By Stephen Sexton, Director of Technical Sales (@AgricenLifer), Agricen

This season, with high corn yields and a late harvest in many places, it will be critical to take steps to maximize residue decomposition and nutrient release for the benefit of next seasons’ crops. It’s important to keep in mind that the primary limiting factor for residue decomposition is cooler temperatures, which reduce the microbial activity required for residue breakdown. Given the late harvest, that means there's only been a short window for natural decomposition processes to take place. In addition, larger yields produce more residue, which requires more time and energy to properly break down.

We’ve previously discussed just how inefficient applied NPK fertilizers can be in the first year after application, a problem that is compounded in high-residue fields.

Corn residue from a 200 bushel crop contains approximately 116 units of nitrogen (N), 27 units of phosphorous (P) and 209 units of potassium (K). Nutrients in the residue are not in a plant-available form, and mineralization must occur prior to plant utilization. Meanwhile, as soil microbes digest crop residues, they can tie up applied N, making it unavailable for plant growth in the spring. In corn, the lack of N causes corn seedlings (emergence to V3-V4) to turn yellow, also known as “ugly corn syndrome.”

To increase the efficiency of their applied fertilizer in high-residue conditions, many growers are now using Accomplish LM (a biochemical fertilizer catalyst that is not dependent on soil microbial activity) in their nutrient release programs—and are seeing higher yields as a result. Applied in the fall (preferably) or even along with a grower’s standard spring N application, Accomplish LM hastens residue decomposition and mineralization of applied nutrients. This practice is supported by data that includes the findings from a large corn trial conducted in five Northeast Iowa locations in 2010 and 2011.

Iowa Corn Trial: More Nutrient Availability and Uptake, Higher Yields with Accomplish LM

The trial examined the effects of using additional spring-applied N or Accomplish LM (which does not contain N) to address ugly corn syndrome. Four different N sources were used*, and were applied at 40 units of N per acre in late March, 30 days prior to planting. The Accomplish LM treatment was applied at 3 pints per acre with water and no additional N. These applications were in addition to the grower’s standard N application (200 units of N as anhydrous ammonia [NH3]) that had been applied in the fall.

