This spring, many growing areas of the United States are coming off an extended period of cooler-than-normal temperatures. This makes it an ideal time for post applications of TERRAMAR and RADIATE to get the crop back on track.

This spring, many growing areas of the United States are coming off an extended period of cooler-than-normal temperatures. This makes it an ideal time for post applications of TERRAMAR and RADIATE to get the crop back on track.

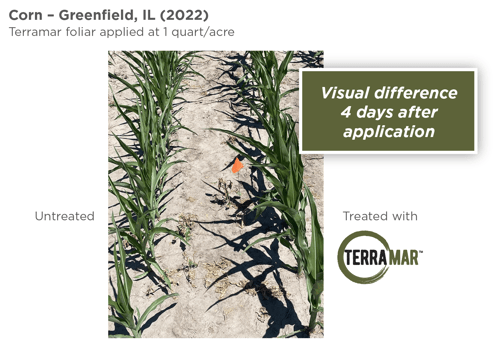

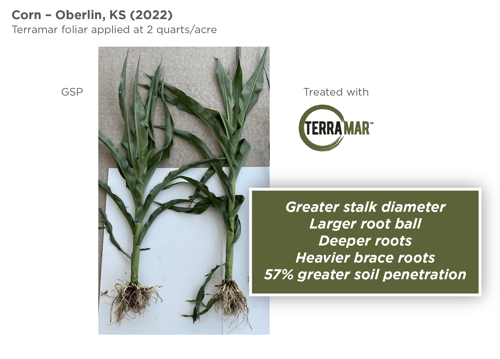

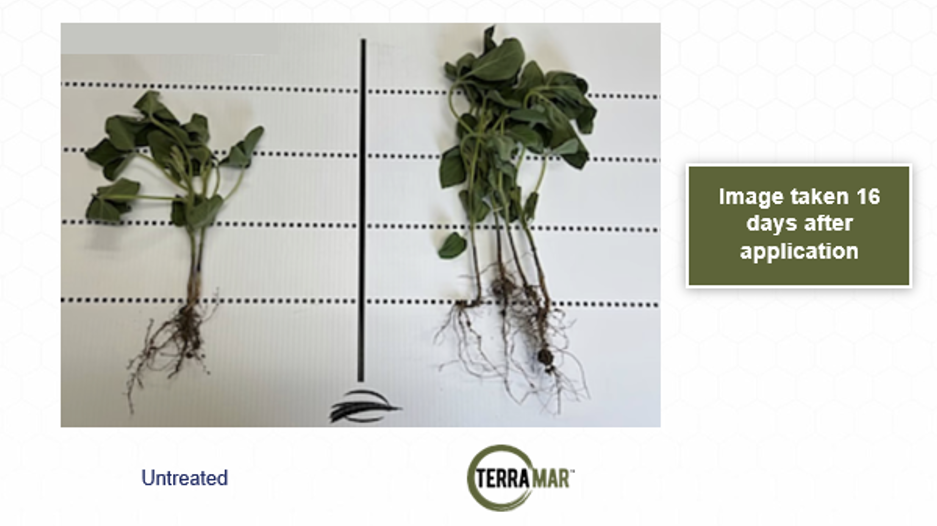

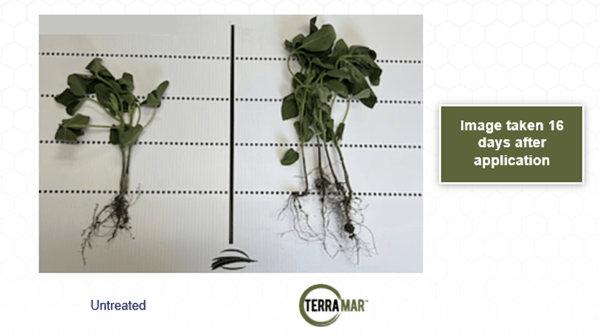

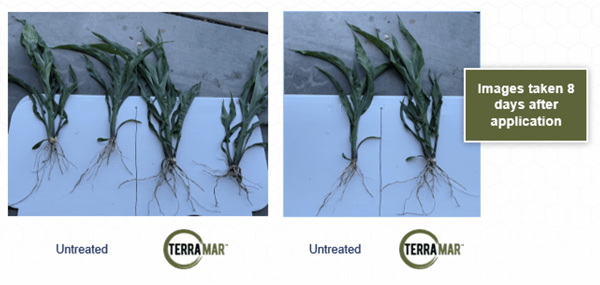

Cooler conditions slow plant photosynthesis and physiological functions, which leads to slower crop growth and development. TERRAMAR helps in this scenario because it increases the rate of photosynthesis, chlorophyll production and water transpiration, leading to increased nutrient levels in the plant. RADIATE is also useful here, since RADIATE enhances root development, increasing the plant's ability to access nutrients and moisture.

