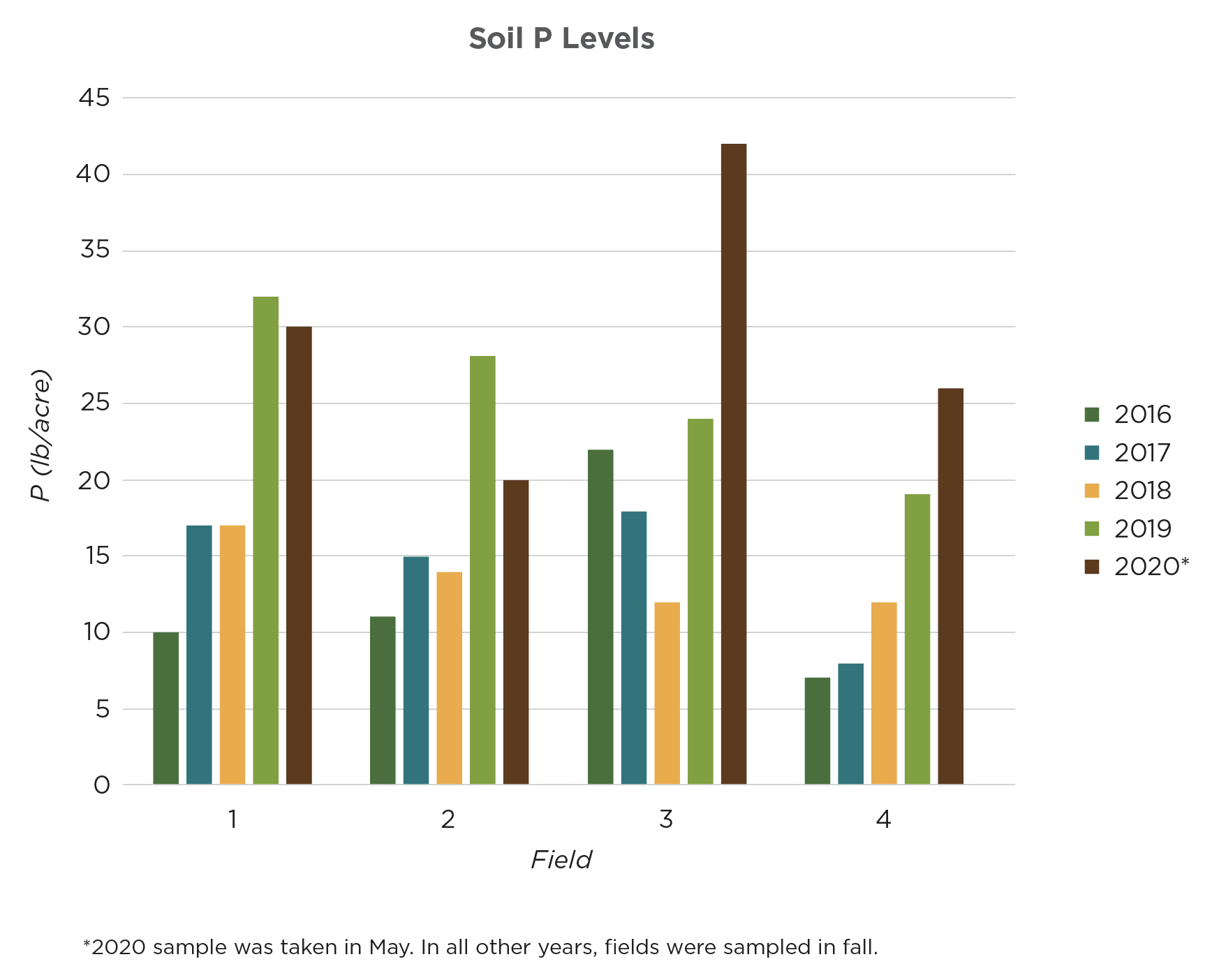

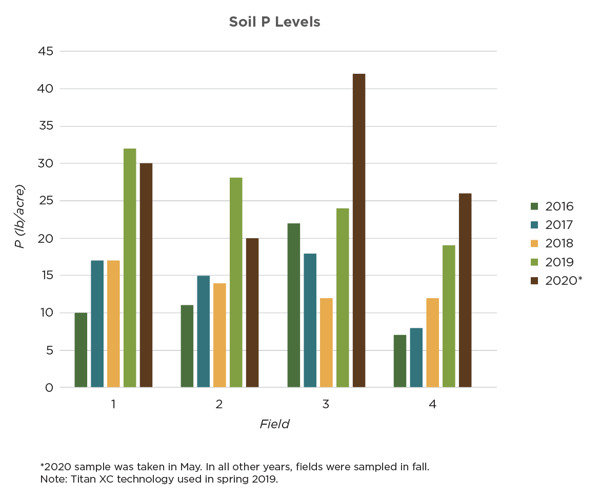

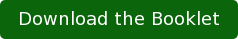

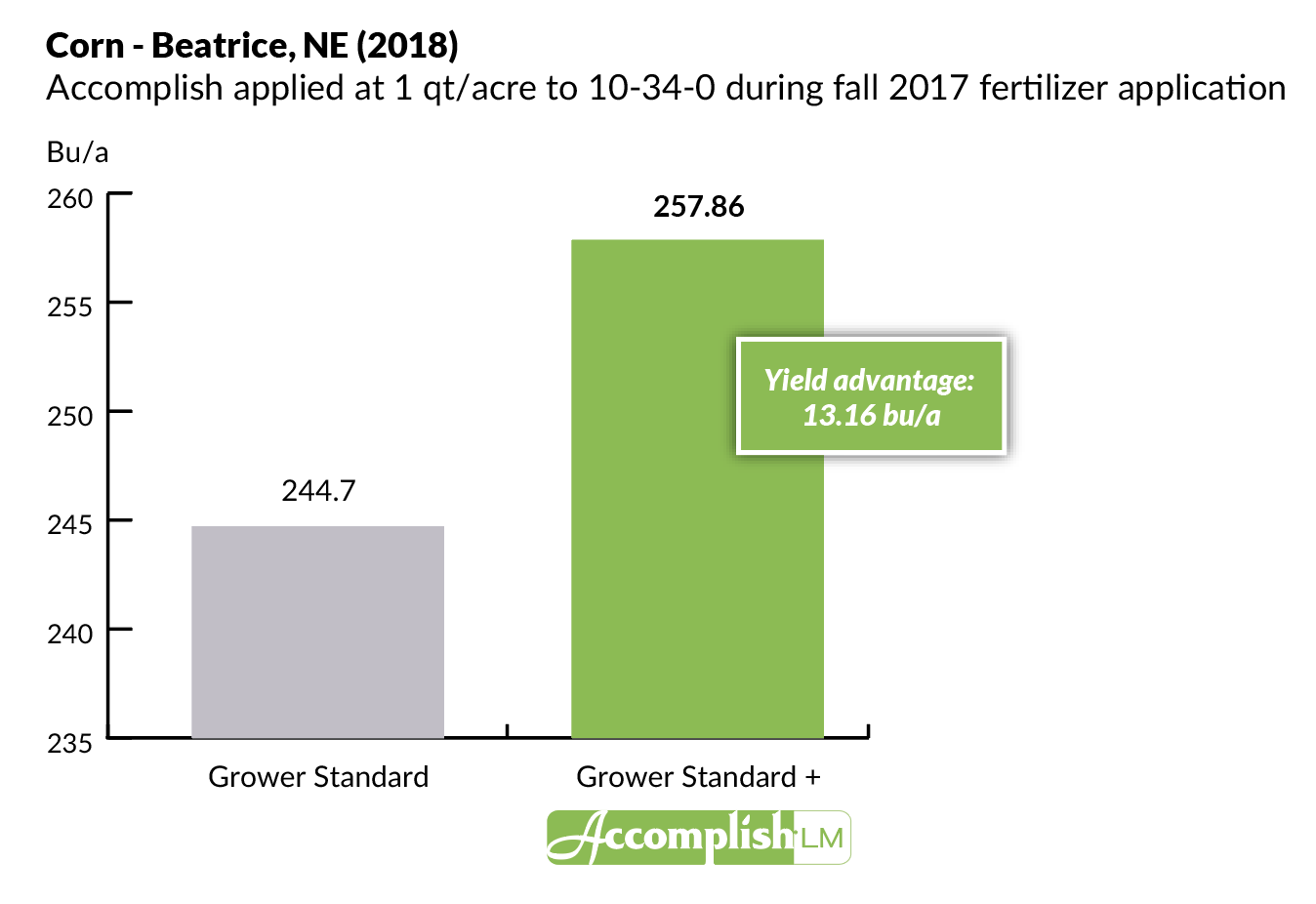

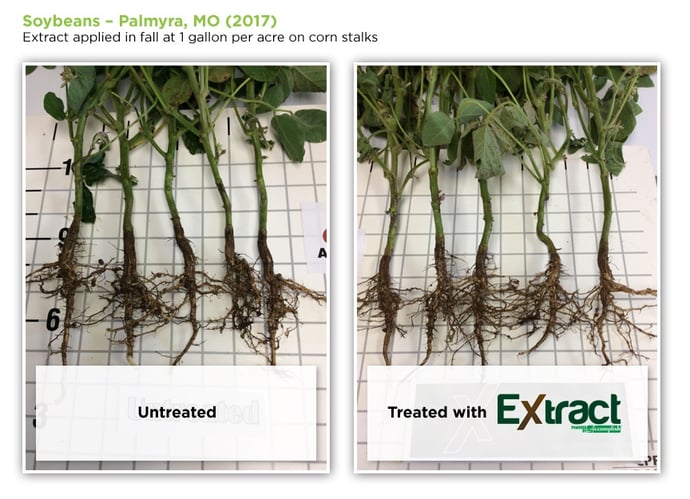

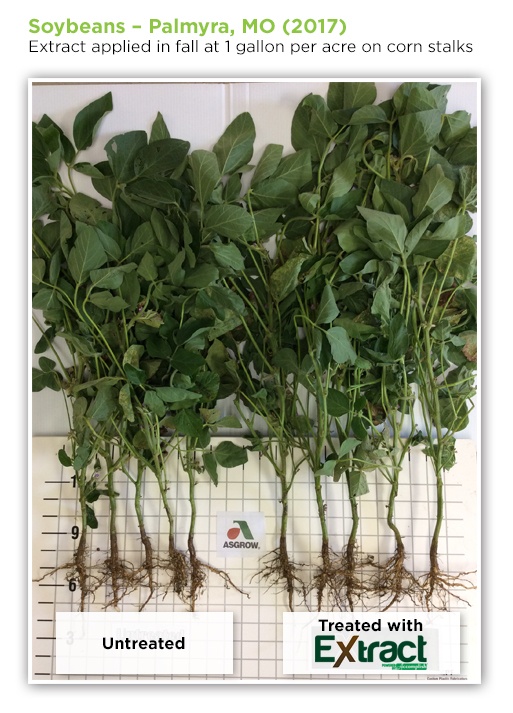

In the fall of 2017, Benjamin Rice, a crop consultant for

In the fall of 2017, Benjamin Rice, a crop consultant for

Luke Bryan makes a valid point when he sings, “rain makes corn,” but do you know what can help make even more corn?