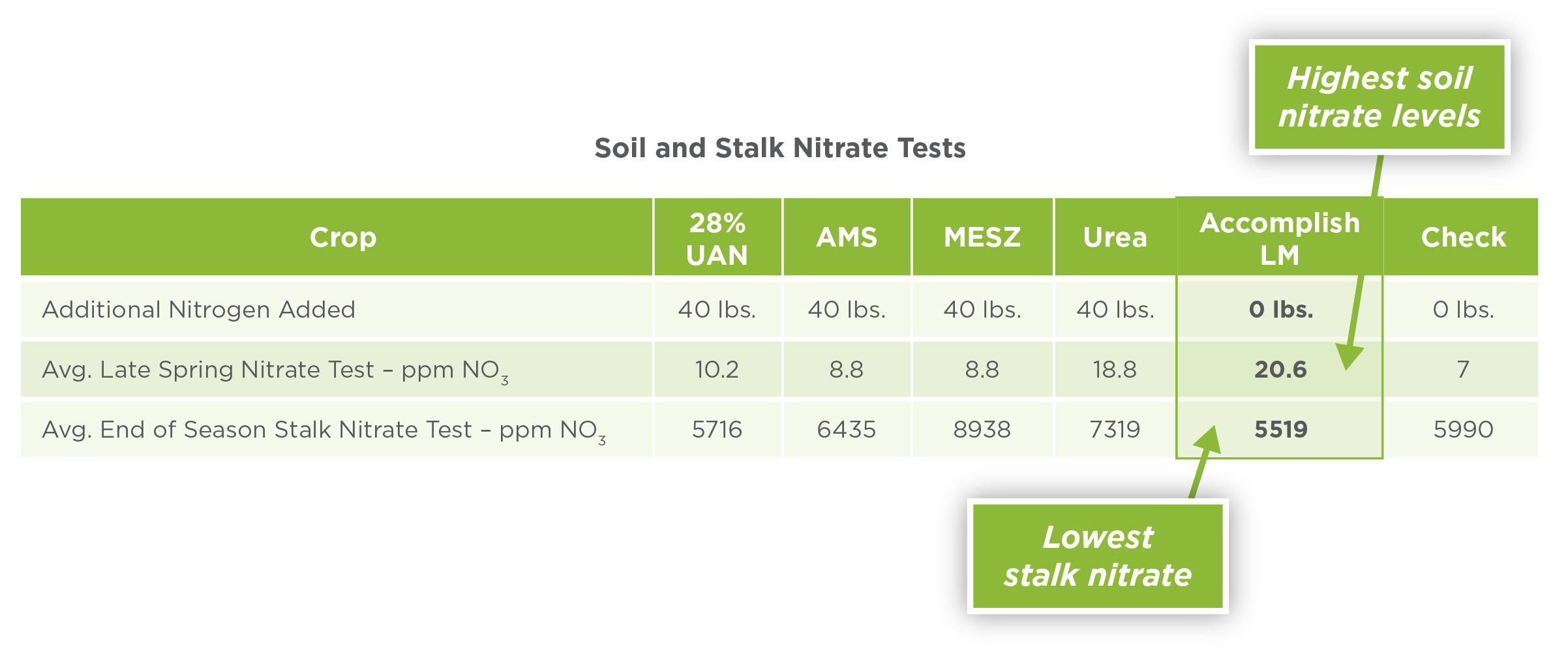

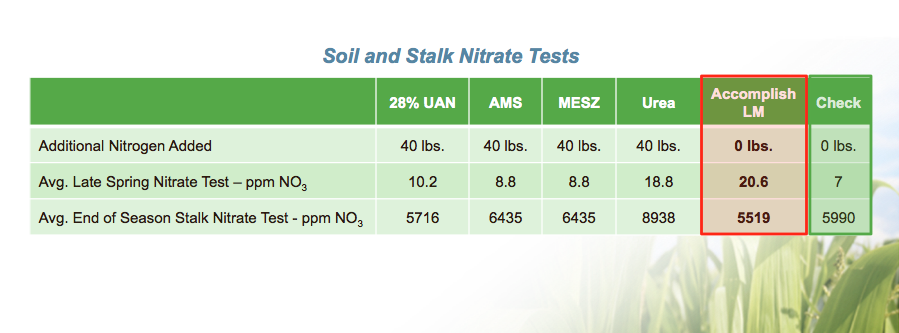

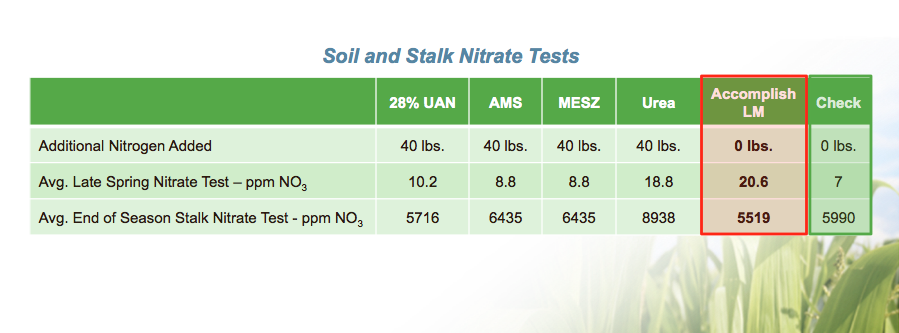

Soil nitrate levels were recorded for each treatment 60 days after planting, and stalk nitrate levels were taken after harvest. The soil nitrate concentration of Accomplish LM (20.6 ppm) was almost three times that of the grower standard (7 ppm). In addition, the Accomplish LM treatment was associated with the lowest stalk nitrate reading of all the treatments (Table 1).

Those two data points, coupled with the Accomplish LM treatment having the highest yield, tell a compelling story that the application of Accomplish LM on the residue created more available N (higher soil nitrate) than applying 40 additional units of N–resulting in improved mineralization of nutrients–and that it delivered that N to the grain (lower stalk nitrate and higher yield).

Table 1. By late spring, Accomplish LM increased soil N availability without additional N application.

