Growers who spread dry fertilizer on corn fields going to soybeans may want to consider the results of this Titan XC trial from Cozad, Nebraska. In a test plot, treating dry fertilizer with Titan XC provided a 14 bushel/acre yield advantage in soybeans compared to the soybean plots where untreated fertilizer was applied.

By accelerating the breakdown of treated dry fertilizers, Titan XC makes nutrients more available for plant uptake and utilization, which can benefit every crop. Learn more by watching a Titan XC webinar.Blog

As growers deal with tight budgets and carefully evaluate all of their input costs, a simple dry fertilizer demonstration shows why Titan XC is important to any operation's bottom line.

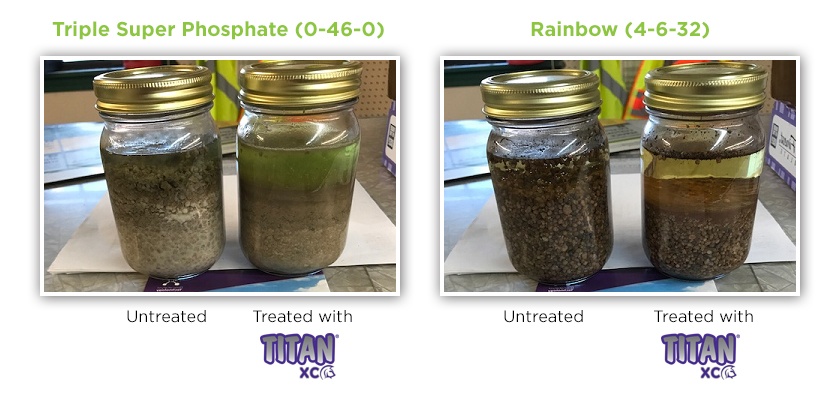

Prepared by Nutrien Ag Solutions in Cecilia, Kentucky, these jar tests shows the value that Titan XC brings when applied to dry fertilizers. As you can see in the photos, Titan XC has accelerated the breakdown of fertilizer prill in the treated jars, translating into greater nutrient release and improved fertilizer efficiency in the field. All photos were taken after three weeks.

You can see similar results in this time-lapse video of fertilizer breakdown with Titan XC on 9-23-30, 11-52-0 and MESZ fertilizers.

Download the Titan XC product booklet or contact Nutrien Ag Solutions to learn more about using this biocatalyst technology for dry fertilizers.

One of the main reasons growers use Titan XC is to speed the breakdown of dry fertilizer prills, which makes nutrients more quickly available for crop uptake. Loveland Products recently conducted a quick demonstration to quantify the rate of enhanced fertilizer breakdown with Titan XC. The results show that Titan XC does what it says.

