RFD: How do we get the best performance out of soybeans? The product that we’re talking about is Extract. First things first, Scott, what is Extract?

Scott Lay: Extract is a fertilizer biocatalyst that we are positioning in soybeans, and it is unique to Nutrien Ag Solutions/Loveland Products. Extract is designed to help speed up nutrient mineralization and free up additional fertility for the growing crop so it can realize its full yield potential.

RFD: Interesting that it’s a fertilizer biocatalyst, but it’s not applied with fertilizer. How does that work?

Scott: It is often applied with liquid fertilizers, particularly in corn and wheat. But in this instance, we are applying it with soybean herbicides. This is simply because across Illinois and the greater part of the Midwest, fertilizing for a soybean crop isn’t an established practice. The presence of Extract allows growers to mineralize more nutrients, pulling in more of the nutrients from the soil that already exist there.

RFD: So Extract is in a liquid form?

Scott: It is in a liquid form, so it’s very easy to use, and it can be tank-mixed with virtually any combination of herbicides and/or liquid fertilizers.

RFD: So if I’m about to perform my burndown as I anticipate planting, I can tank mix it and be off and running?

Scott: That’s correct. It’s best use in terms of timing in soybeans is early season, either prior to planting the crop or, in some instances, immediately after planting the crop, but prior to emergence.

RFD: Sometimes just getting soybeans to emerge can be a challenge, so I assume this helps with that?

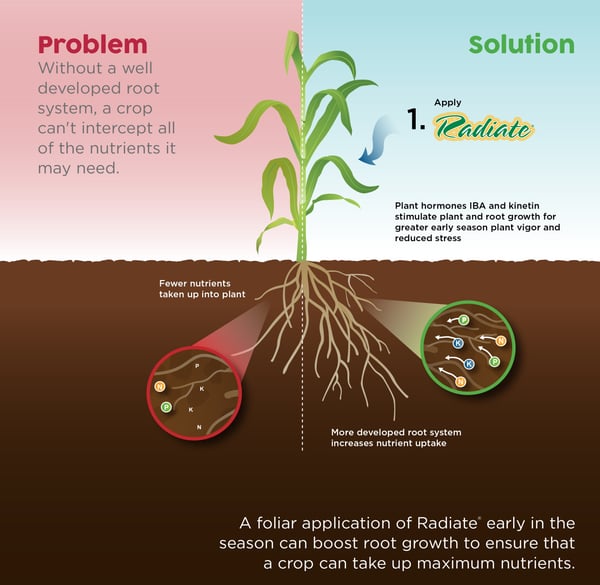

Scott: Very much so, and I think you hit it right on the head. Soybeans are a little more of a fragile crop relative to corn, particularly early season. Getting that even and consistent emergence–that early season vigor and plant health–is very critical, not just in terms of establishing stand count, but also in allowing each and every plant to realize more of its yield potential come September and October.

RFD: I was looking at some notes here about Extract delivering nutrients to the plant when yield is determined.

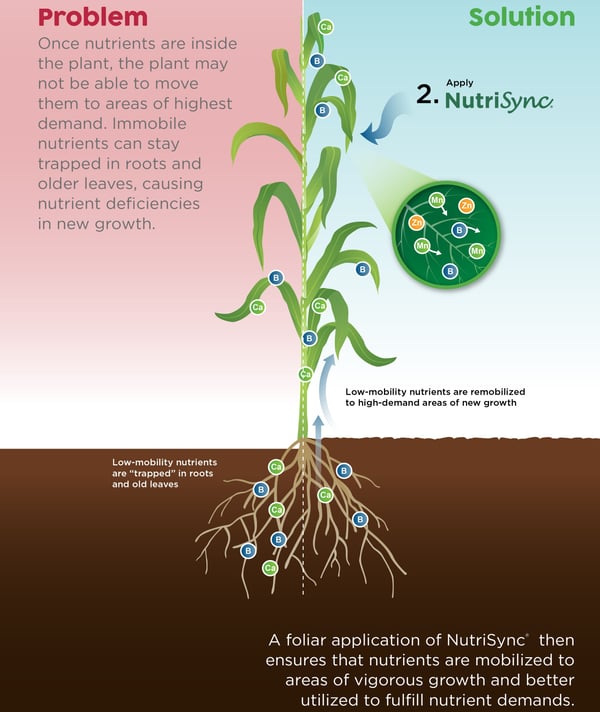

Scott: Soybeans are a complex biological bean. While early season emergence is critical, nutrient availability is key in terms of determining the yield of that soybean crop. Ninety percent of all nutrients consumed in a soybean plant are taken up from bloom through physiological maturity. When we utilize Extract, we've found that there are more nutrients in a plant-available form throughout the season, including into that July/August timeframe when most nutrients are consumed.

RFD: So we put it in now, and later we have those nutrients available. The nutrients are already in that soil, so it’s just a matter of getting them into that crop?