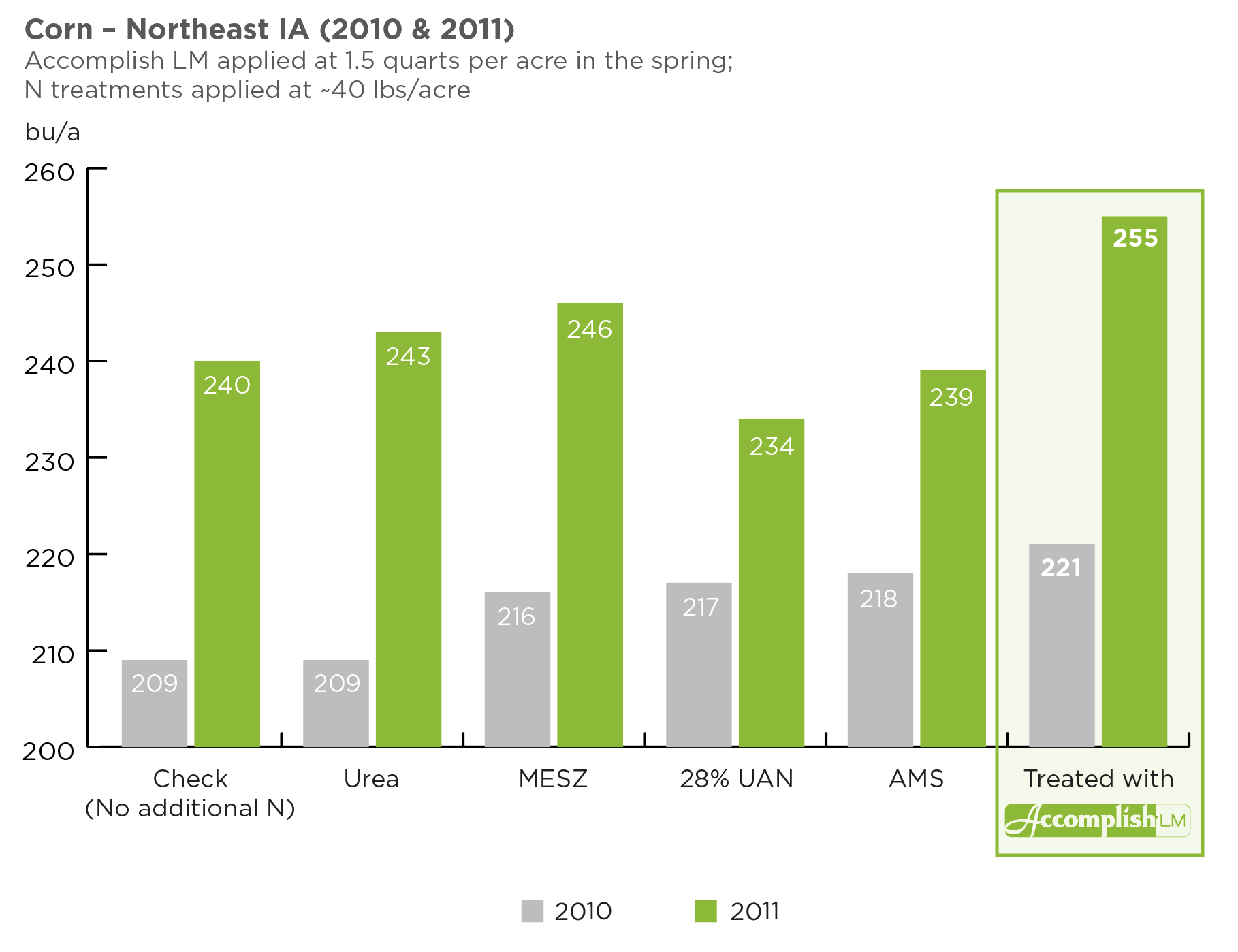

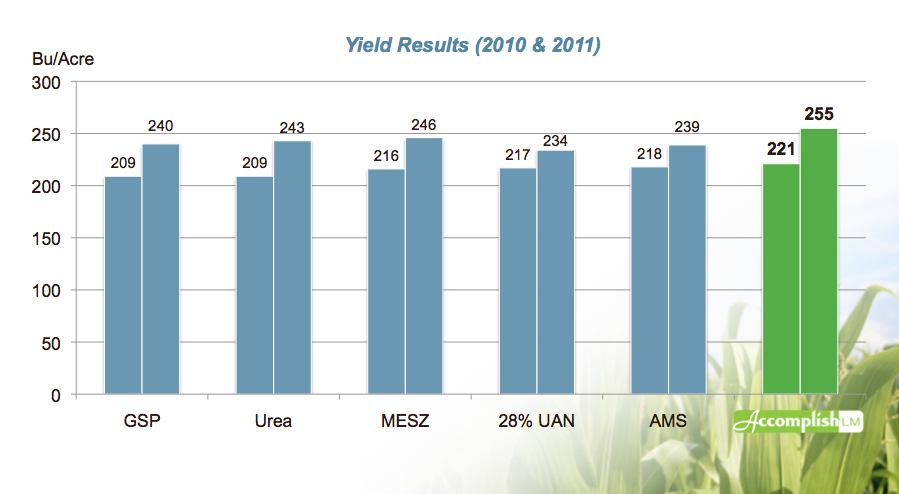

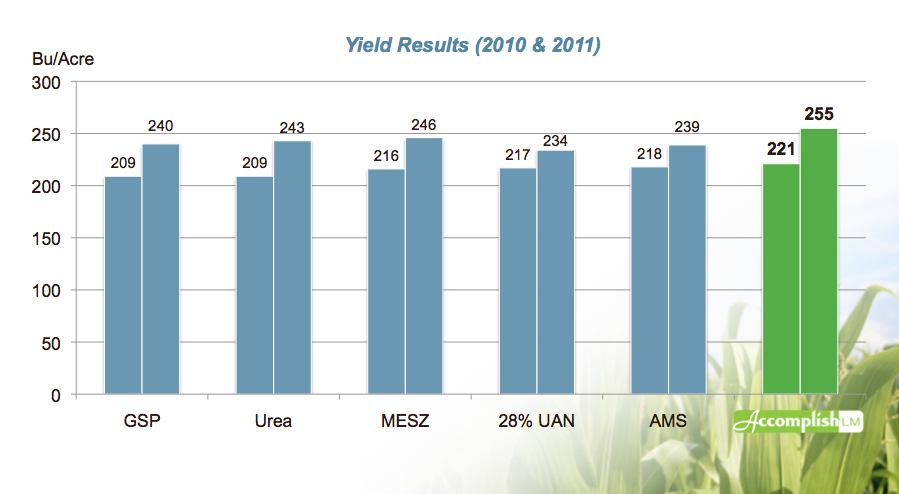

In 2010, Accomplish LM had the highest yield (221 bushels per acre) over all treatments, with an 12 bushel per acre increase compared to the check (Figure 1). In 2011, Accomplish LM again had the highest yield (255 bushels per acre, a 15 bushel/acre increase vs. check). Moreover, while nitrogen use efficiency (units of N/yield in bushels) was not improved for the additive fertilizer applications versus grower standard (0.96 units N/bushel in 2010 and 0.83 units in 2011), it was increased with Accomplish LM (0.90 units N/bushel in 2010 and 0.78 units in 2011).

Figure 1. Corn yield results in 2010 (left bars) and 2011 (right bars). Accomplish LM was associated with the highest average yields in both years. The grower’s standard practice was 200 units of N as fall-applied NH3. Accomplish LM was applied at 1.5 quarts/acre. Abbreviations: GSP, grower’s standard practice; MESZ, MicroEssentials® SZ (Mosaic Company); UAN, urea ammonium nitrate; AMS, ammonium sulfate.