Luke Bryan makes a valid point when he sings, “rain makes corn,” but do you know what can help make even more corn?

![[Booklet] MARITIME Innovative Kelp Science for Crops](https://blog.agricen.com/hubfs/Maritime-1200x628-02.png)

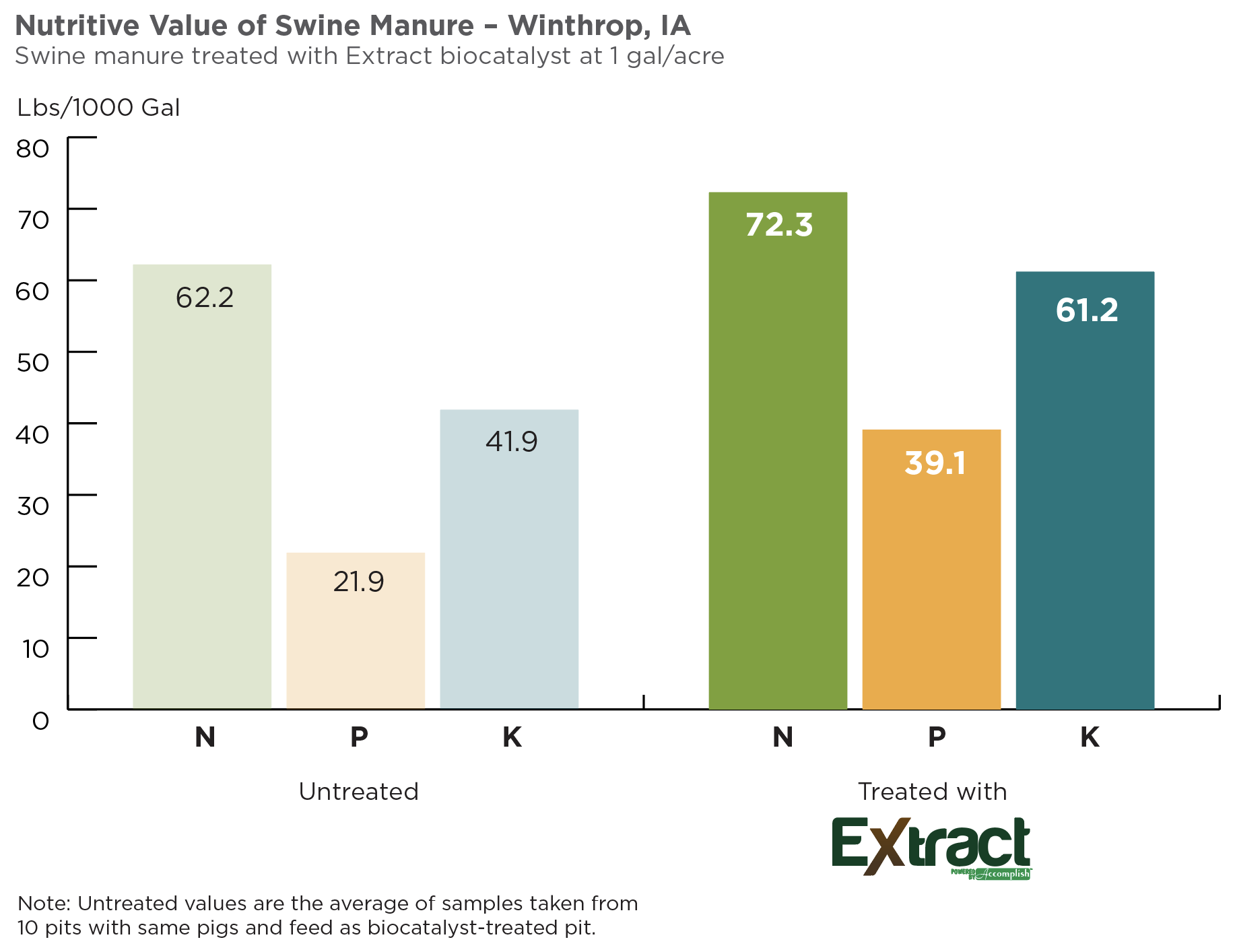

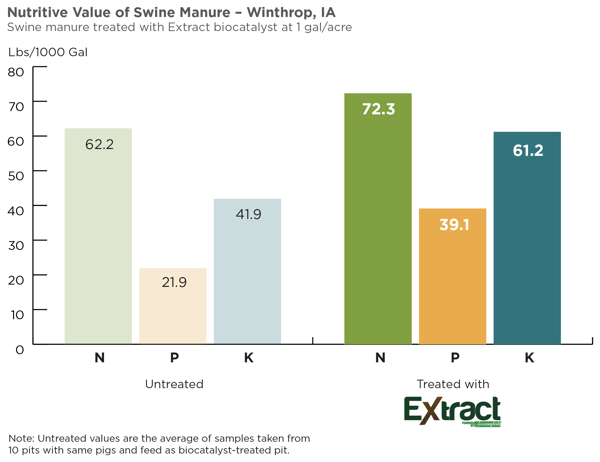

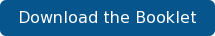

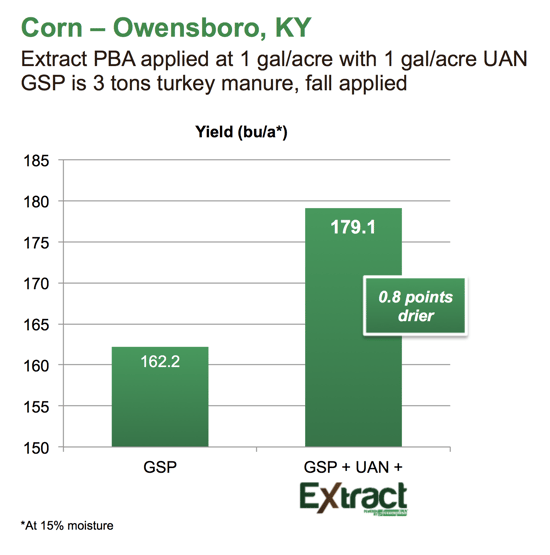

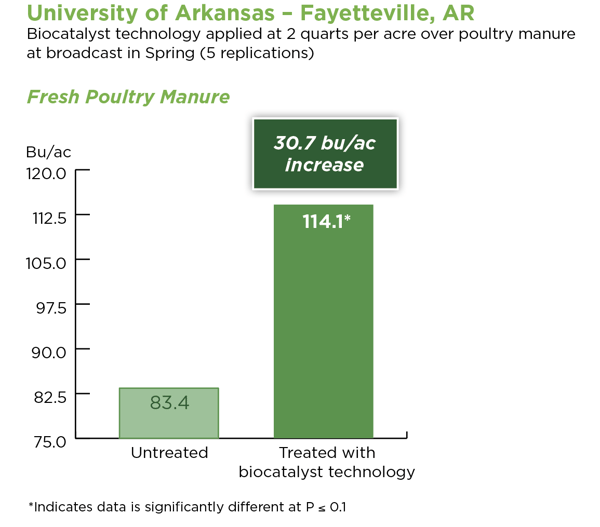

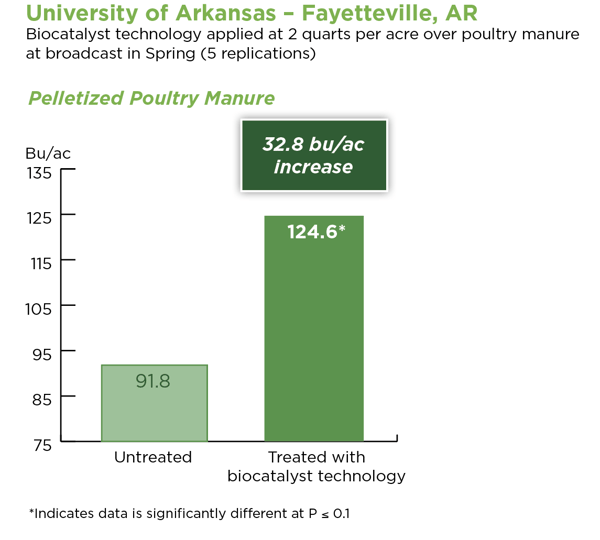

Although animal manures can be a rich source of nutrients for crops, the nutrients found in them

Although animal manures can be a rich source of nutrients for crops, the nutrients found in them

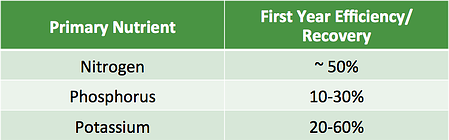

Many growers apply the “4R” framework for nutrient management—using the right fertilizer source, at the right rate, at the right time and in the right place—to more closely match

Many growers apply the “4R” framework for nutrient management—using the right fertilizer source, at the right rate, at the right time and in the right place—to more closely match

Wet conditions in the spring can create major planting challenges for growers. Flooding and excess moisture in the fields can lead to millions of acres being left unplanted. Unfortunately, this can create favorable conditions for fallow syndrome, a phosphorus deficiency in the soil that can negatively impact next season’s crop.