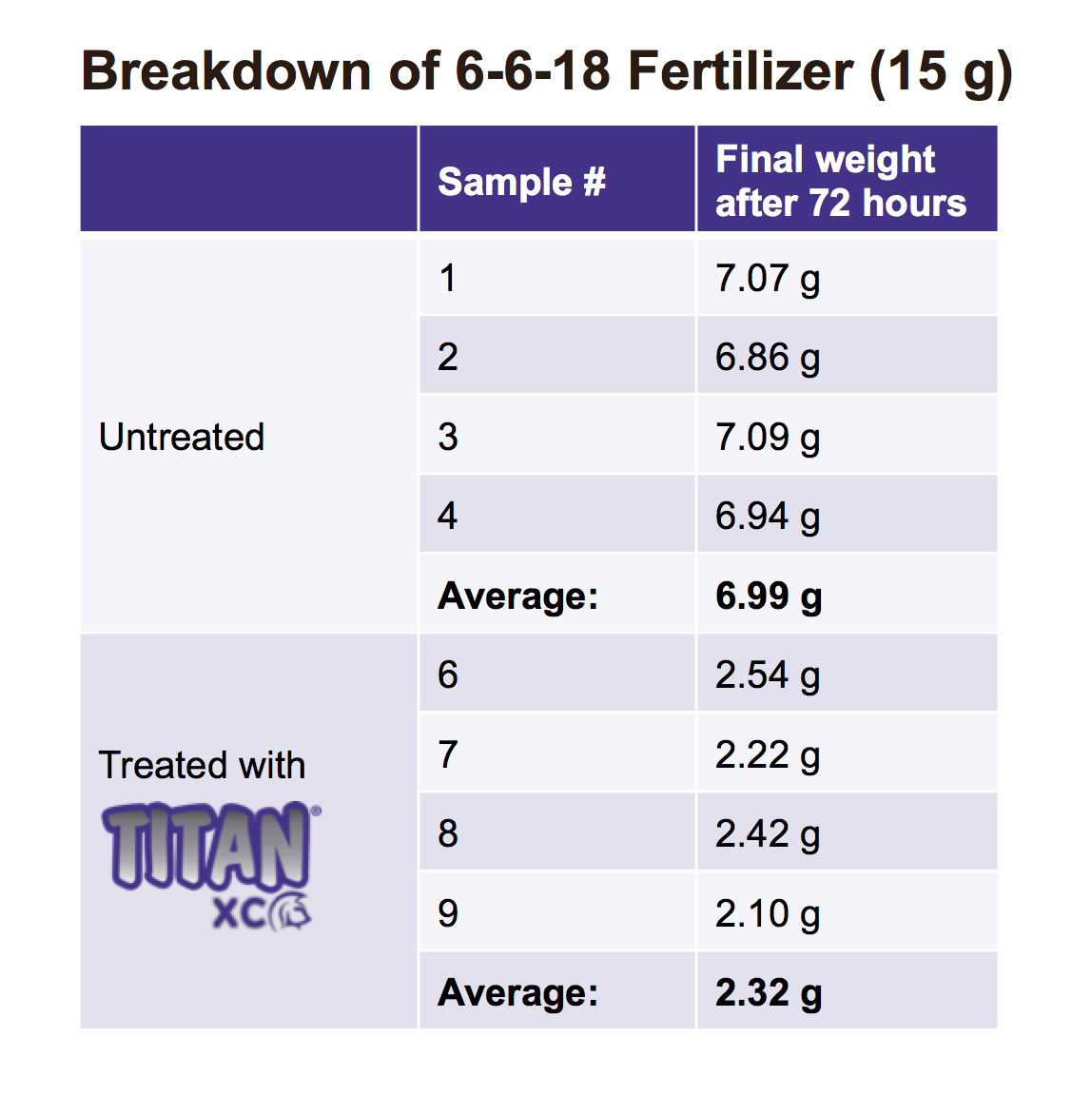

The demo compared Titan XC-treated versus untreated 6-6-18 fertilizer. The starting weight of each of the 8 samples tested in this demo (4 untreated and 4 treated) was 15 grams. All samples were submerged in distilled water for 72 hours, then screened off and weighed.

In every case, more Titan XC-treated fertilizer was dissolved compared to untreated fertilizer. Overall, Titan XC increased fertilizer breakdown by an average of 32%.

Untreated fertilizer prills (top row) vs prills treated with Titan XC (bottom row).

The average final weight of the Titan XC-treated samples was 2.32 grams, compared to 6.99 grams for the untreated samples.

In addition, analysis of the distilled water after the fertilizer was screened off showed a 25-83% increase in nutrient content (depending on the nutrient) in favor of Titan XC versus untreated fertilizer.

Although there are many different variables at play when it comes to prill breakdown (e.g., things such as application timing, rainfall/soil moisture, or incorporated vs. no-till practices), this quick demonstration shows that incorporating Titan XC into a dry fertilizer application speeds prill breakdown and rapidly releases nutrients for plant uptake.

---

See more results by accessing our featured study on fertilizer prill breakdown with Titan XC.

Titan XC is now available from Loveland Products! Designed to improve dry fertilizer efficiency, Titan XC is a new, next-generation biocatalyst for dry fertilizers that ‘unlocks’ applied nutrients, making them available more quickly so that more of them are taken up by plant roots. It is extra concentrated for easier application and superior impregnation onto fertilizer prill.

Titan XC is now available from Loveland Products! Designed to improve dry fertilizer efficiency, Titan XC is a new, next-generation biocatalyst for dry fertilizers that ‘unlocks’ applied nutrients, making them available more quickly so that more of them are taken up by plant roots. It is extra concentrated for easier application and superior impregnation onto fertilizer prill.

“For a grower’s dry fertilizer program, Titan XC is the key to quick release and uptake of a broad range of vital plant nutrients. This can really maximize the return on a grower’s dry fertilizer investment,” says John Oesch, Marketing Manager for the Southern Ohio division of Crop Production Services (CPS).

Titan XC offers growers benefits that include:

- Increased nutrient availability and uptake

- Enhanced nutrient use efficiency

- Better root growth and development

- Improved plant performance

- Optimized yield potential

The recommended rate for impregnation on dry fertilizers is 1 to 2 pints of Titan XC per ton of dry fertilizer.

Titan XC is manufactured for Loveland Products by Agricen.

---

Learn more about Titan XC by downloading the Titan XC product booklet.

By Fred E. Below, PhD, Professor of Plant Physiology, Department of Crop Sciences, University of Illinois at Urbana-Champaign

Agronomic advancements have brought corn yields to new heights, but producers have had little guidance on how to meet the nutrient requirements of modern, high-yield corn hybrids in a way that maximizes their yields. As a result, the high yields we see today have been accompanied in many places across the United States by a significant drop in soil nutrient levels, particularly phosphorus (P), potassium (K), sulfur (S) and zinc (Zn). This combination—higher yielding hybrids and decreasing soil fertility levels—suggests that producers have not sufficiently matched their maintenance fertilizer applications with nutrient uptake and removal by the corn.