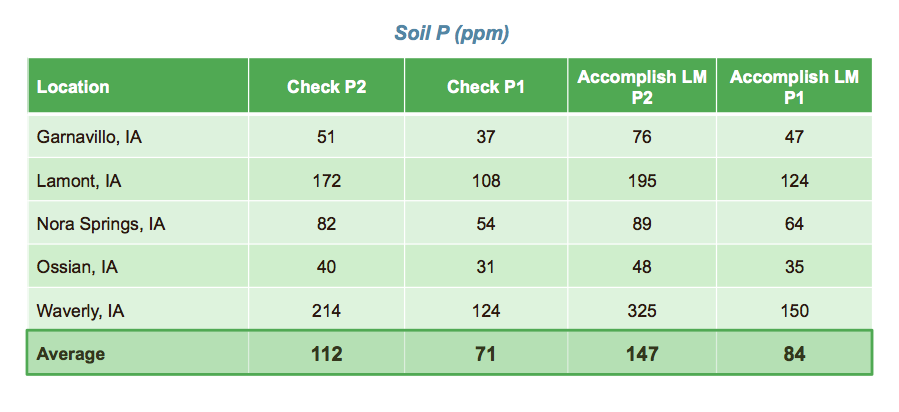

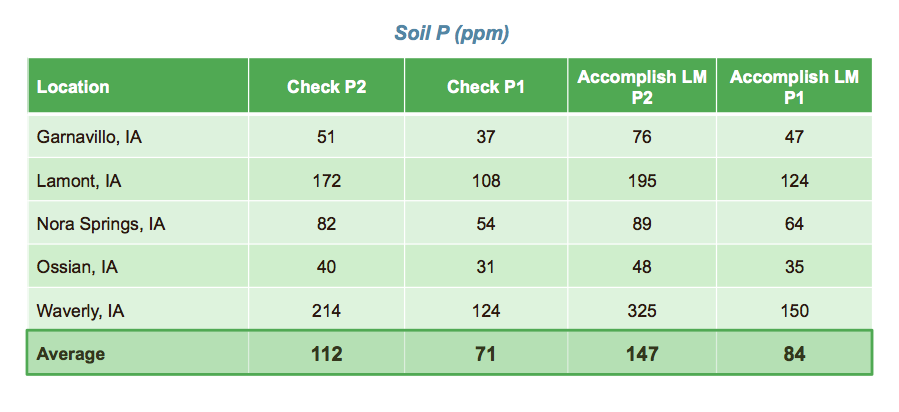

In 2011, soil phosphorous levels (P1 & P2) were examined (Table 2).

Table 2. Improved P availability when Accomplish LM is combined with a standard fertility program.

Just 60 days after application, all of the Accomplish LM treated blocks showed increased soil phosphorous levels. On average, P1 levels increased by 18% and P2 levels by 31% compared to the check. It requires 8-10 pounds of P2O5 to raise a P1 soil analysis 1 ppm; a 13 ppm increase, which was achieved with the Accomplish LM treatment, is equal to applying 100 - 130 lbs of P2O5.

To summarize, Accomplish LM can be used to help mineralize and release nutrients in high residue fields. Over all five Iowa locations, adding just three pints of this biochemical additive 30 days prior to spring planting increased the efficiencies of soil N and soil P, resulting in the highest overall corn yields both years.

* The four N sources were: urea ammonium nitrate (UAN), 28-0-0; ammonium sulfate (AMS), 21-0-0-24S; MicroEssentials® SZ (MESZ), 12-40-0-10(S)-1(Zn) (Mosaic Company); urea, 46-0-0.

**The recommended Accomplish LM residue treatment application is: Accomplish LM at 2 quarts/acre (+1-2 gallons of 28% or 32% UAN + 8.5 gallons of water).