TERRAMAR: Learnings from Advanced Agrilytics' Corn Trials

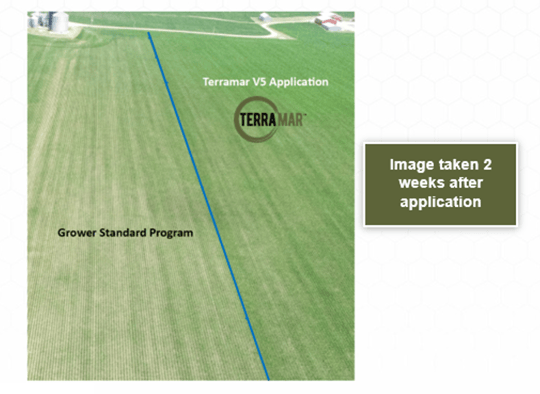

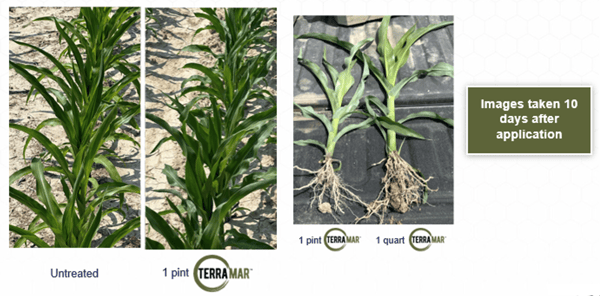

During the 2024 season, Advanced Agrilytics evaluated TERRAMAR on ten farms across Iowa, Illinois, Indiana and Ohio to look at nutrient uptake and crop performance metrics. On all farms, TERRAMAR was foliar-applied on V6 corn at a rate of 1 quart/acre and compared to the grower's standard practice alone (no TERRAMAR treatment).

What were some of the key findings?

- TERRAMAR increased nutrient levels in the treated corn plants. With a foliar application of TERRAMAR, crop uptake of both nitrogen and phosphorus was increased compared to the untreated plants. At R1, nitrogen was increased in over 50% of samples compared to the controls, while phosphorus was increased in nearly 80% of the samples. Higher levels of total plant nitrogen and phosphorus are indications of TERRAMAR’s ability to make nutrients more available to the plant and convert the starches, sugar and carbohydrates needed for yield.

- TERRAMAR increased sucrose concentration in the treated corn plants. Sucrose levels in the plant at R1 are the most reliable predictor of yield capacity. Sucrose in the stalk is essentially the fuel reserve that the plant has to draw from to fill kernels. A V6 application of TERRAMAR led to increased R1 sucrose levels in 75% of the samples compared to the controls. Further, when there was a PRE application of EXTRACT followed by TERRAMAR, sucrose was increased 100% of the time.

- TERRAMAR provided yield benefits in both water-limited and stable environments. The greatest yield advantage (69% positive outcomes) was seen in water-limited environments.

You can hear more about the trial findings by watching a recap of this webinar, during which AJ Woodyard, agronomy lead for Ag Ingenuity Partners (the independent research arm of Advanced Agrilytics), provides trial details.

A Note on Soybeans

In soybeans, there has been minimal plant growth in the last two to three weeks due to cooler conditions. TERRAMAR can be applied to soybeans to increase the uptake of a broad range of nutrients, including potassium, which is vital for starch and protein formation and can help regulate the stomata as temperatures increase in June. By applying TERRAMAR to their crop, soybean growers have the opportunity to boost plant development for quicker row closure and create more plant mass to support the upcoming reproductive stage.

Learn more about TERRAMAR by downloading the TERRAMAR booklet.

Jason Jaggers is a third-generation corn and soybean farmer in Wyanet, Illinois. When it comes to getting advice from his

Jason Jaggers is a third-generation corn and soybean farmer in Wyanet, Illinois. When it comes to getting advice from his

Many agricultural areas across the United States are facing weather-related challenges, but there are still opportunities to make the most

Many agricultural areas across the United States are facing weather-related challenges, but there are still opportunities to make the most

With fall fertilizer season approaching, Agricen’s Scott Lay spoke with WITY Radio about using

With fall fertilizer season approaching, Agricen’s Scott Lay spoke with WITY Radio about using