How high can corn yield go? In our short video, "Striving for Record Corn Yields," you'll see how some corn growers try to test the limits and push for record-setting yields.

"I wish I could tell you that high yield is a recipe, like following the cookbook. By gosh, it isn't that way. High yield...it is an art form," says Dr. Fred Below of the University of Illinois in the video.

The growers featured in the video faced multiple obstacles during filming in 2020 — from hurricanes and tropical storms in the East to a derecho that flattened crops and caused billions of dollars worth of damage across the Midwest.

"We had a tremendous crop out there. The storm just took part of it," says Iowa farmer Kelly Garrett, whose farm was in the path of the 2020 derecho that made records as the most destructive and costliest thunderstorm disaster in U.S. history.

"We had a hurricane come in here the other day. Raise a good corn crop and then it's sad to come in here and watch it laying on the ground the way it is, broke off," says Heath Cutrell, who farms in Virginia and North Carolina.

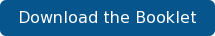

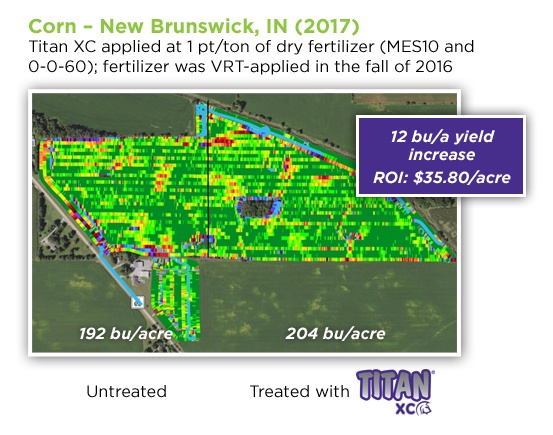

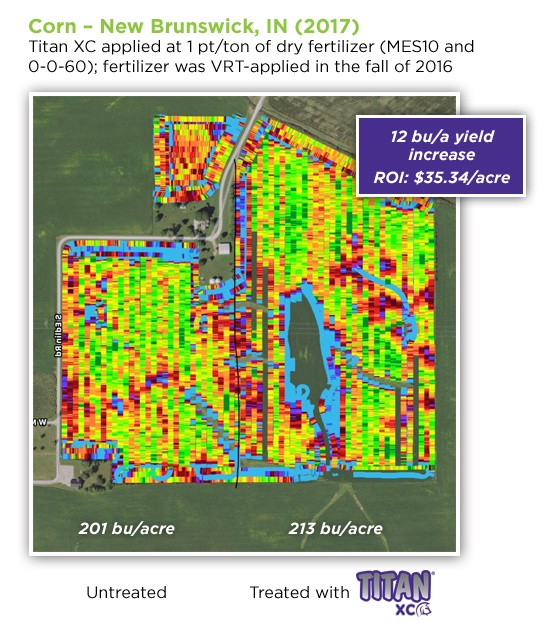

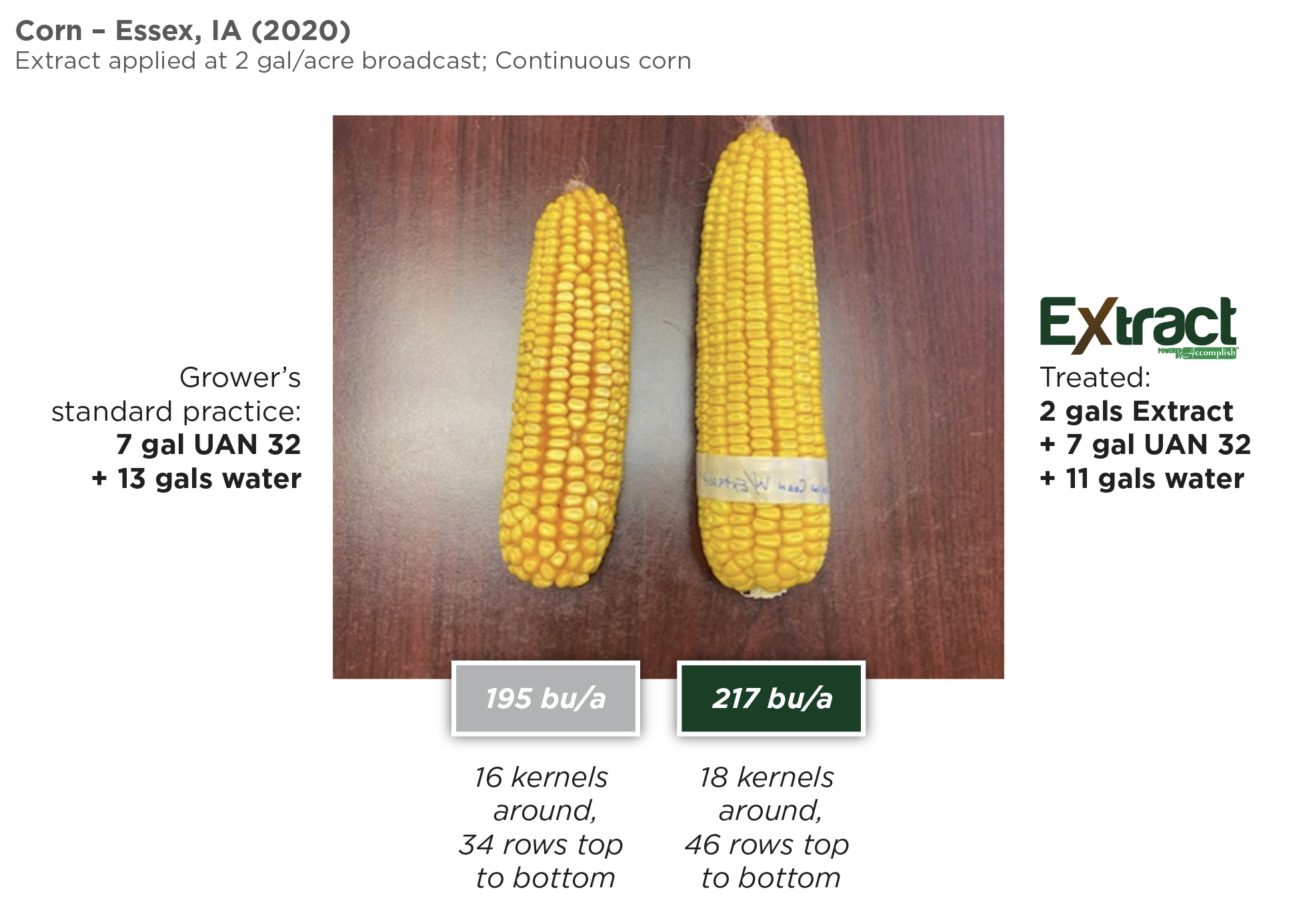

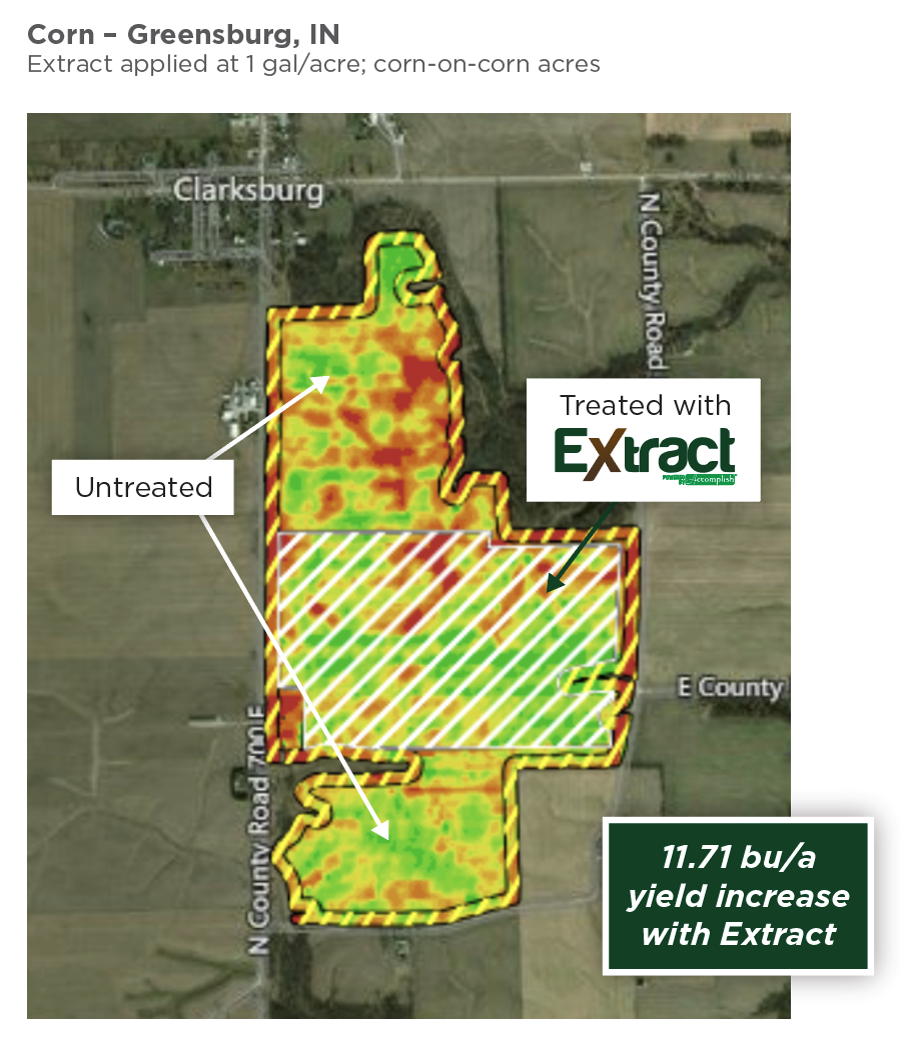

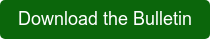

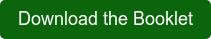

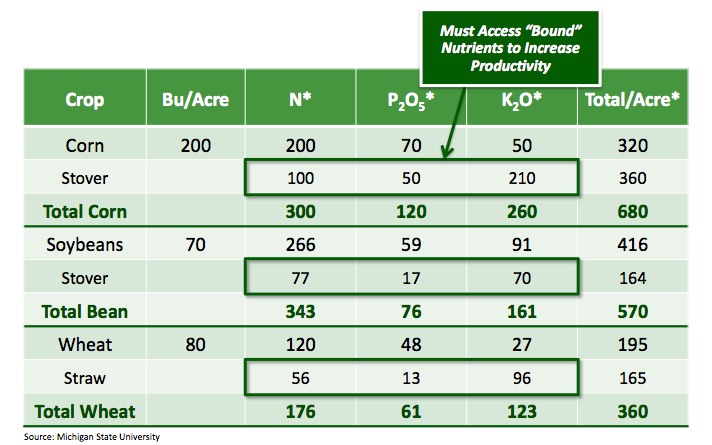

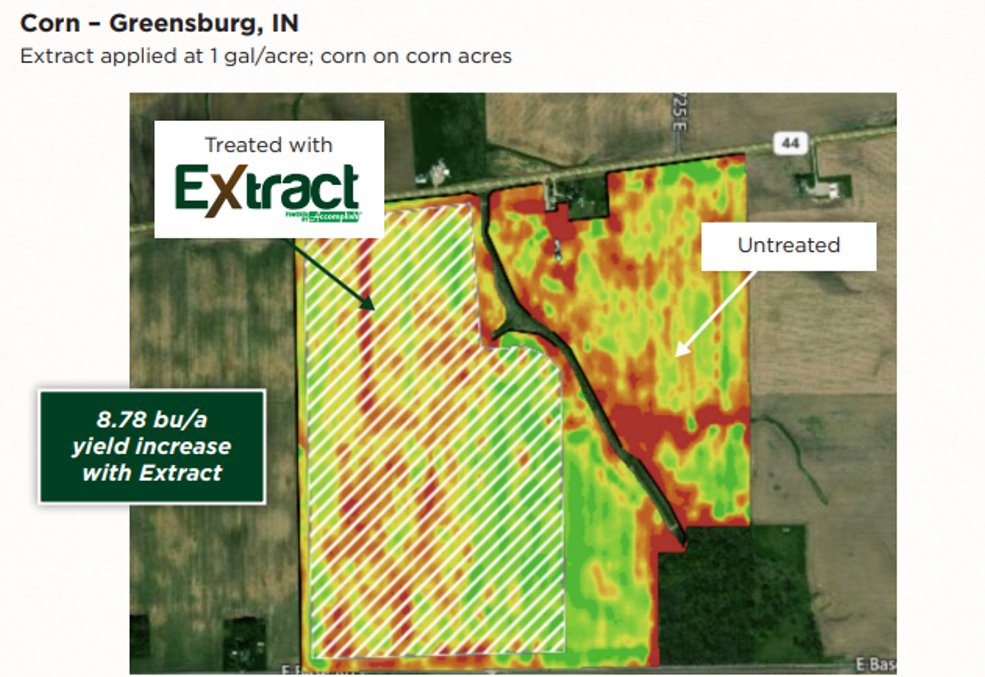

In addition to Kelly and Heath, the video features growers Don Stall (Michigan) and Kevin Kalb (Indiana). These farmers all have had winning entries in the NCGA Corn Yield Contest in recent years. Agricen's product technologies, including ACCOMPLISH, EXTRACT PBA and TITAN XC, have been part of their winning programs.

"You have to use products that work if you want to be chasing these kind of yields," says Kevin.

See their stories below.

You can also hear more from each grower by watching the full version of Last Stand, also available on our YouTube channel.

Don has been entering the NCGA Corn Yield Contest since 2003, when he noticed that he was already achieving yields comparable to the growers who were winning the contest. He has been the Michigan high yield champion for nine years in a row. In both 2017 and 2018,

Don has been entering the NCGA Corn Yield Contest since 2003, when he noticed that he was already achieving yields comparable to the growers who were winning the contest. He has been the Michigan high yield champion for nine years in a row. In both 2017 and 2018,  Kevin and Shawn have been entering the NCGA Corn Yield Contest since 2007, winning 12 national titles in the non-irrigated division. Both Kevin and Shawn have had

Kevin and Shawn have been entering the NCGA Corn Yield Contest since 2007, winning 12 national titles in the non-irrigated division. Both Kevin and Shawn have had

Our final

Our final