Scott: That’s very true. Step one, of course, is applying nutrients. Certainly a number of dollars are expended in that effort. But that’s not always a guarantee that the nutrients find themselves in a plant-available form that the crop can utilize. Extract, while it’s not magic, simply accelerates that process of releasing nutrients that are otherwise bound up by metals and calcium, and perhaps limited by pH or weather. It helps make the plant more efficient in its end result.

RFD: You have done trials?

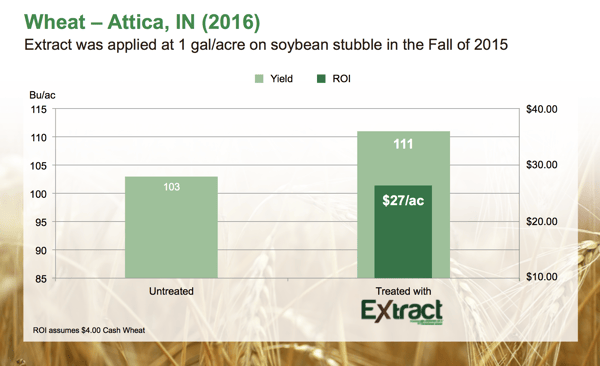

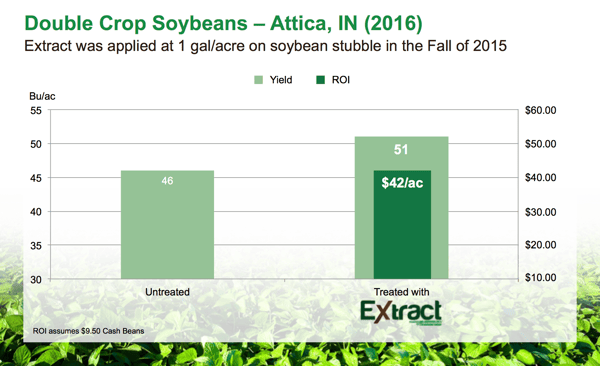

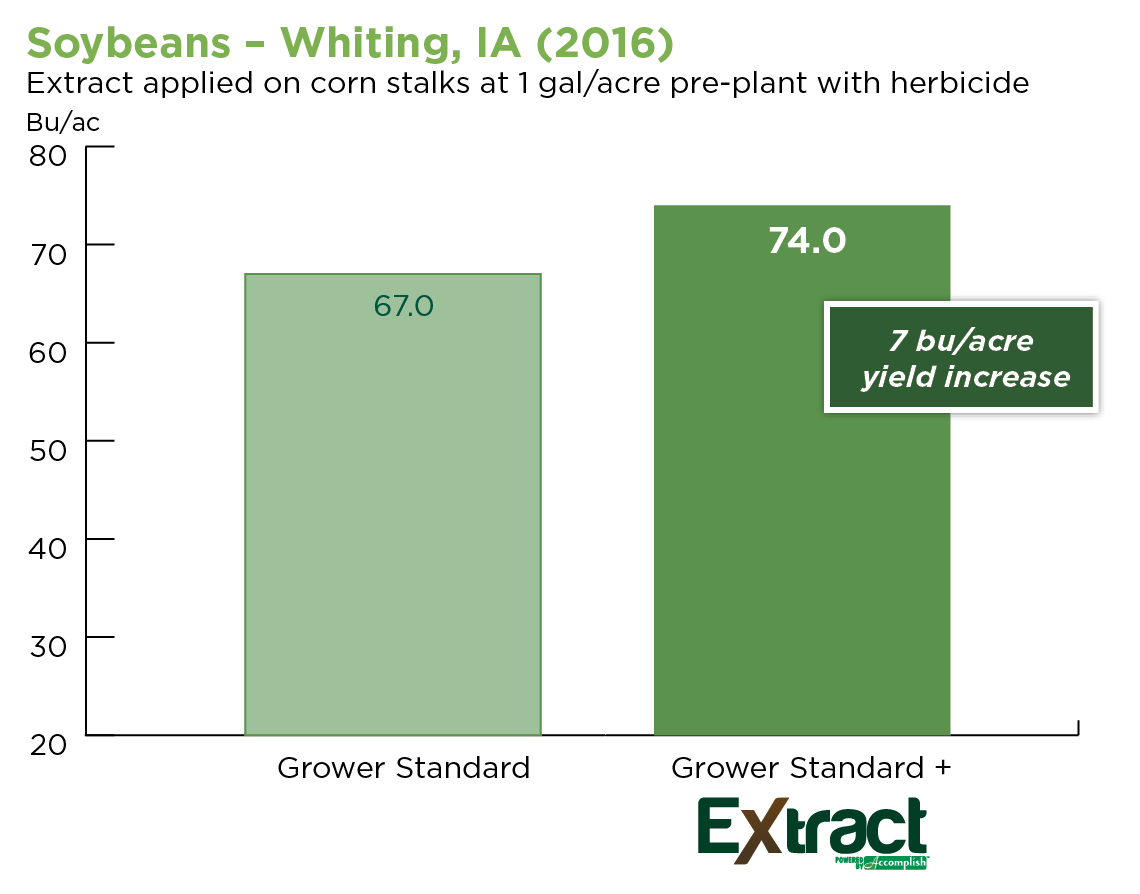

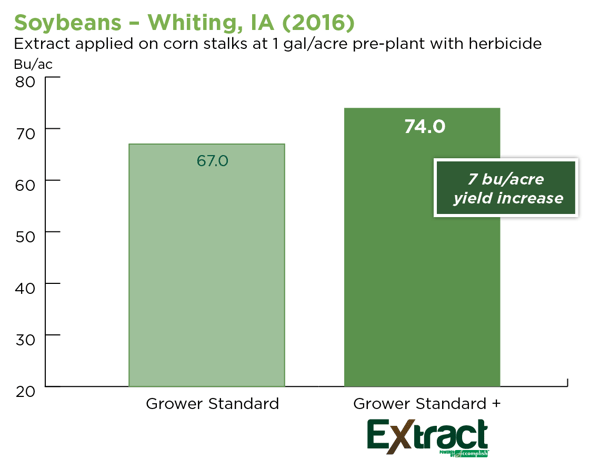

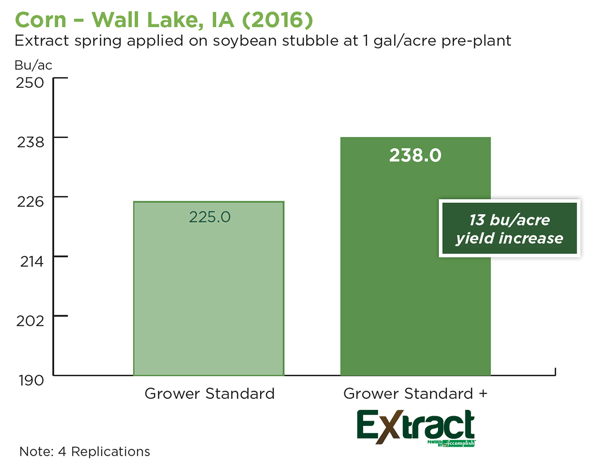

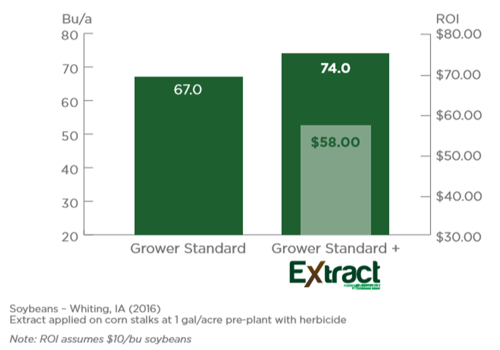

Scott: We have a lot of trials. Over the last several years, a number of land grant institutions across the Midwest, other third-parties and our folks at Nutrien Ag Solutions Services have conducted probably in the range of 100 to 150 trials so far. We’ve seen some very consistent results when we’ve used Extract.

RFD: What about return on investment? Would this lead to an increased yield bump? Because it is still an input, so we would need to cover that input.

