By Stephen Sexton (@AgricenLifer), Agricen

Yellow seedlings are a familiar sight for many corn growers. On continuous corn acres, the carbon-to-nitrogen ratio can be more than double the optimal ratio* for crop residue decomposition due to the buildup of organic matter from multiple years of corn-on-corn rotations. Even if a grower has applied nitrogen during the previous fall or around spring planting, soil microbes can out-compete seedling corn plants for nitrogen when excess carbon is present. The microbes use the nitrogen as a food source, immobilizing it as they work to degrade crop residues; the seedling corn plants, meanwhile, turn yellow due to a lack of available nitrogen.

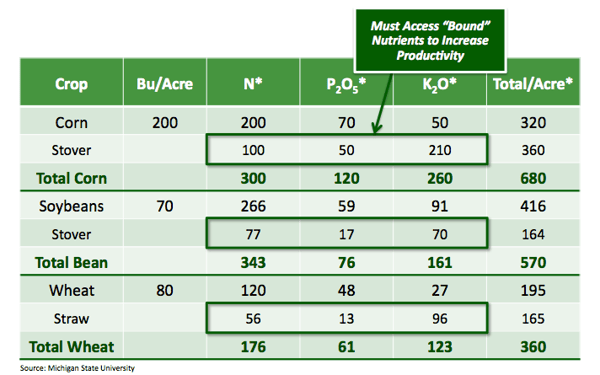

One effective way to solve the problem of yellow corn seedlings in corn-on-corn rotations is to lower soil C:N ratios by baling corn stalks for winter cow feed. Unfortunately, this is really only practical if one has cows—and most row crop farmers do not. In addition, complete removal of corn residue also takes away a significant amount of the N, P and K that comprises corn stover (Table 1).

Table 1. Nutrient Removal Chart for 200 Bushel Corn Residue

A second option for making sure seedling corn has enough nitrogen is obvious enough: apply more nitrogen to meet the needs of both the soil microbe system and the seedling corn. A common approach in the Corn Belt is to broadcast 10-15 gallons of UAN 28% on corn residue after harvest, with the idea that the extra nitrogen will facilitate rapid decomposition of the corn residue.

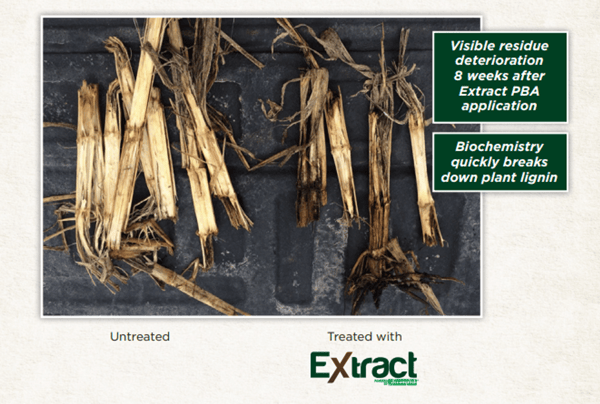

But more nitrogen isn’t necessarily the best or only solution for row crop growers. Numerous field trials show that ACCOMPLISH technology, which is found in the product EXTRACT PBA, can accelerate the breakdown of crop residues, even on no-till acres. The concentrated biochemistry in the product also effectively releases nutrients tied up in the stover—with resulting yield increases at harvest time.

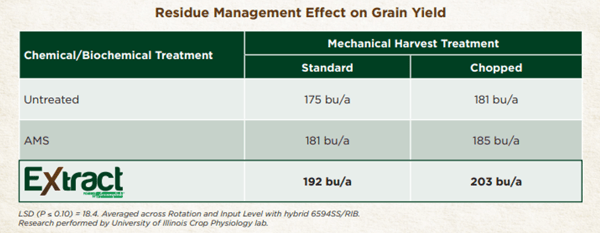

Research conducted at the University of Illinois illustrates the value of residue management using EXTRACT in a corn on corn system. In that trial (below), both mechanical chopping and the addition of ammonium thiosulfate (AMS), a nitrogen source, tended to increase yield through improved residue management, but only through the addition of EXTRACT did corn yield begin to exceed statistically significant levels.

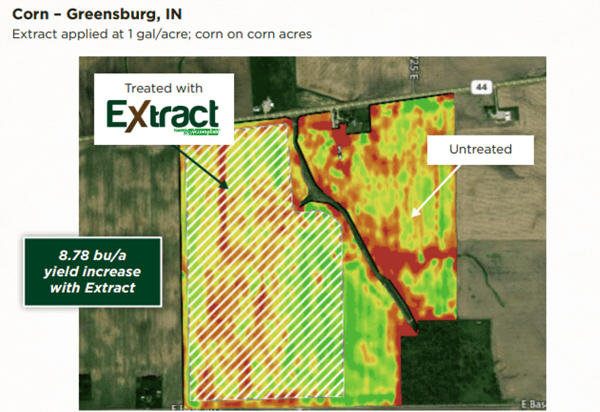

The practice of using EXTRACT to increase nutrient efficiencies in high-residue fields is supported by data from numerous trials, such as the corn trial from Indiana below, where a residue management application of EXTRACT in corn on corn acres resulted in a +8.78 bu/a yield increase at harvest compared to untreated acres.

Typically, residue applications with EXTRACT are made in October, when the ambient air and soil temperatures are cooling. The concentrated biochemistry in the product will continue to decompose corn residue even in cooler soil temperatures.

For any grower, it can be a challenge to optimize nutrient release from crop residue—and to get those nutrients mineralized in time for the growing season. But “more nitrogen” isn’t always the answer. Making EXTRACT part of your program is a cost-effective way to unlock the nutrients tied up in your stover, and keeps your seedling corn green.

*A C:N ratio of 20-30:1 is optimal.

Learn more about EXTRACT PBA by downloading the Maximizing Nutrient Release from Crop Residue booklet.