Wet conditions in the spring can create major planting challenges for growers. Flooding and excess moisture in the fields can lead to millions of acres being left unplanted. Unfortunately, this can create favorable conditions for fallow syndrome, a phosphorus deficiency in the soil that can negatively impact next season’s crop.

Fifth-generation farmer, Dave Kolb, of Kolb Farms near Paynesville, Minnesota, is one of 11 children who grew up working on a dairy farm with his siblings and parents. The Kolbs have been in this area since their ancestors arrived to homestead in 1861.

Fifth-generation farmer, Dave Kolb, of Kolb Farms near Paynesville, Minnesota, is one of 11 children who grew up working on a dairy farm with his siblings and parents. The Kolbs have been in this area since their ancestors arrived to homestead in 1861.

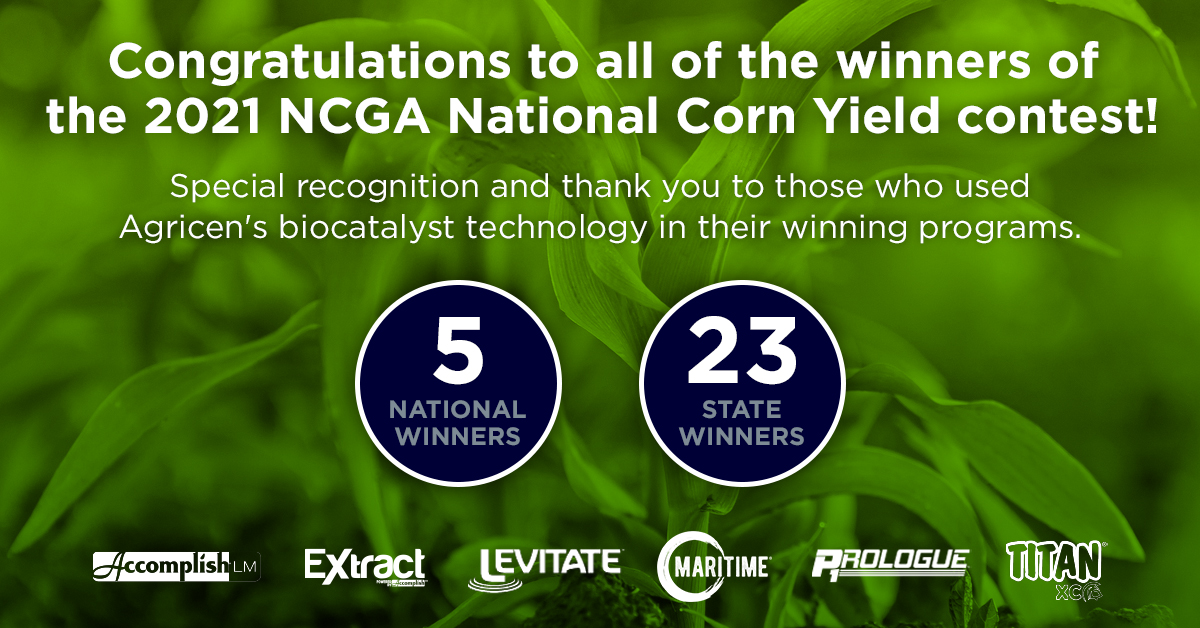

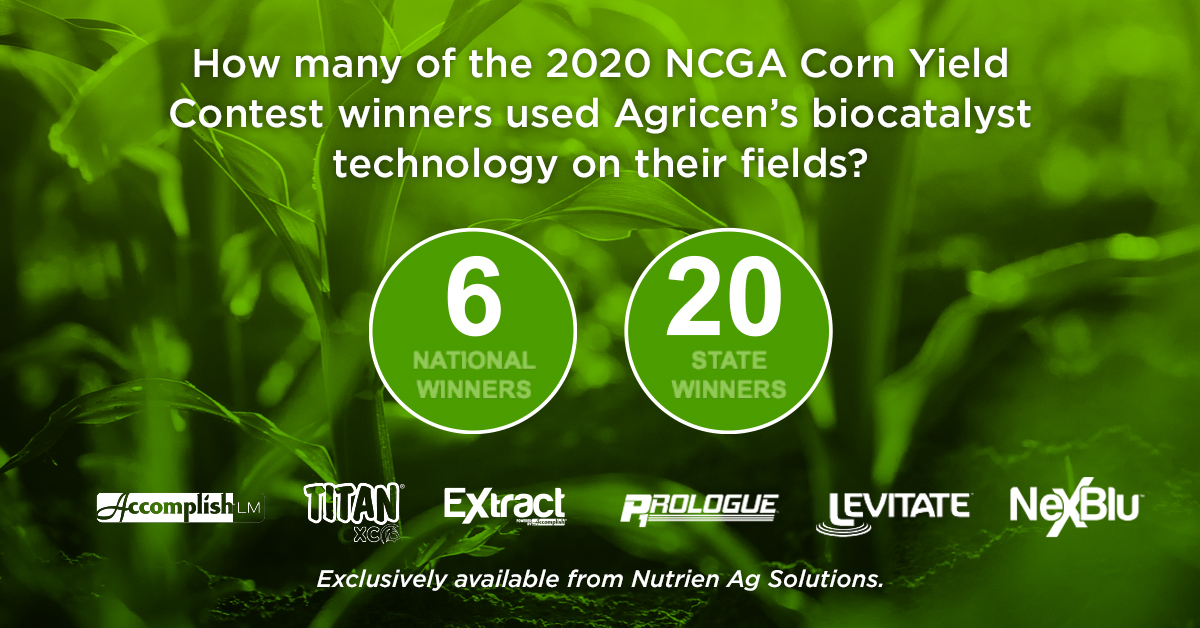

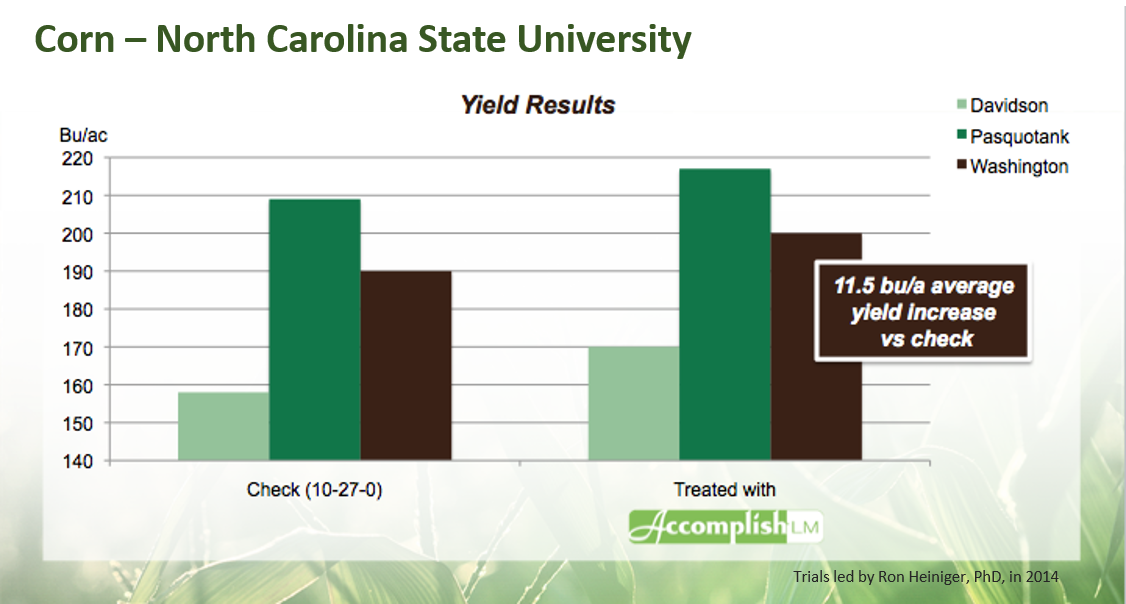

In 2018, no fewer than five national winners and seven state winners of the

In 2018, no fewer than five national winners and seven state winners of the  Don has been entering the NCGA Corn Yield Contest since 2003, when he noticed that he was already achieving yields comparable to the growers who were winning the contest. He has been the Michigan high yield champion for nine years in a row. In both 2017 and 2018,

Don has been entering the NCGA Corn Yield Contest since 2003, when he noticed that he was already achieving yields comparable to the growers who were winning the contest. He has been the Michigan high yield champion for nine years in a row. In both 2017 and 2018,  Kevin and Shawn have been entering the NCGA Corn Yield Contest since 2007, winning 12 national titles in the non-irrigated division. Both Kevin and Shawn have had

Kevin and Shawn have been entering the NCGA Corn Yield Contest since 2007, winning 12 national titles in the non-irrigated division. Both Kevin and Shawn have had

