By Brian Cornelious, PhD, Agricen

The use of starter fertilizer, aimed at getting plant nutrients in a concentrated zone close to the point of seed placement, is a common practice in some parts of the country.

A standard starter program for corn in the U.S. Corn Belt is 3-5 gallons of ammonium polyphosphate (10-34-0) plus 1 quart of zinc per acre. More progressive growers have gravitated towards readily available orthosphosphate blends containing micronutrients or other enhancements like biostimulants. Regardless of the rate, timing, source and amount (the “4Rs”) of the practice, the goal is the same: Get the most out of every nutrient applied for better early growth and development.

Conversion from polyphosphate to plant-available orthophosphate takes place in the soil, where microbes and soil chemistry both play a role in making the applied and existing soil nutrients available to the plant, as well as in the timing of nutrient release into the soil solution. For any liquid starter program to be successful, growers must consider several key factors like soil test values, crop yield goals, field conditions and potential for nutrient release when the crop needs them most.

Thankfully, growers don’t have to leave it all up to nature. By enhancing liquid starter programs with ACCOMPLISH MAX or PROLOGUE, growers can speed up the conversion process in the soil and facilitate plant nutrient uptake by providing highly available forms of nutrients. The outcome is improved plant performance, as demonstrated in the trials below.

ACCOMPLISH MAX

ACCOMPLISH MAX is specifically formulated for use with liquid starter fertilizers. It contains diverse biochemicals (e.g., organic acids, enzymes) that interact with liquid fertilizers and soil chemistry to improve nutrient availability and facilitate nutrient uptake by the crop. It also contains a kelp-based technology that helps crops better tolerate potentially yield-robbing stresses like cold temperatures, saline soil, heat or dry conditions.

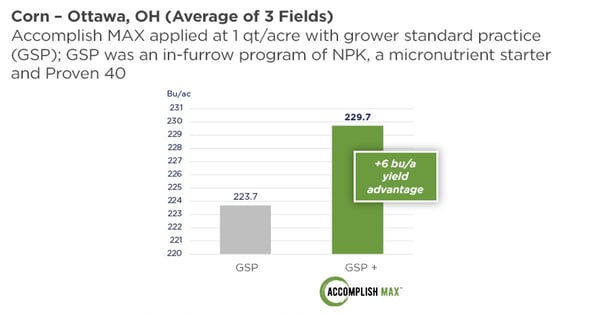

In the corn trial below from Ohio, the grower standard practice (GSP) was an in-furrow program consisting of NPK, a micronutrient starter and Proven 40 (a microbial nitrogen-fixing product from Pivot Bio). This was compared to GSP plus 1 quart/acre of ACCOMPLISH MAX over three fields.

The results? Adding ACCOMPLISH MAX to the grower's standard in-furrow program led to a yield advantage of +6 bu/acre over the GSP alone.

