Achieving the proper balance of phosphorus and zinc in the soil is critical to early crop growth and development, setting the crop up for optimal yield potential later in the growing season. PROLOGUE is a unique biological product that enhances phosphorus and zinc nutrition in a variety of crops when used at planting in either an in-furrow or 2x2 banded application with any liquid fertilizer blend. PROLOGUE can help ensure that these nutrients are in the right balance for the crop.

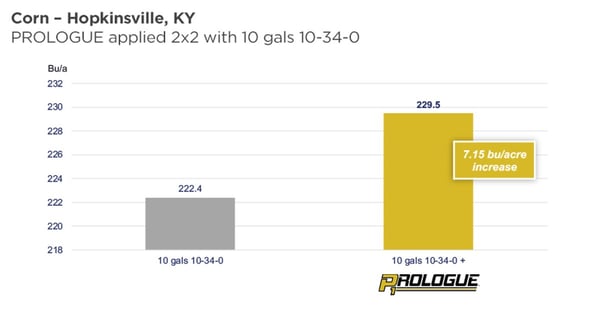

In 2024, the Nutrien Ag Solutions Innovation Farm in Hopkinsville, KY conducted a replicated strip trial to evaluate the benefit of adding PROLOGUE to UAN 32% in a 2x2 application at planting in corn, which requires a 10:1 ratio of phosphorus to zinc for optimal zinc availability.

The check treatment was 10 gallons per acre of UAN 32% banded 2x2 at planting, which was compared against the same rate of nitrogen with the addition of PROLOGUE at 2 quarts per acre, also applied 2x2. There were two replications per treatment. All other crop management practices were the same for both treatments.

Adding PROLOGUE to the UAN 32% fertilizer at planting led to a yield advantage of +14 bu/acre (6.3%) over the check, with an ROI of nearly 4:1. At harvest, the corn yield was 237 bu/acre with the PROLOGUE treatment, compared to 223 bu/acre with the check.

PROLOGUE contains two components that directly improve phosphate availability for corn root absorption:

- A biochemical component that increases phosphorus solubility and immediate availability of this essential nutrient early in the growing season. This component enhances the phosphate fertilizer PROLOGUE is applied with, as well as any phosphorus already residing in the soil of the application zone.

- A beneficial bacterium species in PROLOGUE colonizes the corn root rhizosphere upon seed germination, then continues to multiply and live in association with the root system for the majority of the growing season. During this time, the bacteria solubilizes more tightly bound forms of soil phosphorus in the rhizosphere and makes this soil phosphorus plant-available.

PROLOGUE also contains EDTA-chelated zinc, which both directly helps meet the plant's zinc nutrition needs and boosts the efficiency of applied and existing phosphorus.

PROLOGUE has an analysis of 5-0-0 6.3% Zn and can be applied in a range of crops, especially those that do best with an early season application of liquid phosphate near the developing root system.

Learn more about PROLOGUE by downloading the PROLOGUE booklet.

Many agricultural areas across the United States are facing weather-related challenges, but there are still opportunities to make the most

Many agricultural areas across the United States are facing weather-related challenges, but there are still opportunities to make the most