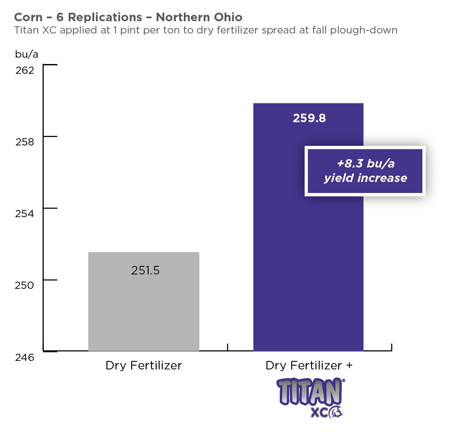

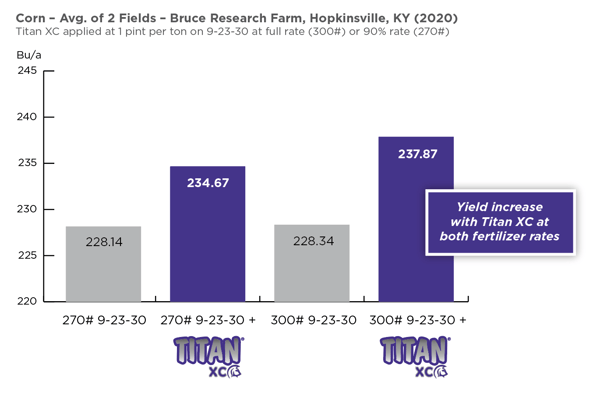

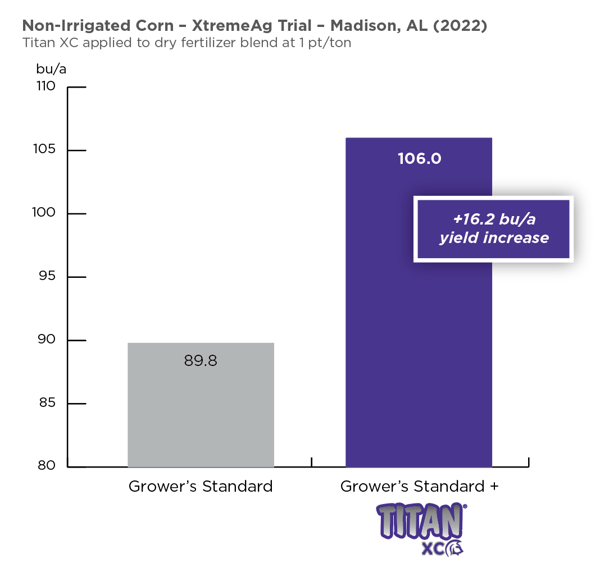

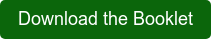

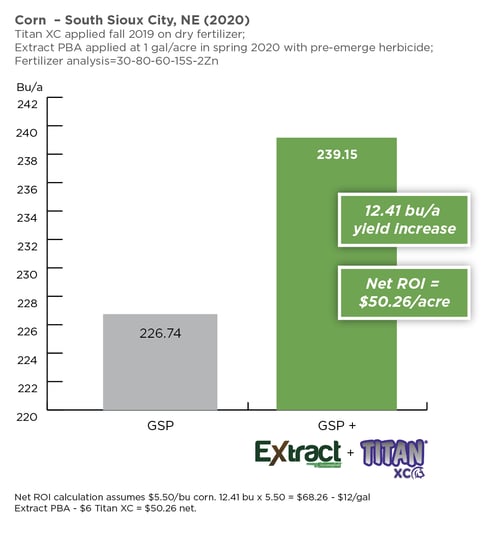

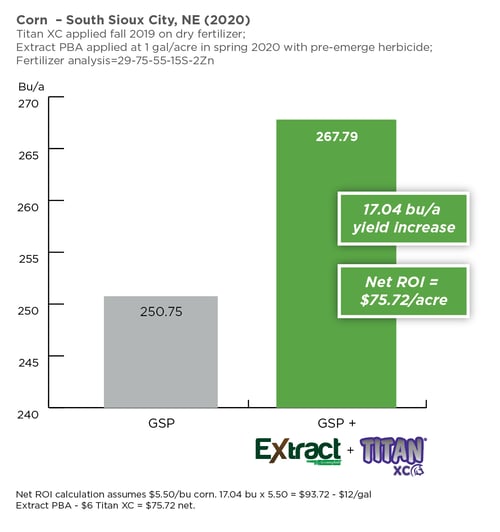

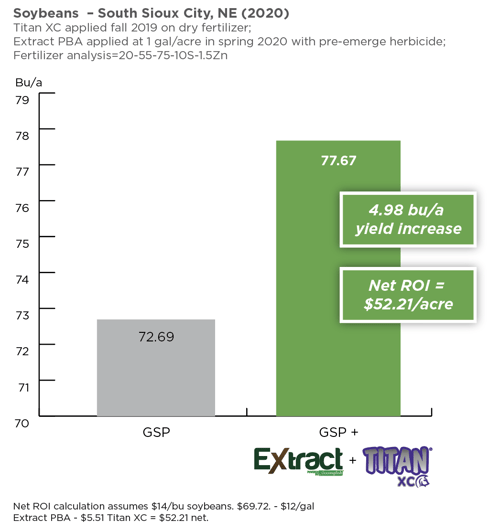

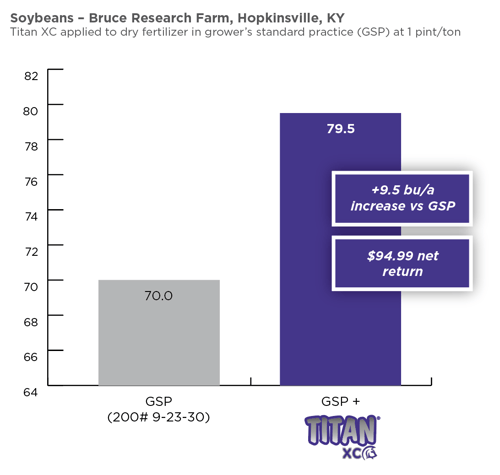

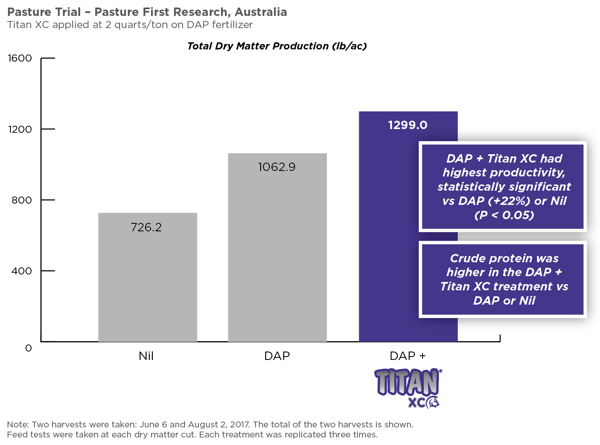

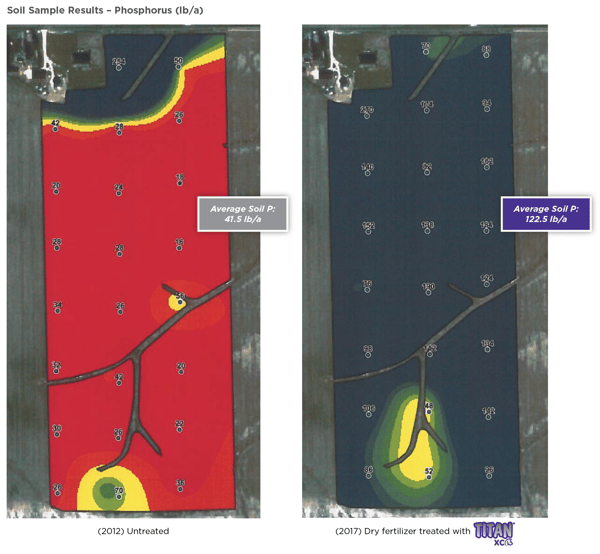

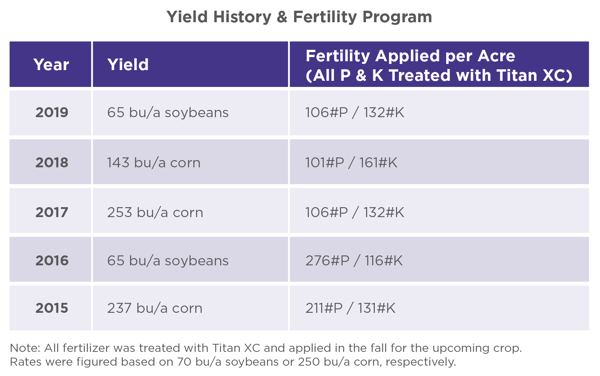

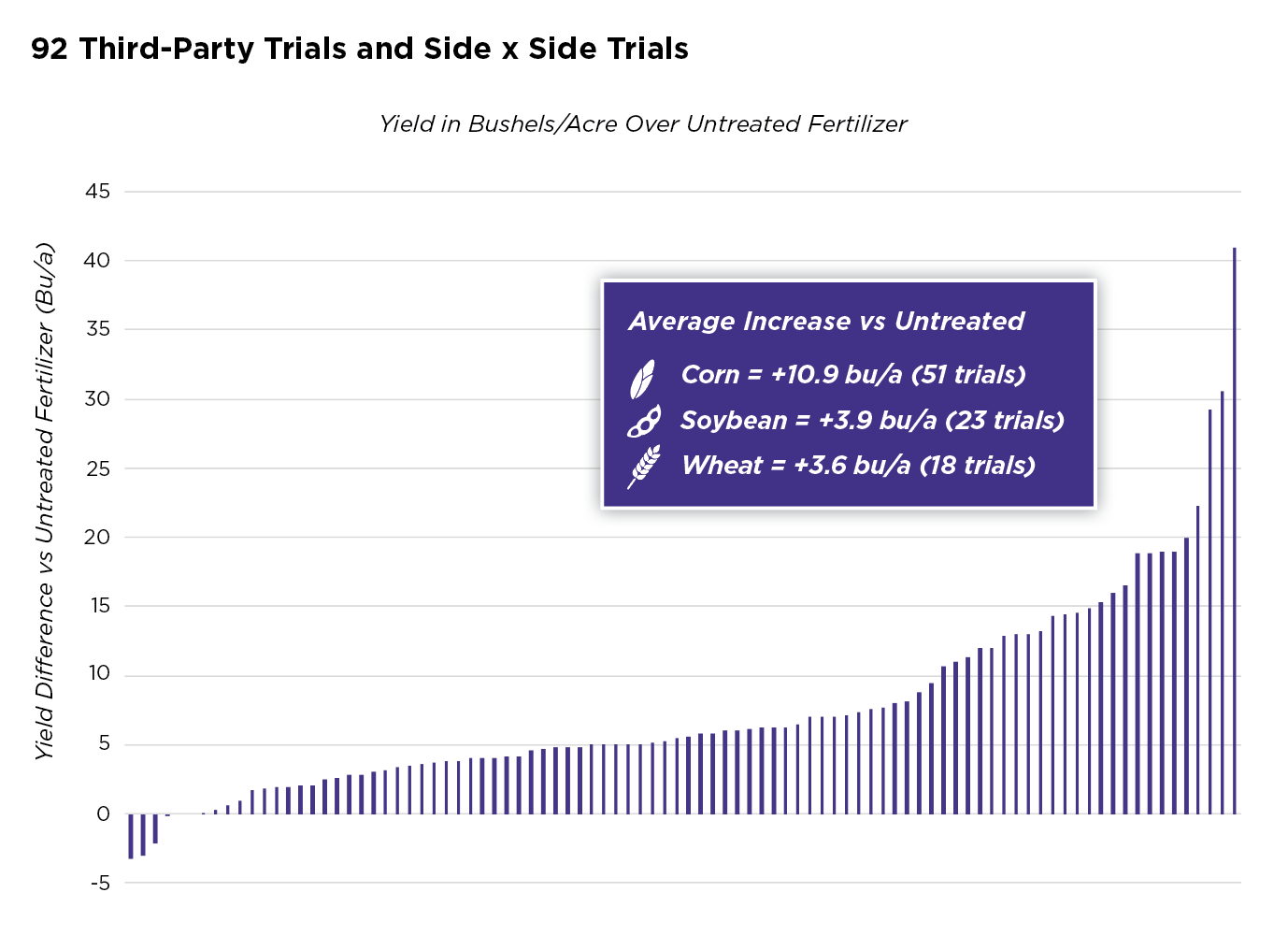

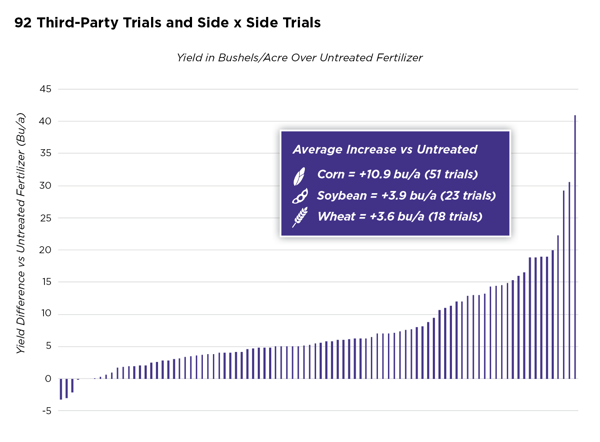

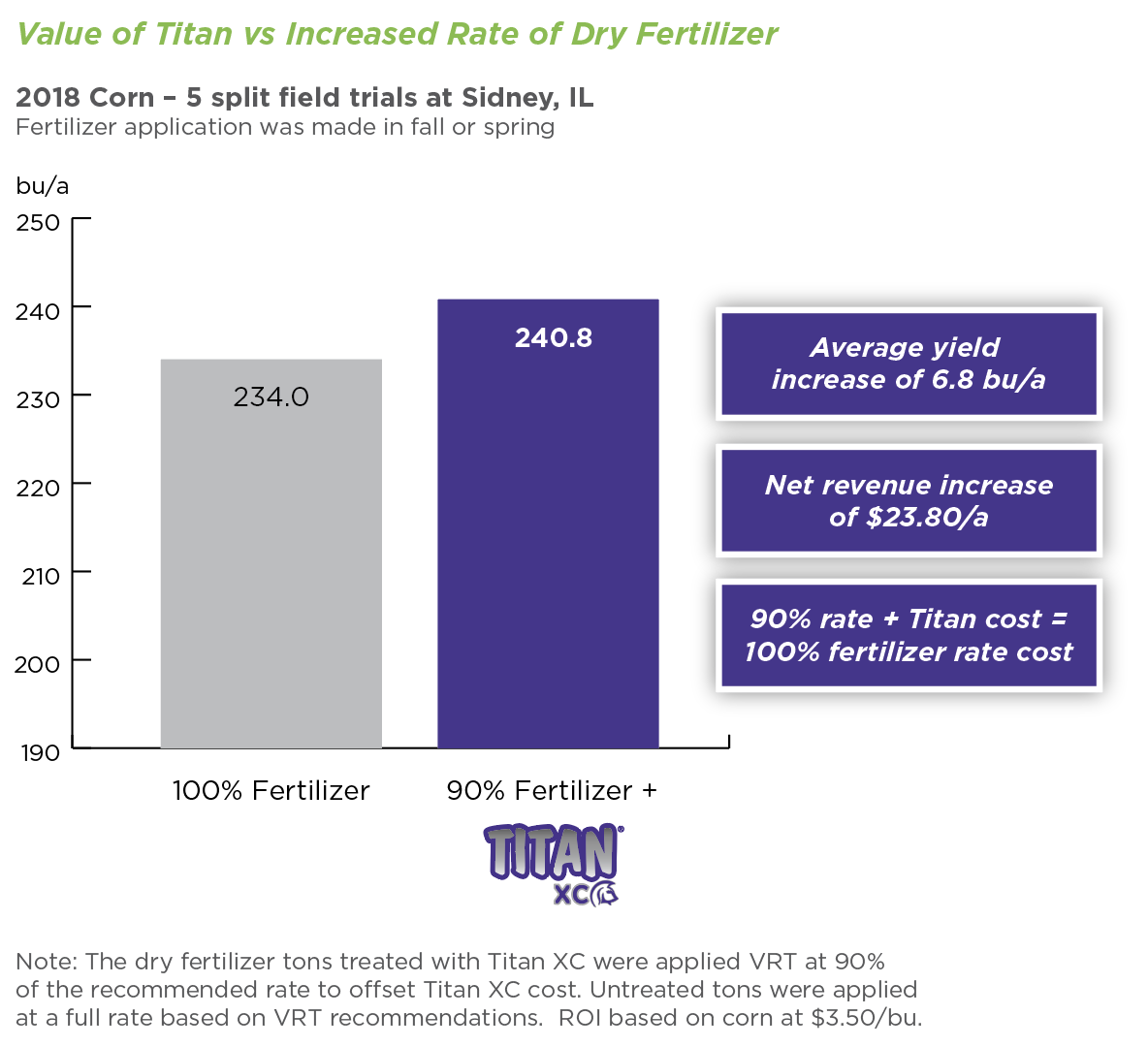

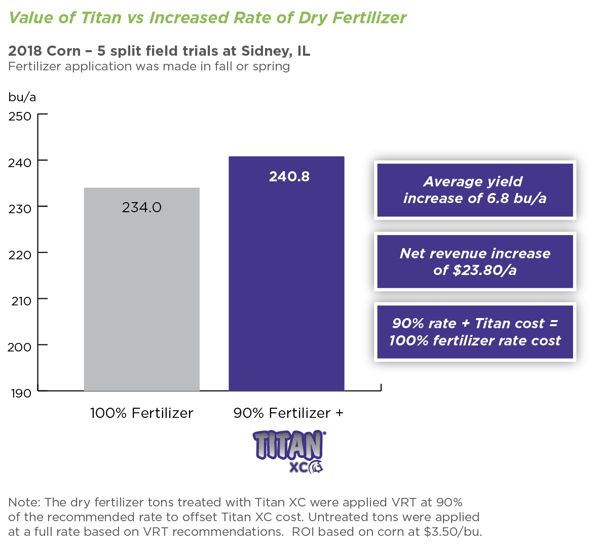

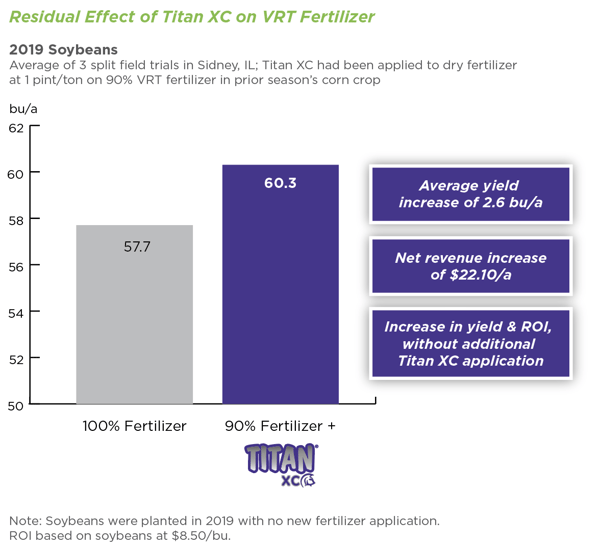

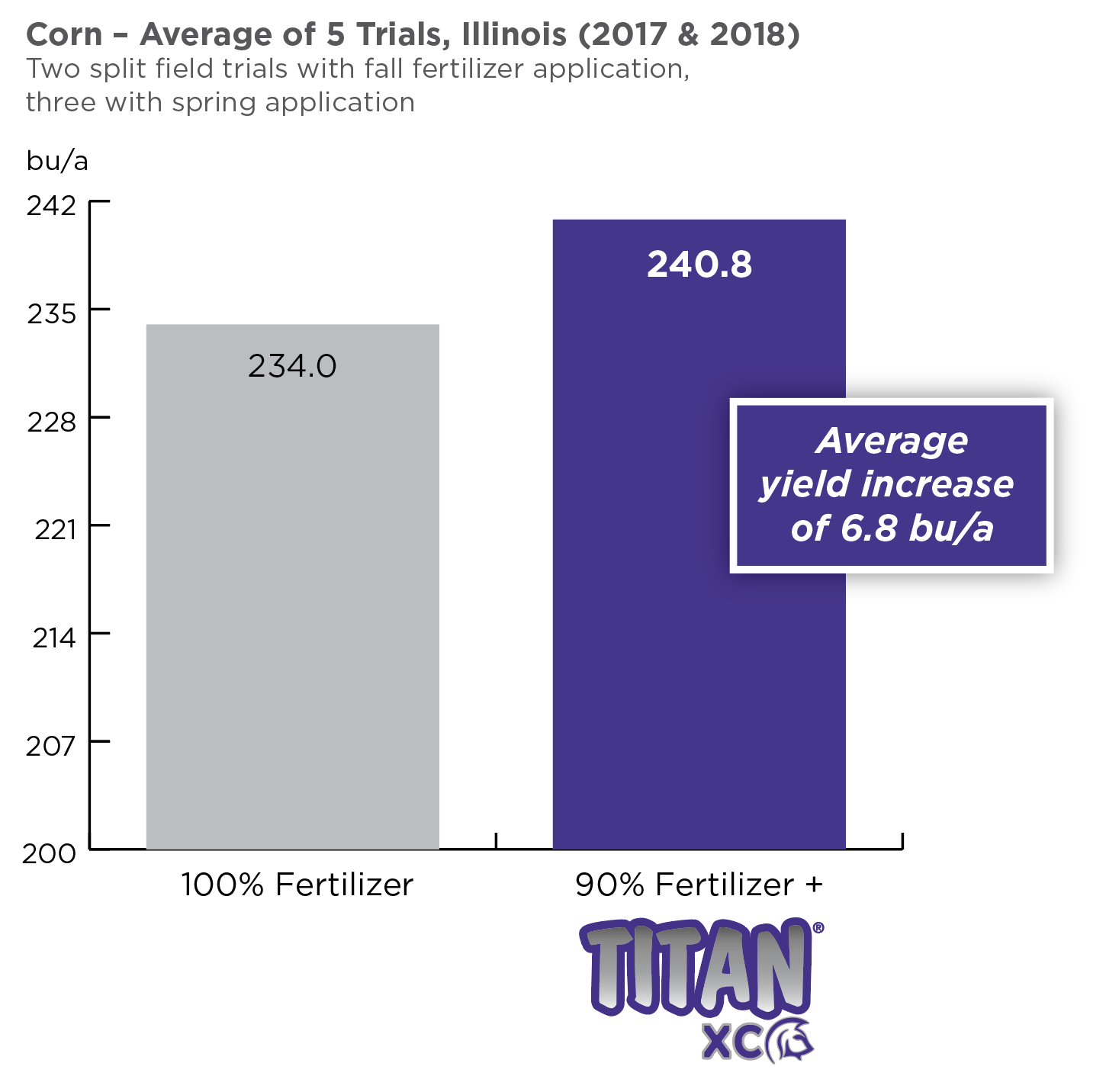

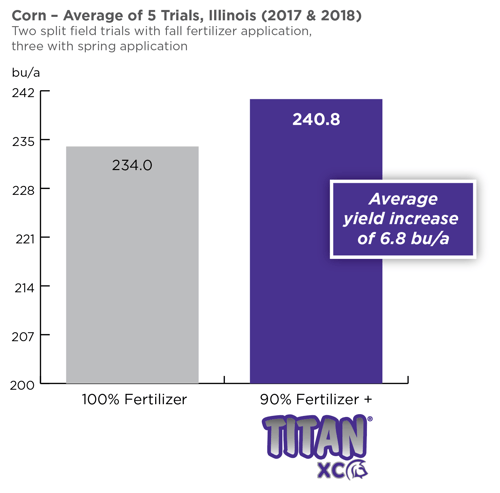

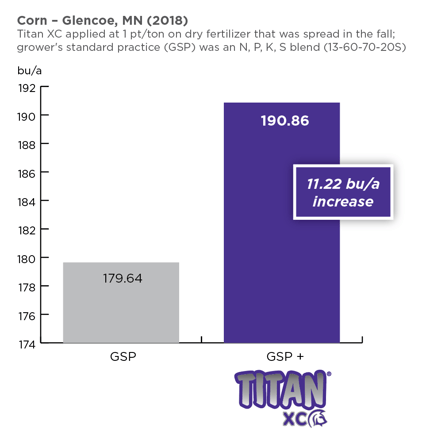

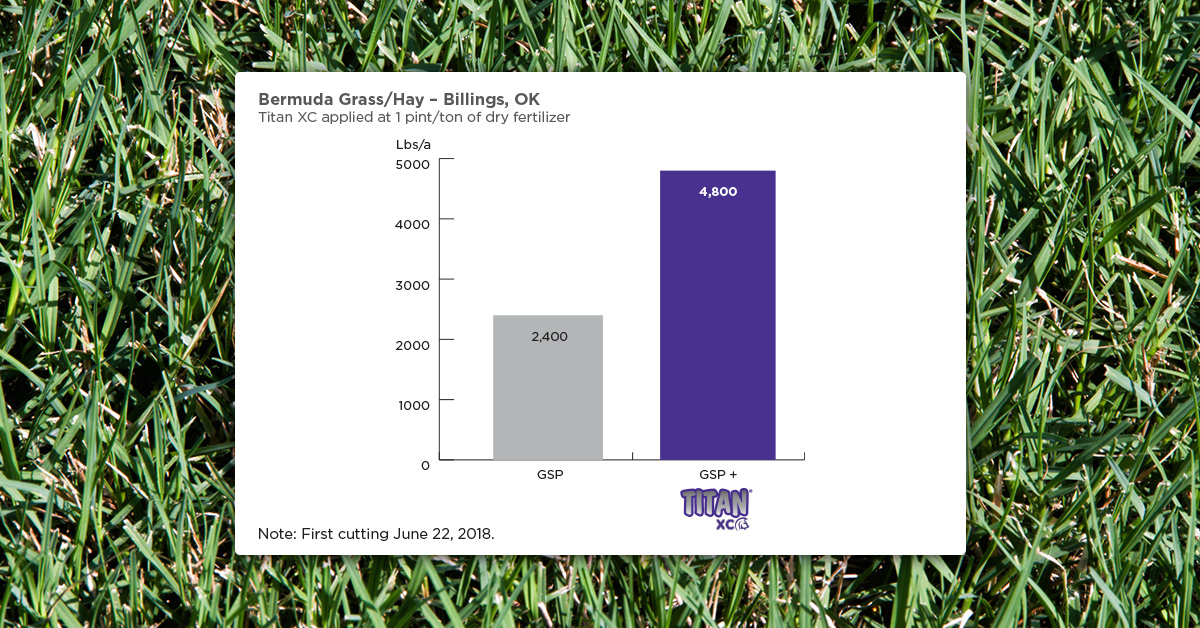

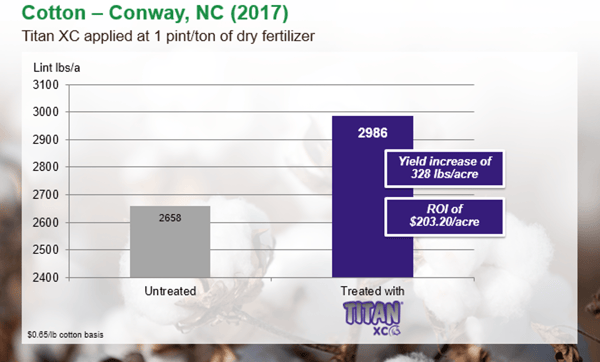

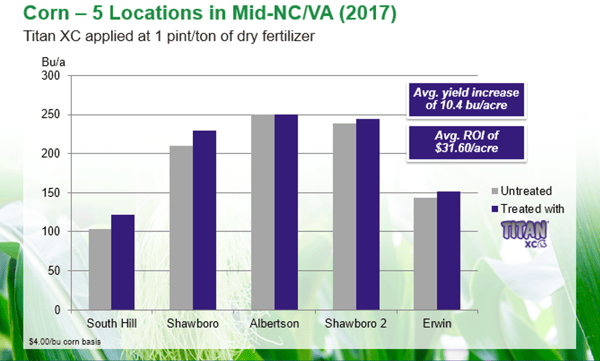

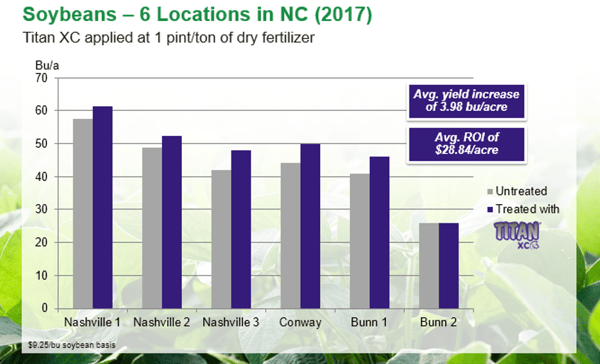

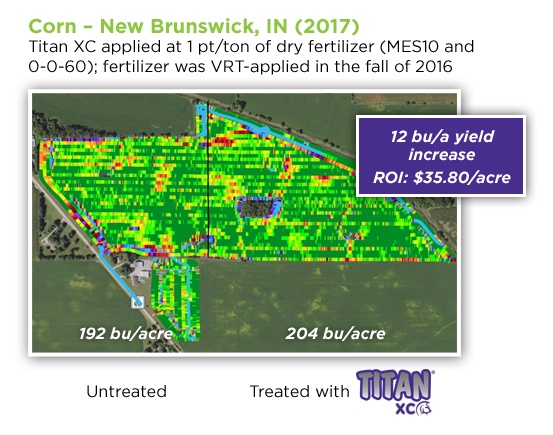

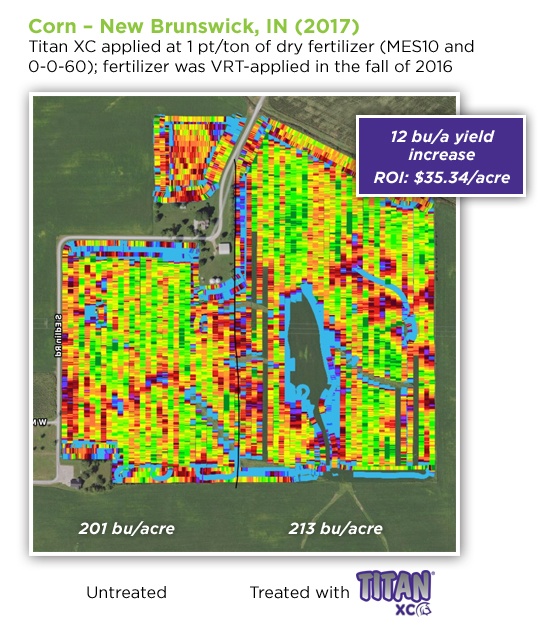

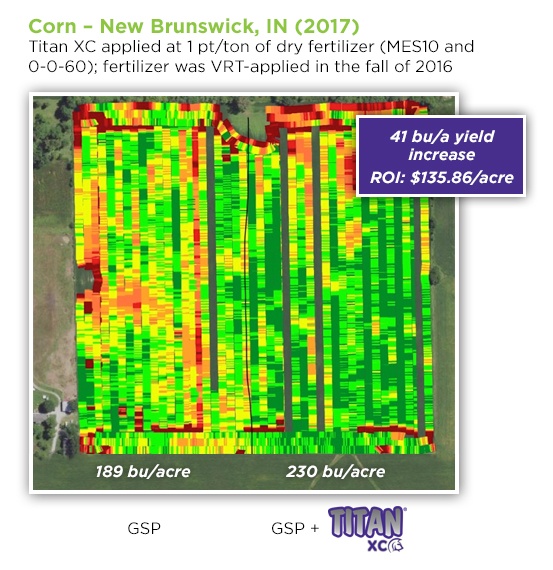