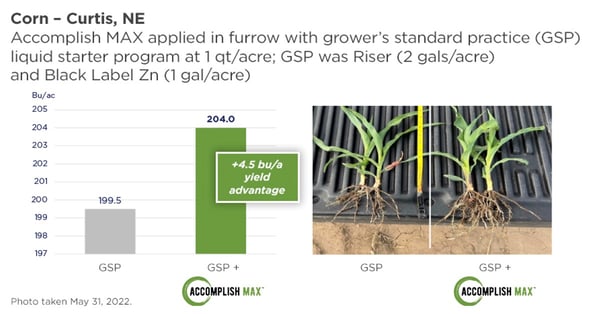

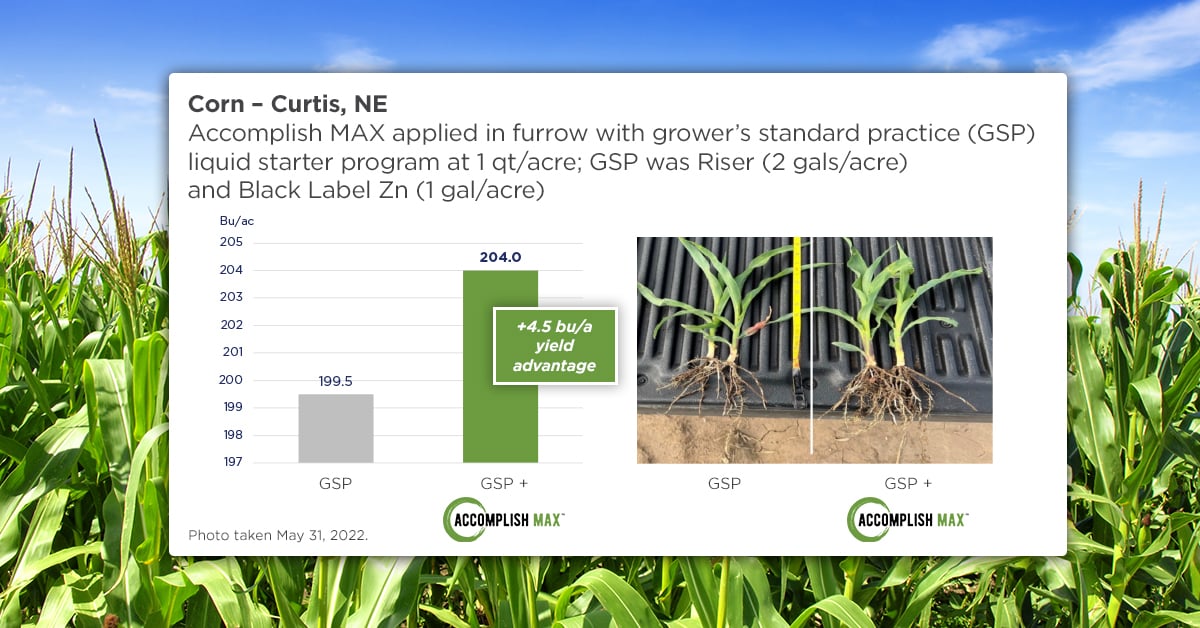

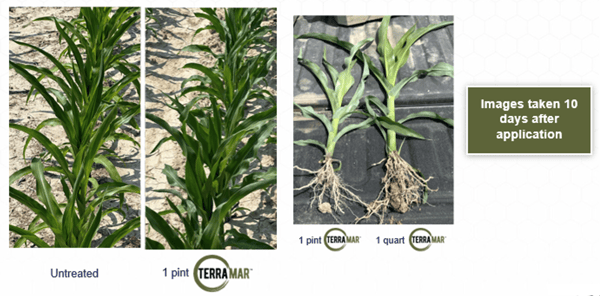

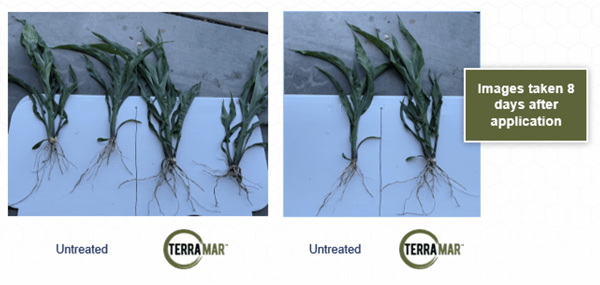

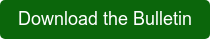

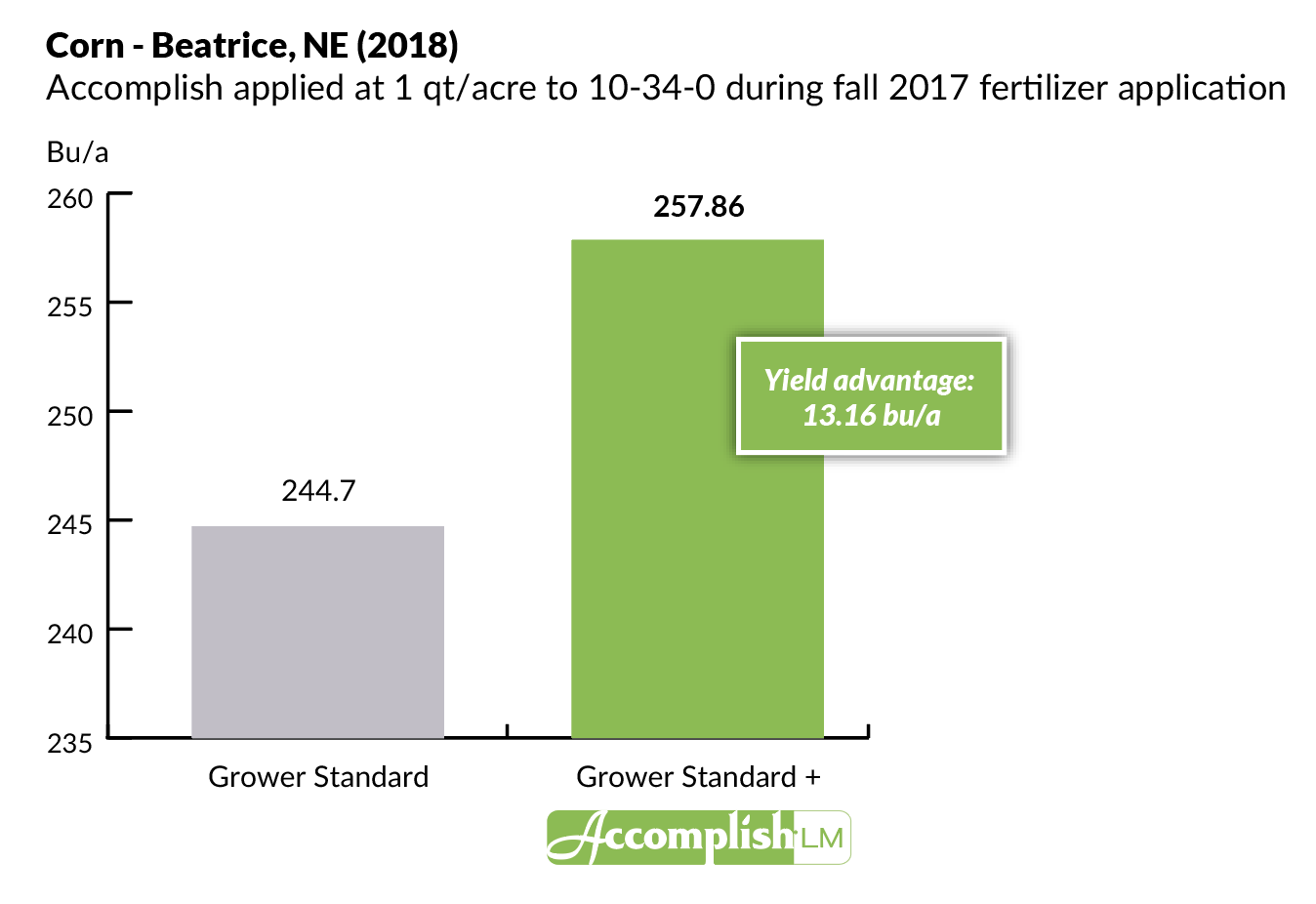

In another example, a corn trial in Nebraska looked at the impact of adding ACCOMPLISH MAX at 1 quart/acre to a starter program consisting of Loveland Products’ Riser (2 gals/acre) and Black Label Zn (1 gal/acre).

The results? A visual difference with ACCOMPLISH MAX earlier in the season, including thicker stalks and healthier plants above ground, with deeper, more developed roots below. The early, healthier start resulted in a +4.5 bu/acre yield advantage at harvest compared to the starter program that did not include this technology.

PROLOGUE

PROLOGUE (5-0-0 6.3% Zn) is a combination of highly plant available zinc and nutrient solubilizing technology comprised of microbial metabolites (biochemicals) and active, phosphorus-scavenging microbes that colonize within the root system.

PROLOGUE fits any banded liquid phosphorus-based fertilizer program requiring supplemental zinc for optimal plant growth. It is formulated to increase the efficiency of both applied phosphate and existing phosphate bound in the soil, as well as balance the P:Zn uptake ratio. (For every 10 units of phosphorus, a plant needs 1 unit of zinc.)

