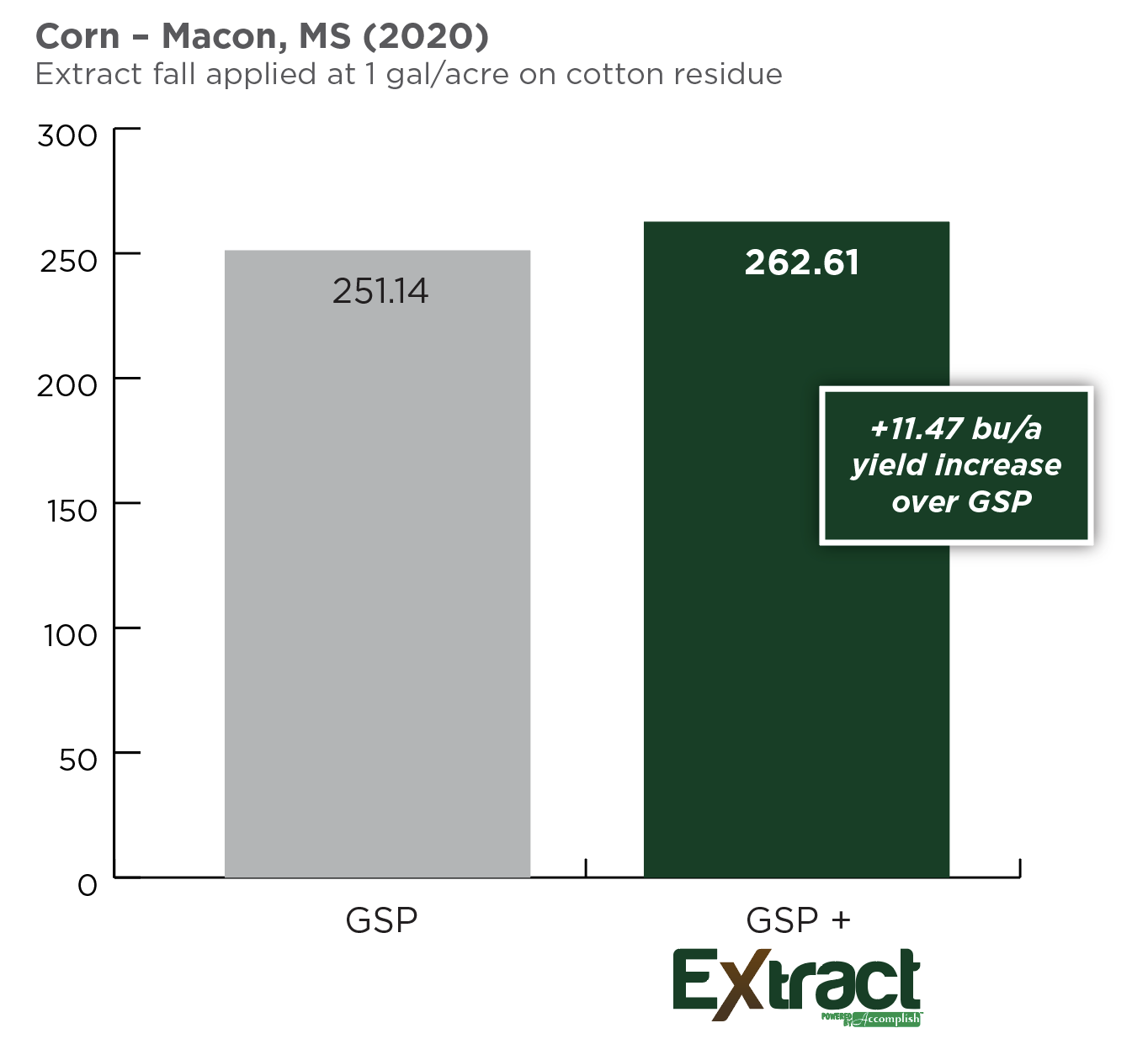

Yield success for a grower near Macon, Mississippi started in the fall when he applied 1 gallon per acre of EXTRACT PBA (with 1 gallon/acre of UAN 32 +15 gallons/acre of water) on cotton residue from his harvested crop.