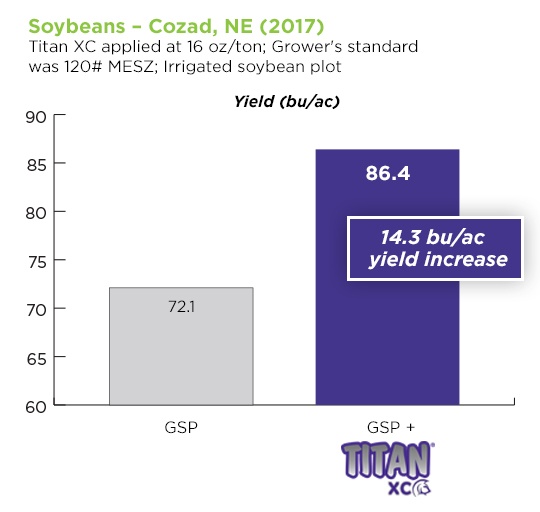

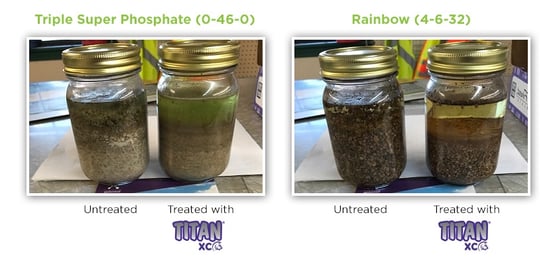

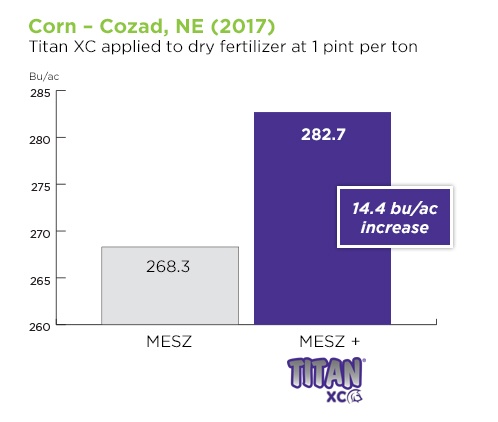

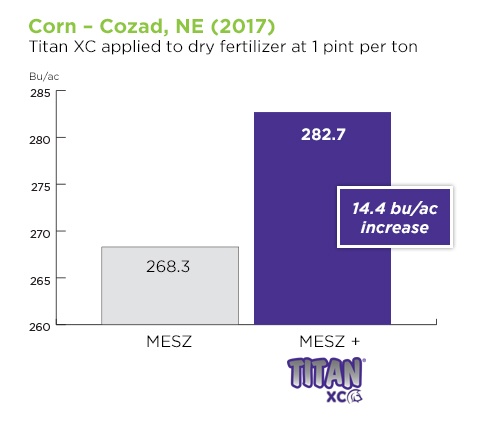

When it comes to fall dry fertilizer applications, poor soil conditions and bad weather can significantly decrease fertilizer efficiency. Treating dry fertilizer with

When it comes to fall dry fertilizer applications, poor soil conditions and bad weather can significantly decrease fertilizer efficiency. Treating dry fertilizer with

The

The

Cover crops provide many benefits that can improve the health of soil, water, and the following crop. However, they can also pose some drawbacks.

Cover crops provide many benefits that can improve the health of soil, water, and the following crop. However, they can also pose some drawbacks.

Jeff van Kalker, a tested operations and supply chain innovator, has joined Agricen as Director of Operations. In his new role, Jeff is responsible for overseeing safety, quality, capacity planning and logistics at the facilities where Agricen's