Scott: Well said, it's absolutely an input. We recognize that the name of the game is return on investment. What we’ve found across our trials and from in-field use is that the positive yield result has averaged right at about 4.5 bushels per acre of increased soybean yield. It’s a very consistent return on investment given the minimal cost for Extract. In relative terms, it costs about 1.2 bushels of increased yield to pay for the Extract application.

RFD: Where does one find Extract?

Scott: You can find the product at any Nutrien Ag Solutions retail store across the Midwest, and our local sales representatives and agronomists would be happy to have a discussion about Extract and how it may potentially fit into a particular farmer’s operation.

![[Hoosier Ag Today] Extending Nutrients for Soybeans This Year](https://blog.agricen.com/hubfs/Soybeans%20in%20farm%20field%2c%20early%20September%20in%20Illinois.jpeg)

![[RFD IL Radio] Improving Soybean Performance with Spring Applications](https://blog.agricen.com/hubfs/soybeans-1.png)

![[Ohio AgNet] Improve Soybean Yield by Addressing Nutrient Availability](https://blog.agricen.com/hubfs/OhioAgnet_1200x628.jpg)

![[AgWatch Interview] How Spring Soybean Programs Can Benefit Farmers](https://blog.agricen.com/hubfs/AgWatch_1200x628%20(1).jpg)

AgWatch

AgWatch

![[Video] Fertilizer Breakdown with Titan XC](https://blog.agricen.com/hubfs/prill.png)

![[Trial Data] Extract PBA Brings Big Returns on Two Crops in One Year](https://blog.agricen.com/hubfs/soybean-blog-header-01.jpg)