By Maud Hinchee, PhD, Chief Science Officer, Agricen Sciences

Plants are constantly responding to their senses. They can touch, smell, taste and otherwise sense water, food and predators—and they can remember. Of course, they don’t do all of this exactly the way a human does, but they do respond to the messages they receive from the world around them to survive, thrive and reproduce—much the way we do.

Plants are constantly responding to their senses. They can touch, smell, taste and otherwise sense water, food and predators—and they can remember. Of course, they don’t do all of this exactly the way a human does, but they do respond to the messages they receive from the world around them to survive, thrive and reproduce—much the way we do.

This is a pretty stimulating idea – that plants are actually sentient beings responding to stimuli in a purposeful manner and communicating with each other and with potential friends and foes. (For more on this, take a look at the “What Plants Talk About” episode from the PBS series, Nature.) It’s also an idea that has captivated researchers and companies in the agricultural space in recent years, most notably around the topic of biostimulants and other agricultural biologicals.

Biostimulants are any of a variety of naturally-derived products that signal plants through biochemical messages to improve their growth, health and nutritional value. Biostimulant products include humic and fulvic acids, seaweed extracts, protein hydrolysates, amino acids, microbial inoculants and biochemical products like Agricen’s, which are derived from naturally occurring microbial communities.

Typically, such products are organically complex, and we haven’t always immediately understood the way they work to influence plant growth and health. What we do know, however, is that they can have a positive effect on plants in the agricultural setting, a claim that is supported by significant and growing scientific evidence.

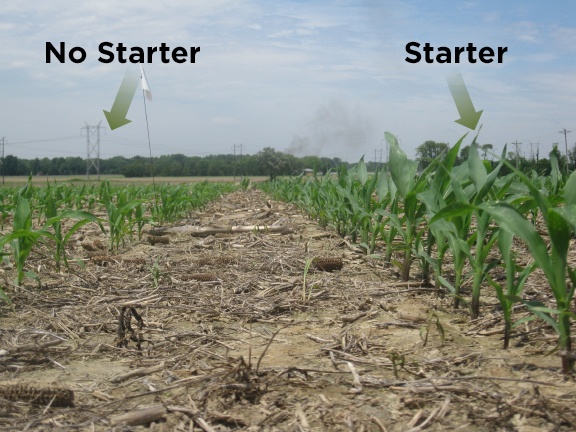

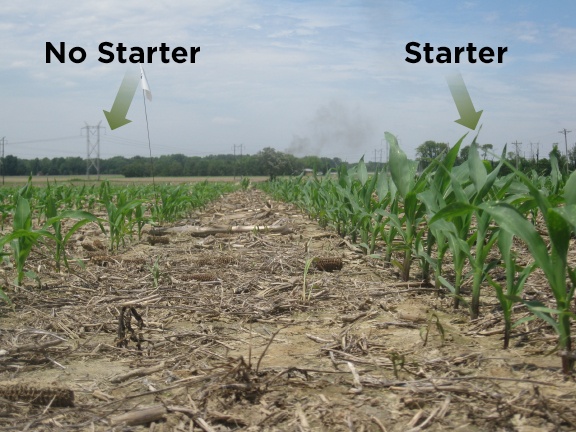

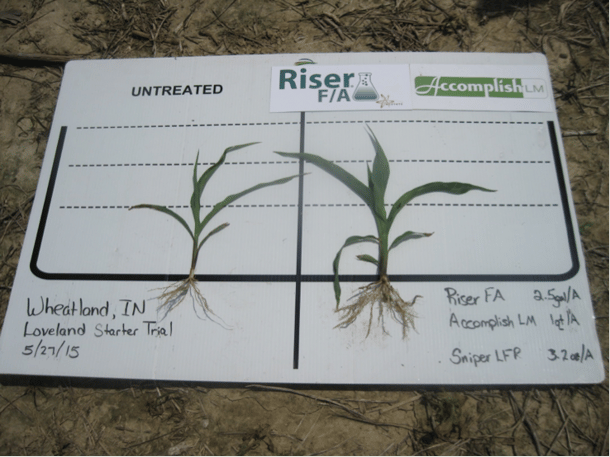

Biostimulants affect a variety of physiological and biochemical pathways in plants – influencing changes in plant behaviors such as increasing root growth, enhancing nutrient uptake and improving stress tolerance. Essentially, they provide a way to communicate with plants and “tip them off” on how to positively adjust to the environmental and biotic challenges typical of agricultural systems.

We are just beginning to comprehend the significant potential of these products. It will continue to be both exciting and challenging to explore the possibilities biostimulants offer as we work to increase agricultural production for future generations.

Learn more about biological products for agriculture:

![Frequently Asked Questions About Extract PBA [New Booklet]](https://blog.agricen.com/hubfs/Extract_FAQ_Image.jpg)

Plants are constantly responding to their senses. They can touch, smell, taste and otherwise sense water, food and predators—and they can remember. Of course, they don’t do all of this exactly the way a human does, but they do respond to the messages they receive from the world around them to survive, thrive and reproduce—much the way we do.

Plants are constantly responding to their senses. They can touch, smell, taste and otherwise sense water, food and predators—and they can remember. Of course, they don’t do all of this exactly the way a human does, but they do respond to the messages they receive from the world around them to survive, thrive and reproduce—much the way we do.

![[Video] Grower Stories: Brandon Burkhart, Iowa Corn & Soybean Farmer](https://embed-ssl.wistia.com/deliveries/11d6f78c55f64a1eb431edb32af22546b27b2525.jpg?image_play_button=true&image_play_button_color=74a0bce0&image_crop_resized=440x248)

Brandon Burkhart is a fourth-generation farmer from Oto, Iowa. Varying soils on his family's 2500-acre corn and soybean operation used to mean it was difficult to get a good, efficient use out of their applied nutrients. Today, Brandon and his family use ACCOMPLISH

Brandon Burkhart is a fourth-generation farmer from Oto, Iowa. Varying soils on his family's 2500-acre corn and soybean operation used to mean it was difficult to get a good, efficient use out of their applied nutrients. Today, Brandon and his family use ACCOMPLISH![[Video] How to Use This Season’s Residue to Feed Next Season’s Crop](https://embed-ssl.wistia.com/deliveries/150509fe57db88b4dc437a87068ca5a254c0e74c.jpg?image_play_button=true&image_play_button_color=71b871e0&image_crop_resized=440x248)