Jeff van Kalker, a tested operations and supply chain innovator, has joined Agricen as Director of Operations. In his new role, Jeff is responsible for overseeing safety, quality, capacity planning and logistics at the facilities where Agricen's

We are happy to welcome Smrithi Rajagopal as Agricen's Solutions Innovation Manager.

We are happy to welcome Smrithi Rajagopal as Agricen's Solutions Innovation Manager.

It’s spring, and newly germinated seedlings are revving their engines!

It’s spring, and newly germinated seedlings are revving their engines!

With plant health innovation at the core of our business, we are pleased to announce that

With plant health innovation at the core of our business, we are pleased to announce that

This year, Agricen celebrates 20 years of agricultural technology research, discovery and innovation aimed at sustainably improving crop yields. Two decades is no small feat in the agribusiness industry, and it's an even bigger achievement in our sector, focused on

This year, Agricen celebrates 20 years of agricultural technology research, discovery and innovation aimed at sustainably improving crop yields. Two decades is no small feat in the agribusiness industry, and it's an even bigger achievement in our sector, focused on  In the next decade, we look forward to continuing to deliver industry-leading solutions for agriculture and related industries that are 'Based on Nature, Built on Science.'

In the next decade, we look forward to continuing to deliver industry-leading solutions for agriculture and related industries that are 'Based on Nature, Built on Science.'

Our final

Our final

-CPS%20Clay%20Martz%20(right).jpg?width=500&name=2017%20NCGA%20National%20Winner%20Irrigated%20Corn-Grower%20Don%20Stall%20(left)-CPS%20Clay%20Martz%20(right).jpg)

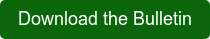

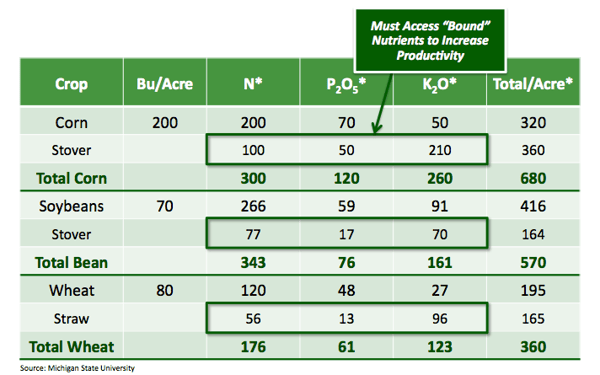

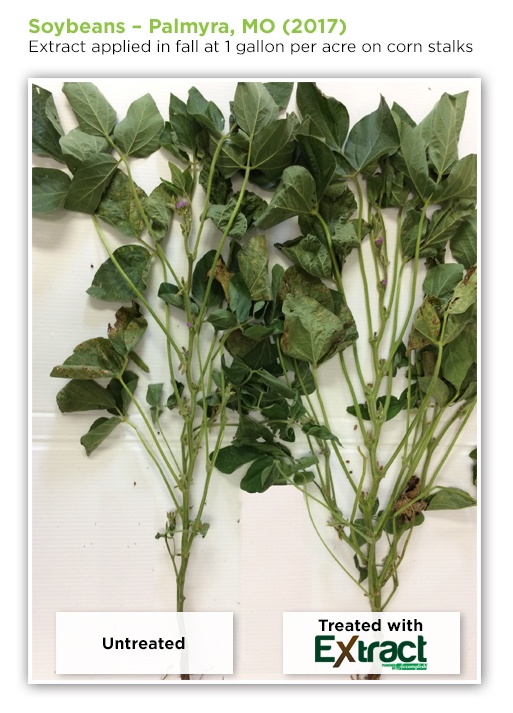

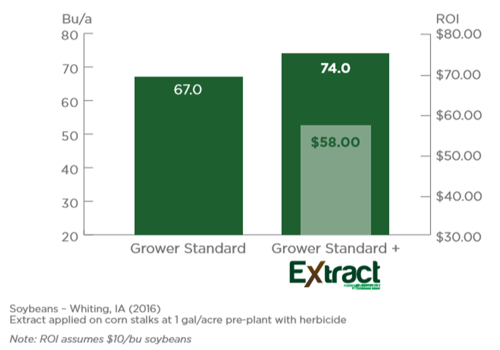

EXTRACT was sprayed on Nov. 29, 2017. This photo shows corn stalks from treated and untreated parts of the field that were pulled and split on March 23, 2018.

EXTRACT was sprayed on Nov. 29, 2017. This photo shows corn stalks from treated and untreated parts of the field that were pulled and split on March 23, 2018.