By better understanding nutrient uptake and partitioning, producers can optimize their fertilization practices to meet their crop needs and attain maximum yield potential. I’ll focus here primarily on the uptake, partitioning, and utilization of P and K by corn.

Typical fertilization for corn in the United States is 180 lbs of N, 90 lbs of P2O5 and 160 lbs of K20 per acre, with no S or micronutrients. For modern corn hybrids in high-yielding systems, mineral nutrients with high requirements for production (i.e., nitrogen [N], P, K) or with a high harvest index (HI: the percentage of total plant uptake that is removed with the grain) (i.e., N, P, S, Zn) are important for obtaining high corn yield (Table 1).1

Producers must consider the impact of increased grain and stover nutrient removal on the next crop and employ appropriate fertilizer strategies to ensure that adequate nutrients are available to the crop. Phosphorus is probably one of the most overlooked nutrients, and most farmers are not putting out enough. In relation to total uptake, nearly 80% of P is removed in corn grain, while K is retained to a higher percentage in stover.

Production practices that utilize above-ground stover (i.e., cellulosic ethanol, silage production) may remove an additional 20.8 lbs of N, 4.0 lbs of P2O5, and 23.3 lbs of K2O per ton of dry matter, along with micronutrients. While farmers in Illinois, for example, fertilize 93 lbs P2O5 per acre, on average, for corn production2, the large majority (~80%) of soybean fields receive no applied P. As a result, they would have only the remaining 13 lbs/acre of P2O5 available for soybean production in a corn–soybean rotation3, where P and K fertilizer are commonly applied for both crops in the corn production year. This value would be inadequate to meet soybean P needs for total uptake (48 lbs/acre P2O5) or nutrient removal (30 lbs/acre P2O5) based on a conservative yield estimate of 46 bushels/acre in Illinois.4 Clearly, typical fertilization practices may need to be adjusted to meet crop nutrient needs.

Mineral nutrients are not all acquired at the same time or used in the same way by corn plants, and some require season-long uptake by corn roots for the crop to achieve a high yield. During the V10 to V14 growth stages, 230 bushel corn requires 7.8 lbs of N, 2.1 lbs of P2O5 and 5.4 lbs of K2O per day, but these needs change at other times. To optimize their programs, producers need fertilizer sources that supply nutrients at the rate and time that match their plants’ nutritional needs.

Potassium accumulates more than three-fourths of total uptake by VT/R1 (Figure 1)1, while over 50% of total P uptake occurs during grain fill (after VT/R1) (Figure 2)1, in addition to remobilization of 57% and 77% of the maximum measured leaf P and stalk P contents, respectively. This suggests that a season-long supply of P is critical for corn nutrition, while availability of K at levels that can meet the maximum rates of uptake during early season vegetative growth would be expected to meet corn nutritional needs, since the majority of K uptake occurs during vegetative growth. Thus, practices that are effective for one nutrient may not improve uptake of the other.

Nutrient management is complex, but improved fertilizer use can be achieved by understanding patterns of nutrient uptake, partitioning, and utilization. Producers should pay special attention to P requirements as productivity increases, as current data suggest a looming soil fertility crisis if adequate adjustments are not made in P usage rates. Agronomic advancements have brought corn yields to new heights, but understanding how to maintain soil nutrient levels can go a long way in helping to sustain high yields.

---

Learn how biocatalyst technologies can improve nutrient availability and uptake to help meet the nutrient needs of corn and other crops by downloading the Biocatalyst Technology FAQ Booklet.

References:

- Bender RR, Haegele JW, Ruffo ML, Below FE. 2013. Nutrient uptake, partitioning, and remobilization in modern, transgenic insect-protected maize hybrids. Agron. J. 105:161–170.

- National Agriculture Statistics Service (NASS), United States Department of Agriculture. Fertilizer and Chemical Usage. 2011. Illinois Farm Report. 32:8.

- NASS. Fertilizer, Chemical Usage, and Biotechnology Varieties. 2010. Bulletin As11091, Illinois Agricultural Statistics.

- Usherwood, N.R. 1998. Nutrient management for top-profit soybeans. News and views. Bulletin RN 98105. Potash and Phosphate Inst., Int. Plant Nutrition Inst., Norcross, GA.

As summer fades, many growers around the country are starting to think about how to best implement and manage their fall dry fertilizer programs. Before the spreaders take to the field, growers will need to answer a number of important questions, from “What type of fertilizer to choose?” to “Am I trying to maintain or build nutrient levels in the soil?”

The majority of growers who apply dry phosphorus (P) and potassium (K) fertilizers in the fall will also have two other major concerns:

- What amount of applied fertilizer will become or remain available to the crop in the following growing season?