The grower planted corn the following spring. Where EXTRACT had been used, he realized a yield increase of +11.47 bushels per acre compared to the check, as well as a net ROI of over $30 per acre with his EXTRACT application.

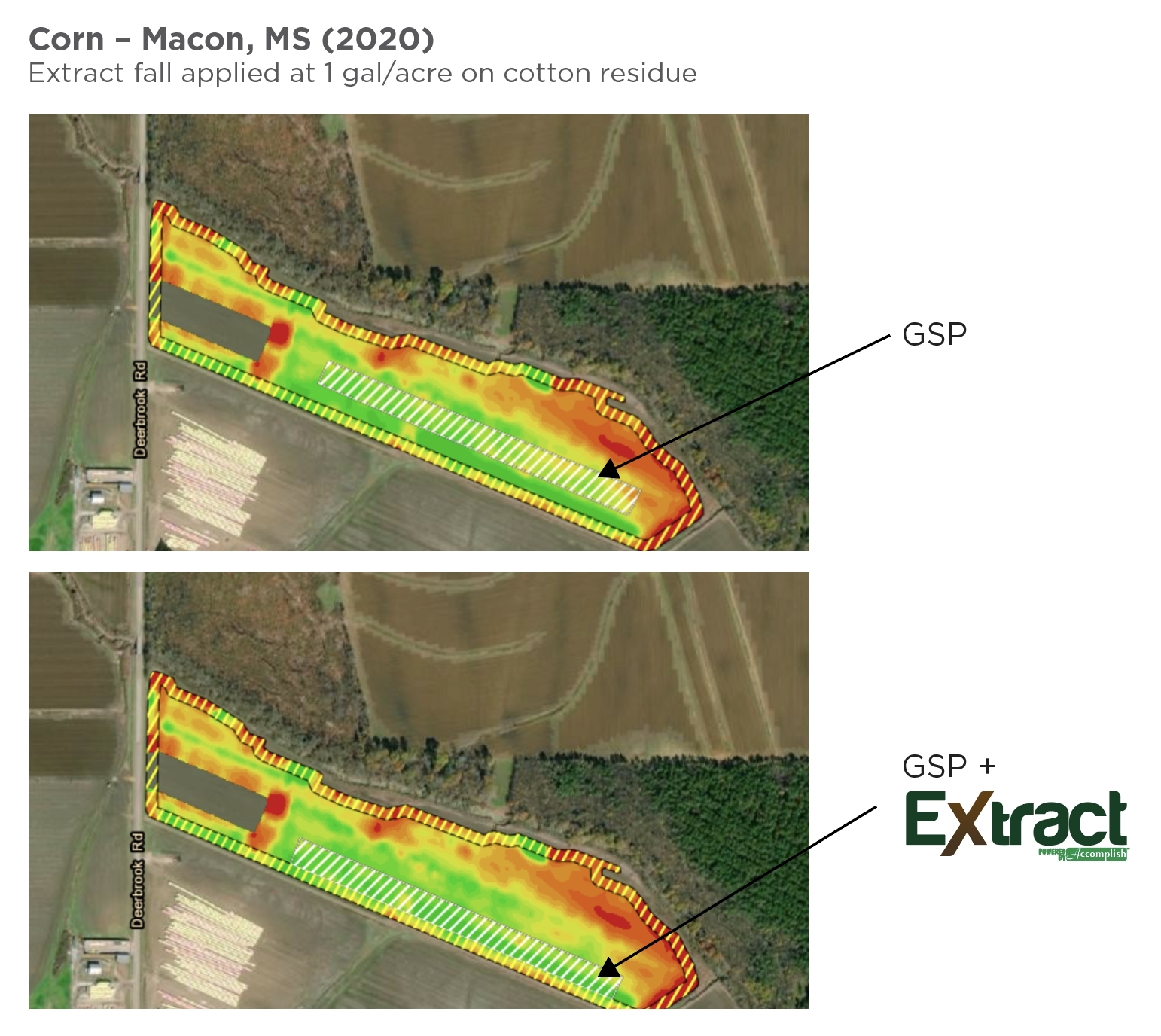

The NDVI shows the greater vegetation density and crop health where EXTRACT was applied on the cotton residue.