![[Data] Titan XC Proves Agronomic Benefit in Cotton, Corn & Soybeans](https://blog.agricen.com/hubfs/Cotton-Conway-NC-Titan-XC-2017.png)

![[Trial] Titan XC Provides 14 Bushel Yield Advantage in Soybeans](https://blog.agricen.com/hubfs/TitanXC-soybeans.jpg)

![[Video Roundup] How Farmers Improve Ag Productivity & Sustainability](https://blog.agricen.com/hubfs/Agriculture%20Videos.png)

![[Corn Trial] Bigger Roots & Healthier Stalks with Titan XC](https://blog.agricen.com/hubfs/corn-TitanXC-1.jpg)

![[Video] Building Sustainable Agriculture Programs](https://blog.agricen.com/hubfs/Sustainable_Video.png)

![[Hoosier Ag Today] Extending Nutrients for Soybeans This Year](https://blog.agricen.com/hubfs/Soybeans%20in%20farm%20field,%20early%20September%20in%20Illinois.jpeg)

![[RFD IL Radio] Improving Soybean Performance with Spring Applications](https://blog.agricen.com/hubfs/soybeans-1.png)

![[Ohio AgNet] Improve Soybean Yield by Addressing Nutrient Availability](https://blog.agricen.com/hubfs/OhioAgnet_1200x628.jpg)

![[AgWatch Interview] How Spring Soybean Programs Can Benefit Farmers](https://blog.agricen.com/hubfs/AgWatch_1200x628%20%281%29.jpg)

AgWatch

AgWatch![[Video] Make Every Nutrient Count with Extract PBA](http://blog.agricen.com/hubfs/soybean%20field.png)

Biostimulants

Biostimulants

![[Video] Fertilizer Breakdown with Titan XC](http://blog.agricen.com/hubfs/prill.png)

![[Trial Data] Extract PBA Brings Big Returns on Two Crops in One Year](https://blog.agricen.com/hubfs/soybean-blog-header-01.jpg)

![Faster Fertilizer Prill Breakdown with Titan XC [Demo]](http://blog.agricen.com/hubfs/Titan_XC_increase_in_fertilizer_breakdown.png)

Jeff Frank, a fourth generation farmer from Auburn, Iowa, grows corn and soybeans on a 1,200-acre century farm that he and his wife operate. He is an avid drone enthusiast and dealer (hear him speak more about drones and farming in

Jeff Frank, a fourth generation farmer from Auburn, Iowa, grows corn and soybeans on a 1,200-acre century farm that he and his wife operate. He is an avid drone enthusiast and dealer (hear him speak more about drones and farming in

Titan XC

Titan XC

We are proud to share the news that “

We are proud to share the news that “

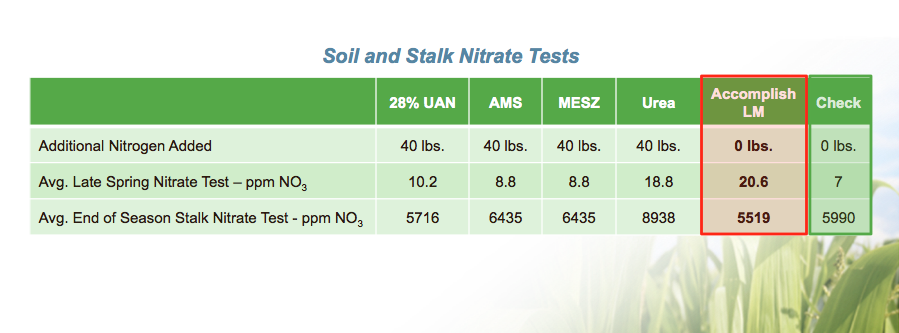

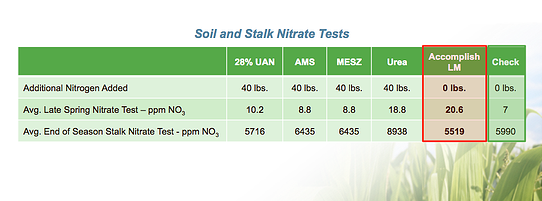

We all know the importance of nitrogen in producing a high-yielding corn crop, but it is easy to forget or even ignore that the timing of an nitrogen application can be the key to maximizing its benefits.

We all know the importance of nitrogen in producing a high-yielding corn crop, but it is easy to forget or even ignore that the timing of an nitrogen application can be the key to maximizing its benefits.

It turns out that the new root is constantly making choices about where and when to grow based on the environment it encounters. Guided by its “

It turns out that the new root is constantly making choices about where and when to grow based on the environment it encounters. Guided by its “

Growers today are confronted with a large number of fertilizer additive options, including

Growers today are confronted with a large number of fertilizer additive options, including

![Prove It to Me [Film]: Follow 5 Farmers Through the Growing Season](http://blog.agricen.com/hubfs/ProveItSmall.png)

![Frequently Asked Questions About Extract PBA [New Booklet]](http://blog.agricen.com/hubfs/Extract_FAQ_Image.jpg)

Plants are constantly responding to their senses. They can touch, smell, taste and otherwise sense water, food and predators—and they can remember. Of course, they don’t do all of this exactly the way a human does, but they do respond to the messages they receive from the world around them to survive, thrive and reproduce—much the way we do.

Plants are constantly responding to their senses. They can touch, smell, taste and otherwise sense water, food and predators—and they can remember. Of course, they don’t do all of this exactly the way a human does, but they do respond to the messages they receive from the world around them to survive, thrive and reproduce—much the way we do.

![[Video] Grower Stories: Brandon Burkhart, Iowa Corn & Soybean Farmer](https://embed-ssl.wistia.com/deliveries/11d6f78c55f64a1eb431edb32af22546b27b2525.jpg?image_play_button=true&image_play_button_color=74a0bce0&image_crop_resized=440x248)

![[Video] How to Use This Season’s Residue to Feed Next Season’s Crop](https://embed-ssl.wistia.com/deliveries/150509fe57db88b4dc437a87068ca5a254c0e74c.jpg?image_play_button=true&image_play_button_color=71b871e0&image_crop_resized=440x248)

![[Trial Results] Soybean Startup Program Is a Standout in the Field](https://blog.agricen.com/hubfs/blog-files/soybean_startup_1.jpg)

In the last few decades “agricultural sustainability” has emerged as an industry catchphrase. We all agree that we should be doing it, but what does it really mean? Before we can start practicing “agricultural sustainability” we must define what it means. Let’s take a look at a few existing definitions.

In the last few decades “agricultural sustainability” has emerged as an industry catchphrase. We all agree that we should be doing it, but what does it really mean? Before we can start practicing “agricultural sustainability” we must define what it means. Let’s take a look at a few existing definitions.

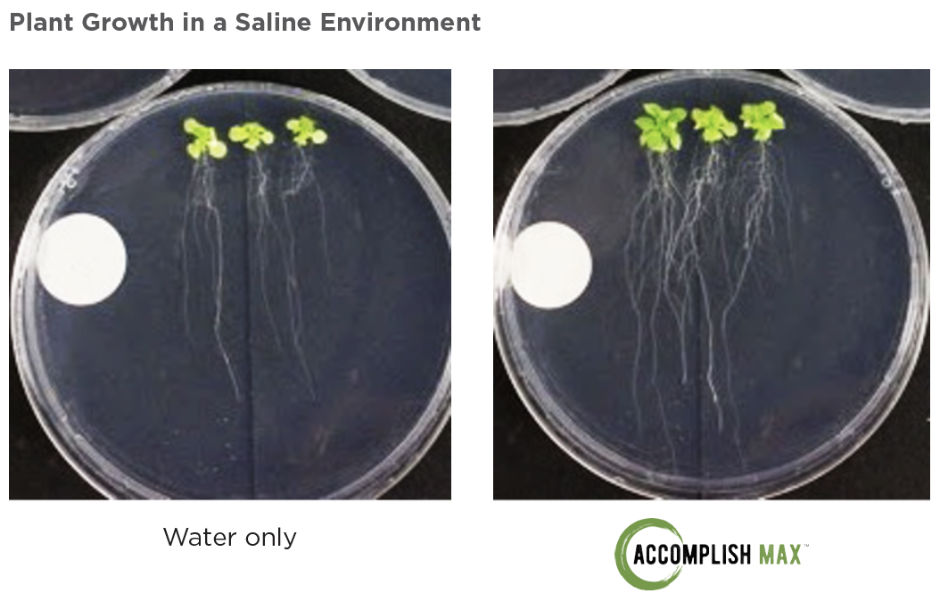

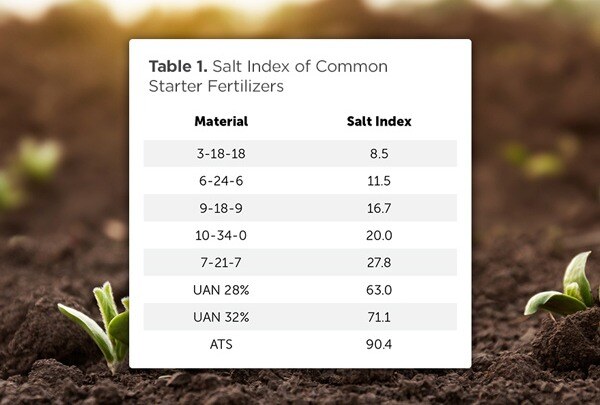

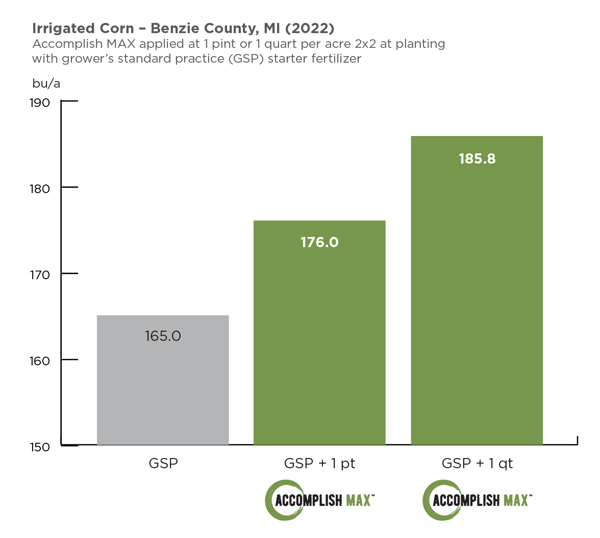

I’ve never used a starter program for my soybean plants. Nutrient deficiencies are not as common as they are in corn, and the salt in traditional fertilizers can harm the seedlings. Why would I consider a soybean starter program now?

I’ve never used a starter program for my soybean plants. Nutrient deficiencies are not as common as they are in corn, and the salt in traditional fertilizers can harm the seedlings. Why would I consider a soybean starter program now?

![[Video] Understanding the Science Behind Ag Biochemicals](https://blog.agricen.com/hs-fs/hub/269648/file-675980597-jpg/blog-files/field.jpg)

In this short video,

In this short video,