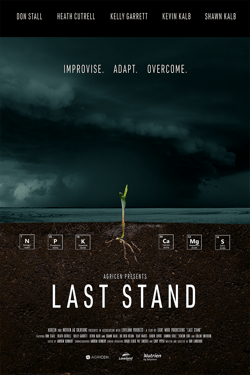

Farmers have a story to tell, and we wanted to capture it. During the 2020 growing season, Agricen hired a film crew to document the experiences of growers from four different farm operations in the United States. The result is Last Stand, a movie that follows some of America's top farmers as they try to grow the highest yields possible in a season full of challenges. The film can be watched by visiting LastStand.ag.

Farmers have a story to tell, and we wanted to capture it. During the 2020 growing season, Agricen hired a film crew to document the experiences of growers from four different farm operations in the United States. The result is Last Stand, a movie that follows some of America's top farmers as they try to grow the highest yields possible in a season full of challenges. The film can be watched by visiting LastStand.ag.

“While you can never predict what the growing season will be like, the 2020 season certainly did manage to throw many surprises into the mix. Excessive rain and hurricanes, the historic derecho in Iowa and across the upper Midwest – and that’s just the weather,” says Michael Totora, president and CEO of Agricen. “We think this is an important film that not only gives viewers a unique glimpse into the lives of the featured farmers, but also into the lives of farmers across the U.S. in 2020.”

The farmers featured in the film have a passion for farming and produced some of the highest corn yields in the nation in recent years. They also have the humor, grit and resilience to help them succeed at the job.

In Last Stand, you’ll meet:

- Don Stall – A former Marine, Don still reflects on the lessons he learned in the Marine Corps to help him face the challenges of being a farmer. Don farms in Michigan.

- Kelly Garrett – Kelly farms with his father and three sons in Iowa, where they work cattle and grow corn, soybeans and winter wheat.

- Heath Cutrell – Heath is a third-generation corn, soybean and wheat grower farming in Virginia and across the state line in North Carolina.

- Kevin and Shawn Kalb – Kevin and Shawn farm with their children in Southern Indiana, where they produce corn, soybeans and turkeys, and can often be found smashing state and national corn yield records.

- Dr. Fred Below & Connor Sible – Dr. Below and PhD student Connor Sible are from the Crop Physiology Laboratory at the University of Illinois at Urbana-Champaign, where they research factors influencing corn and soybean productivity.

Pictured above are top producers Don Stall (top L), Kelly Garrett (top R), Heath Cutrell (bottom L) and Kevin and Shawn Kalb (bottom R).

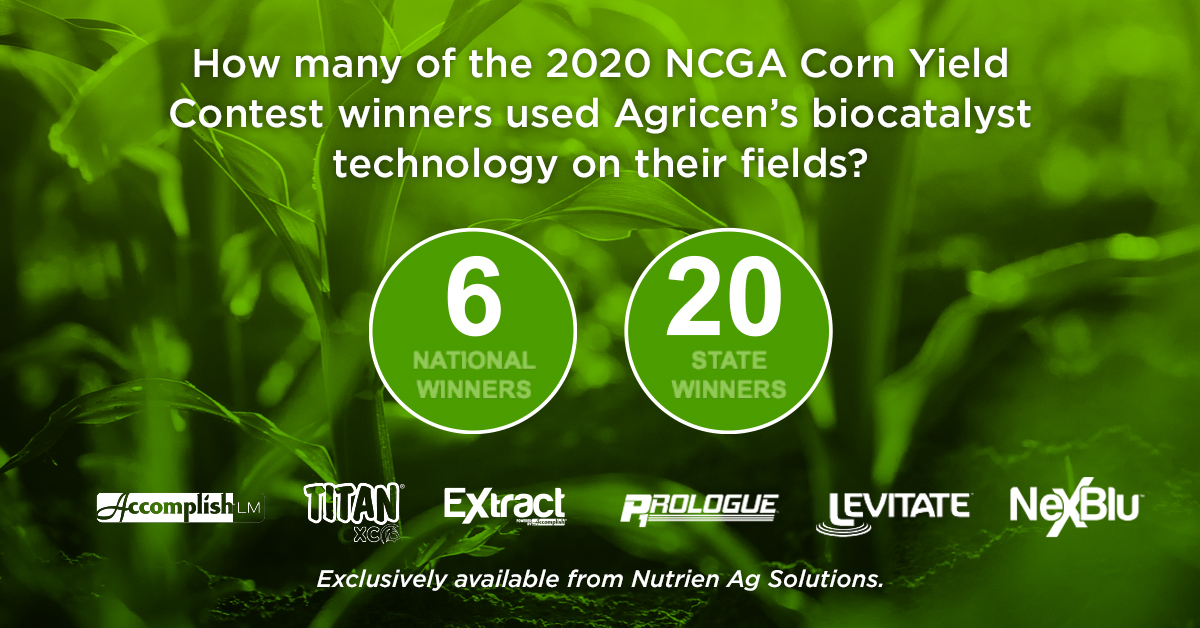

Another factor that ties the growers together is that they have used Agricen's product technologies in their high-yielding programs.

“Several years ago, we noticed that a number of growers with top corn yields at the state and national levels used our product technologies in their production programs,” says Totora. “With Last Stand, we set out to dig into that, but it quickly became much more. Their stories, as captured in the film, are deeply personal, yet also familiar to farmers everywhere.”

Last Stand, filmed by agriculture documentary veterans Light Work Productions, is the second long-form film about farming developed by Agricen. Agricen’s previous film about agriculture, Prove It to Me, which followed five farmers from Arkansas and Iowa during the 2015 growing season, is also available to view.

Explore the Last Stand trailers or visit laststand.ag to watch the full film.

![[WITY Radio] Sometimes the Answer Is Not More Fertilizer](https://blog.agricen.com/hubfs/09-21-down-on-the-farm.jpg)

Cathy and Martin Quigley struck gold in the

Cathy and Martin Quigley struck gold in the

Does a pre-emergence application of

Does a pre-emergence application of