Extract PBA was applied in early October 2019 with 15 gallons of water per acre.

Extract PBA was applied in early October 2019 with 15 gallons of water per acre.

EXTRACT is a mineralization technology that converts organic nutrients into plant-available, inorganic forms that the plant can take up and use for nutrition. For example, an application of EXTRACT can help convert organic nitrogen into plant-available ammonium (NH4+) and convert organic phosphorus into plant-available hydrogen phosphate (HPO42-). In addition, potassium and micronutrients are mineralized and released back into the soil solution when EXTRACT is applied.

EXTRACT combines the concentrated biochemistry of ACCOMPLISH nutrient release technology with ammonium thiosulfate (ATS) to help growers easily and effectively manage nutrients tied up in the soil, in crop residues and in animal manures and poultry litters. The biochemistry in EXTRACT increases nutrient release and accelerates residue and manure/litter decomposition for rapid nutrient recycling, while ATS promotes an optimal carbon to nitrogen ratio to enhance soil microbial activity, further expediting nutrient return to the soil profile.

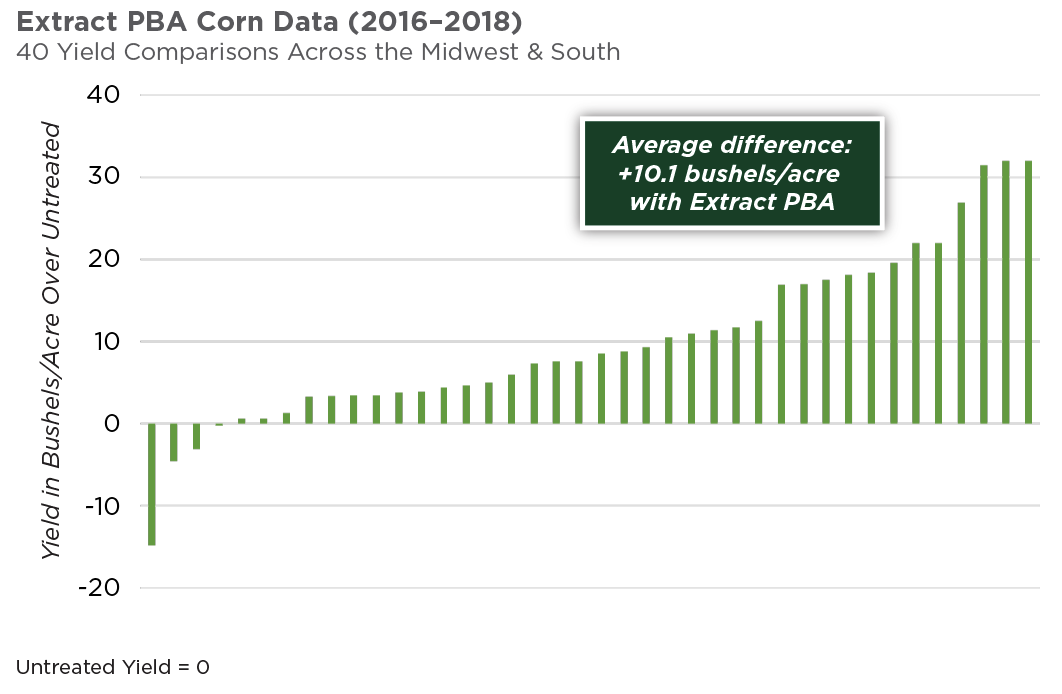

For growers, increased mineralization with EXTRACT can equate to greater nutrient availability for the next crop and an increase in crop yield.

Learn more about the mineralization technology in EXTRACT by downloading the Frequently Asked Questions booklet.