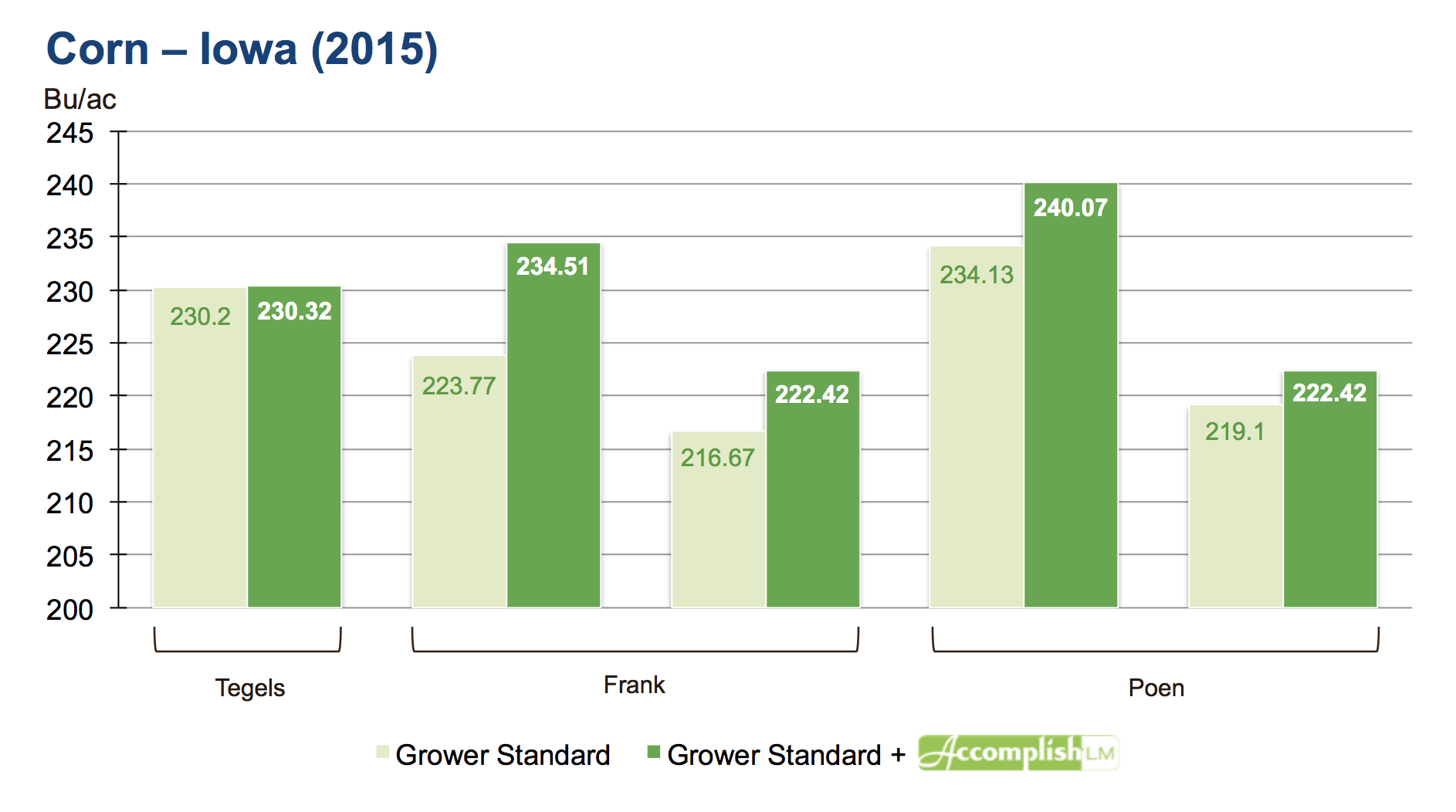

Jeff Frank, a fourth generation farmer from Auburn, Iowa, grows corn and soybeans on a 1,200-acre century farm that he and his wife operate. He is an avid drone enthusiast and dealer (hear him speak more about drones and farming in

Jeff Frank, a fourth generation farmer from Auburn, Iowa, grows corn and soybeans on a 1,200-acre century farm that he and his wife operate. He is an avid drone enthusiast and dealer (hear him speak more about drones and farming in

![[Video] Grower Stories: Brandon Burkhart, Iowa Corn & Soybean Farmer](https://embed-ssl.wistia.com/deliveries/11d6f78c55f64a1eb431edb32af22546b27b2525.jpg?image_play_button=true&image_play_button_color=74a0bce0&image_crop_resized=440x248)

Brandon Burkhart is a fourth-generation farmer from Oto, Iowa. Varying soils on his family's 2500-acre corn and soybean operation used to mean it was difficult to get a good, efficient use out of their applied nutrients. Today, Brandon and his family use ACCOMPLISH

Brandon Burkhart is a fourth-generation farmer from Oto, Iowa. Varying soils on his family's 2500-acre corn and soybean operation used to mean it was difficult to get a good, efficient use out of their applied nutrients. Today, Brandon and his family use ACCOMPLISH

In continuous no-till corn, crop residues with a high carbon-to-nitrogen (C:N) ratio (about 60:1) can build up. When this happens, the soil microorganisms responsible for decomposing crop residue compete with the plant for nitrogen. A C:N ratio of 30:1 or lower is required for the soil microorganisms to effectively decompose crop residues without immobilizing the soil nitrogen needed by the growing plants.

In continuous no-till corn, crop residues with a high carbon-to-nitrogen (C:N) ratio (about 60:1) can build up. When this happens, the soil microorganisms responsible for decomposing crop residue compete with the plant for nitrogen. A C:N ratio of 30:1 or lower is required for the soil microorganisms to effectively decompose crop residues without immobilizing the soil nitrogen needed by the growing plants.