- How can I get better first-year recovery out of my fall dry fertilizer application?

One way for growers to answer these questions and make management decisions is by understanding the efficiency of P and K fertilizers. In this blog, we will talk more about P and K fertilizer efficiency and about some ways to help growers get better first-year nutrient recovery.

Satisfying the Nutrient Demands of Hybrid Corn: Are We Doing Enough?

Even though the use of commercial inorganic fertilizers has risen dramatically in the past 50 years to try to meet the nutrient demands of hybrid corn, soil test information from the International Plant Nutrition Institute (IPNI) suggests that growers are not keeping up with P and K demands of new high-yielding corn varieties.

Today, a 200-bushel corn crop requires 256 units of nitrogen (N), 103 units of P, and 263 units of K (these units take into account NPK in corn residue).1 But as grain production increases, the demand for NPK also increases. In spring and summer seasons with ample moisture, corn yields can surpass the 200 bushel/acre mark by as much as 20-50 bushels/acre, leading to a drawdown of soil P and K levels because the fertilizer application was calculated and applied for the 200 bushel/acre yield.

To illustrate this phenomenon, Figure 1 below shows the changes in P and K levels in the Corn Belt from 2005-2010.2 All of the Corn Belt states experienced a reduction in soil P levels from 2005 compared to 2010, and most states declined in soil K levels as well.

Figure 1. Median soil P and K levels (50 percent of samples are above and below these levels) for the Corn Belt states and Ontario. The lower numbers in the maps are the changes from 2005. (Source: IPNI Corn Belt Fertility Study: 2010)

Another alarming issue is the inefficiency of our applied P and K fertilizers. Figure 2 below reveals the stark inefficiency of applied P fertilizers and the wide range of efficiencies for applied K fertilizers.

Figure 2. First-year nutrient efficiency/recovery. (Source: IPNI)

Many US growers make a dry application of P and K fertilizer in the spring or fall.

Unfortunately, because of the circumstances described above, many of these growers are not going to get the first-year P and K efficiency and recovery they need.

How can growers increase the availability of applied P and K to meet crop demands?

The Answer May Be in the Soil Chemistry and Biochemistry

To help answer that question, there are a few important points to remember about interactions that occur in the soil-plant system when dry fertilizers are applied:

- Essential crop nutrients are taken up into plant roots as positively charged cations or negatively charged anions (e.g., Ca+2, NO3-).

- The soil itself has a net negative charge and attracts or holds positively charged cations on cation exchange sites (cation exchange capacity, CEC).

- Negatively charged anions like nitrate have a high propensity to move below the plant root zone if excessive soil moisture is present.

- Chemical reactions (soil chemistry) also play an important role in the formation of compounds that are vital to plant growth.

- Strong attractions among cations, anions, and other compounds can prevent plants from accessing essential nutrients (e.g., when Ca+2 & Fe+2 bind to PO4).

When faced with these interactions, we must rely on the biochemical compounds produced by microorganisms to react with and release the bound nutrients, making them available for plant uptake and utilization.

Titan, a biochemical fertilizer catalyst, can be incorporated into a grower's existing dry fertilizer program to increase P and K availability and improve plant uptake. The concentrated biochemistry in Titan works in the soil profile to aid the mineralization of organic nitrogen and phosphorus into inorganic forms plants use. It also helps to improve soil issues to allow the release of bound potassium from the soil layers. This means that more of the applied fertilizer will become or remain available to the crop in the following growing season, helping growers answer a crucial management question. Figure 3 shows some examples of the results of using Titan with dry P and K blends.

Figure 3. Results with Titan impregnated on dry fertilizer.

Conclusions

The days may be getting shorter, but with some simple planning, it’s easy to get more nutrient recovery from any fall dry fertilizer application. The end result is increased crop yields and total economic return from your growing program.

References:

- Sutch R. (2011). The Impact of 1936 Corn Belt Drought on American Farmers’ Adoption of Hybrid Corn. In: Libecap GD and Steckel RH, eds. The Economics of Climate Change: Adaptations Past and Present (p. 195 - 223) Chicago, Illinois: University of Chicago Press.

- Mosaic Company's Nutrient Removal App. Available at: http://www.agprofessional.com/news/Mosaic-introduces-new-nutrient-removal-data-app-135169923.html.

- IPNI Corn Belt Fertility Study: 2010

![[Trial] Titan XC Provides 14 Bushel Yield Advantage in Soybeans](https://www.agricen.com/hubfs/TitanXC-soybeans.jpg)

![[Video] Fertilizer Breakdown with Titan XC](http://www.agricen.com/hubfs/prill.png)

![Faster Fertilizer Prill Breakdown with Titan XC [Demo]](http://www.agricen.com/hubfs/Titan_XC_increase_in_fertilizer_breakdown.png)