In the fall of 2017, Benjamin Rice, a crop consultant for

In the fall of 2017, Benjamin Rice, a crop consultant for

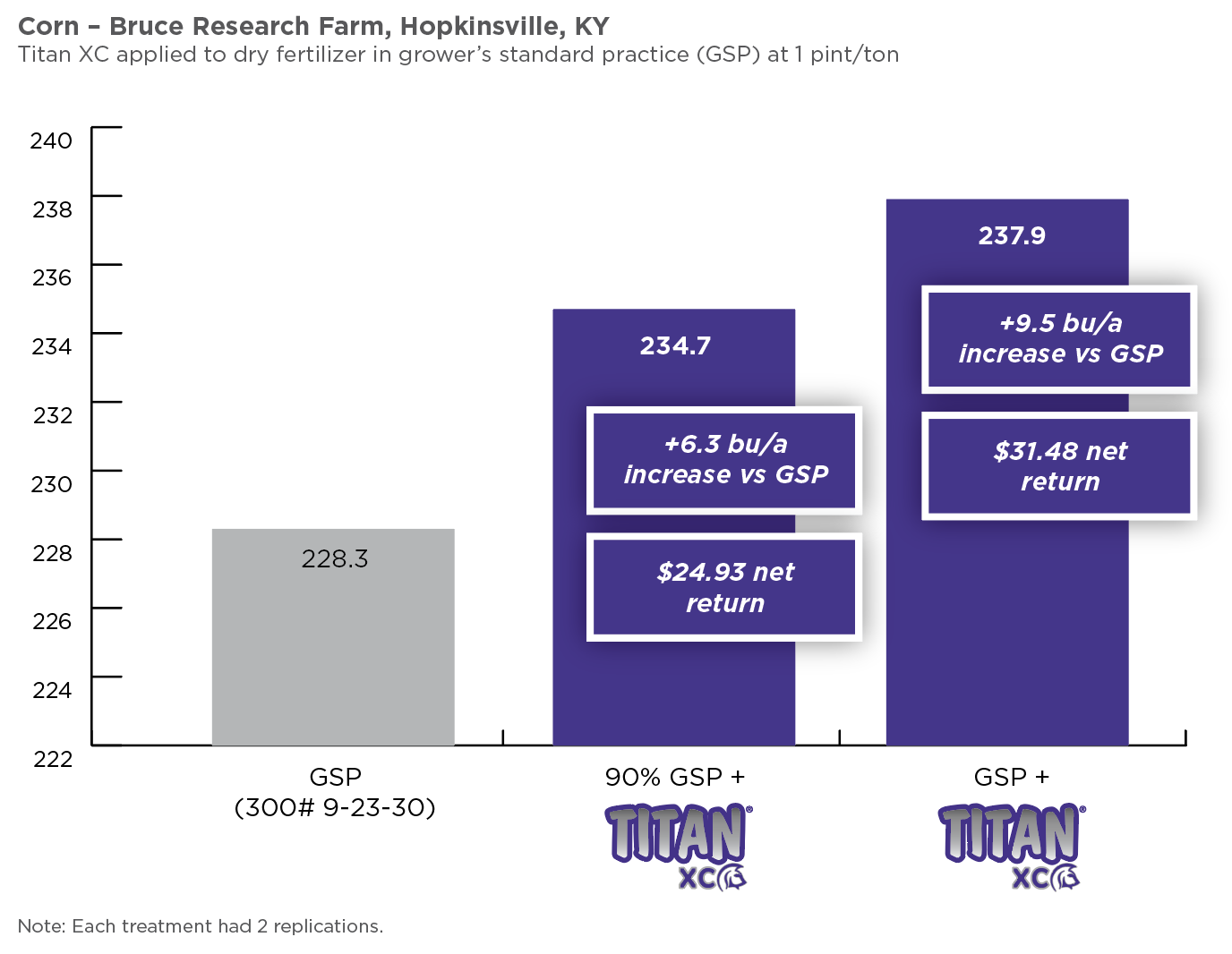

Luke Bryan makes a valid point when he sings, “rain makes corn,” but do you know what can help make even more corn?

Luke Bryan makes a valid point when he sings, “rain makes corn,” but do you know what can help make even more corn?