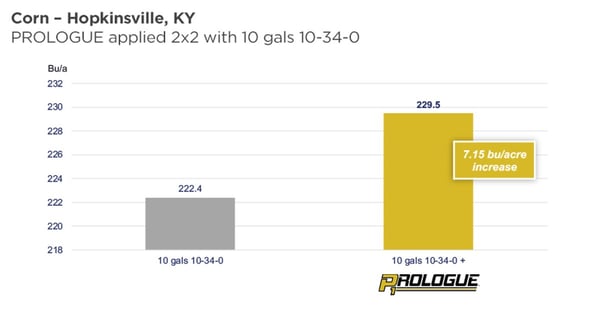

In this corn trial from Kentucky, PROLOGUE was applied 2x2 with 10 gals/acre of 10-34-0.

The results? A yield advantage of +7.15 bu/acre with PROLOGUE in the starter program compared to the 10-34-0 starter alone.

Crops that get off to a good start often maintain an advantage during the growing season over those that struggle to get going. As these studies show, growers that include a technology such as ACCOMPLISH MAX or PROLOGUE in their starter programs—whether a polyphosphate, an orthophosphate/polyphosphate blend or other liquid starter—can maximize the efficiency of applied nutrients and improve crop performance.

Learn more about starter fertilizer programs by downloading our booklet, Improving Crop Yields with Starter Fertilizers.

Many agricultural areas across the United States are facing weather-related challenges, but there are still opportunities to make the most

Many agricultural areas across the United States are facing weather-related challenges, but there are still opportunities to make the most

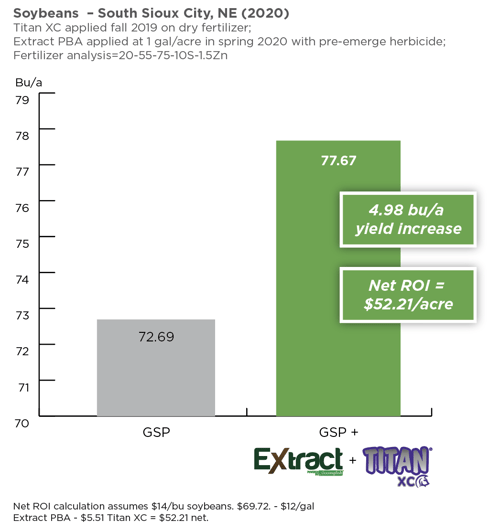

![[Trial] Titan XC Provides 14 Bushel Yield Advantage in Soybeans](https://blog.agricen.com/hubfs/TitanXC-soybeans.jpg)