The soil is a living environment, full of microorganisms that create biochemical compounds that influence plant growth. At Agricen, we take this biochemistry and make it work even better for the grower, with benefits that include improved plant performance and increased nutrient availability.

In this short video, Agricen’s Director of Applied Sciences, Dr. Brian Cornelious, explains how the biochemistry in Accomplish LM and Titan PBA works to make the difference between having a good growing season and having a great growing season.

Dr. Brian Cornelious: Everybody knows where our food comes from. It’s right here on the farm. But do we really understand what it takes for a grower to get the most out of every acre he plants? In the next couple of minutes, I’m going to show you how a grower can use the biochemistry in Accomplish LM and Titan PBA to feed our growing population.

[Onscreen: “Agricen. Based on Nature Built on Science.” Then: “The Science Behind It All”]

Brian: The soil is a living environment, full of organisms producing biochemical compounds that influence plant growth. I’m holding just a couple grams of soil. Each gram of soil contains as many as 1 billion bacteria. At Agricen, we have a team of scientists working to make this biochemistry work even better for the grower.

[Onscreen: “The Lab: Where It All Starts”]

Brian: We’re here in the lab, and this is where we really get to understand how the biochemistry in Accomplish LM and Titan PBA actually help to improve our plant performance and increase our nutrient availability.

So, there are key nutrients we’re going to talk about today: nitrogen, phosphorous and potassium.

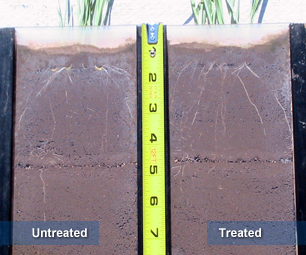

For nitrogen – the most abundant gas in the atmosphere – we have to have nitrogen to breathe; plants have to have nitrogen to grow. If you want that dark green color, add more nitrogen to the plant. Nitrogen, for the most part in the soil profile, is organic. We have to convert organic nitrogen—which is crop residues, manures, litters, composts, any of those organic sources—into ammonium or nitrate or inorganic forms the plant can use. It’s called the mineralization process. Biochemistry is the only thing in the soil profile that actually helps to mineralize organic nitrogen into an inorganic form that the plants can use.

What about phosphorous? If you really want to get that plant going, it’s just like lighting a match. We have to have red phosphate on that match to get that thing going. The phosphorous in the plant really helps with the establishment and getting that plant going and off to a good start. Again, we’re dealing with mineralization. Lots of phosphorous in the soil profile is inorganic. We have to get it into H2PO4 or HPO4, plant available forms of phosphorous.

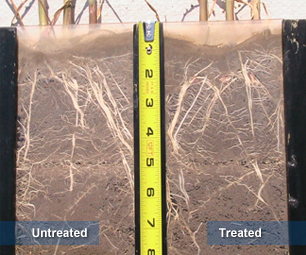

What about potassium? Now, you’re probably familiar with this. If you eat bananas, you’re consuming potassium. Potassium helps the plant with regulation of water through the plant. You have to have potassium. It’s a little bit different from nitrogen and phosphorous. We’re not talking about mineralization of organic nutrients. We’re talking about release of nutrients that are in the profile. It gets locked in between the soil layers and it’s not available to the plant. The biochemistry in Accomplish LM can actually help improve that soil structure that helps improve that plant’s ability to take up that potassium.

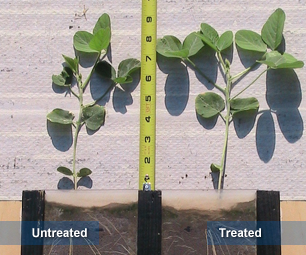

There’s one more way that Accomplish LM and Titan PBA work to improve crop growth. Titan and Accomplish make the underground transportation system of nutrients much more efficient. It’s the difference between this [Points to slow traffic] and this [Traffic speeds up].

[Onscreen: “Dr. Pepper Ballpark: Home of the Frisco Rough Riders”]

Brian: To further explain the benefits of adding the biochemistry in Accomplish LM and Titan PBA to a grower’s fertility program, we’re here at the ballpark. So, let’s play ball.

The initial fertilizer application – that puts us at home plate. There’s several things that have to happen in order for us to score that run. First, the soil temperatures have to increase. That gets us to first base.

After those temperatures increase, microbes start to function. They’re producing biochemistry now. That gets us to second base. There’s something important about second base in a game of baseball. That’s having a runner in scoring position. With the biochemistry in Accomplish LM and Titan PBA, we start at second base.

Brian: Once the biochemistry helps to mineralize the nutrients, that gets us to third base. The plants are actually taking those nutrients up. Now the plants can actually utilize those nutrients for functioning and yield. And that scores that run. But, with the biochemistry in Accomplish LM and Titan, we’ve got that advantage. We’re scoring two runs with the same process.

As growers know, things are tight. Adding the biochemistry in Accomplish LM and Titan PBA can be the difference in just having a good season, and having a great season.

Brian: At Agricen, it’s important for us to deliver new technology options to allow the grower to get the most out of every acre he plants. The biochemistry in Accomplish LM and Titan PBA improve access of nutrients to the plant, more flow of nutrients in the plant, and also increases the efficiency of utilization of nutrients by the plant.

At Agricen, our technology truly is based on nature and built on science. I’m Brian Cornelious. Thank you for watching.

In this short video,

In this short video,