Why use a liquid starter fertilizer, and how can you make sure your applied nutrients don’t get tied up in the soil chemistry? Here you'll find the answers to these and other common questions about liquid starters.

Why use a liquid starter fertilizer, and how can you make sure your applied nutrients don’t get tied up in the soil chemistry? Here you'll find the answers to these and other common questions about liquid starters.

Why should I consider a liquid starter fertilizer?

Ensuring that seedlings have the nutrients they need for early growth is key to a good crop. The primary benefit of applying starter fertilizer is to enable more rapid growth early in the growing season. This can be viewed as an insurance policy, ensuring that plants reach critical growth periods faster.

By placing starter fertilizers in-furrow with the seed or in a 2x2 band near the seed, the plant has an accessible supply of phosphorus and other nutrients during germination and early development, which can increase growth early in the season, speed development and, for corn, decrease the time to silking.

Why is phosphorus important, and how do starter fertilizers impact the plant's access to phosphorus?

Phosphorus is a critical nutrient for early seedling vigor and root development, stimulating both root development and early shoot growth.

Application of low rates of phosphorus in a starter fertilizer can significantly increase the amount of early plant growth, even in fields where soil phosphorus test levels are high.

Further, in soils that are near or below 50°F, native soil microbes are not very active and are not producing the biochemistry that solubilizes soil phosphorus. Starter fertilizers can therefore provide needed phosphorus when planting in cooler soil temperatures.

Are most liquid starter fertilizers the same?

Not quite. There are two main types of phosphate found in starter fertilizers. They may be present as the sole form of phosphate in the fertilizer or found in combination with the other:

- Polyphosphates have a higher salt content and must be converted to orthophosphate before plants can utilize the phosphorous.

- Example: The phosphate in 10-34-0 liquid starter fertilizer is primarily polyphosphate, although some orthophosphate is present.

- Example: The phosphate in 10-34-0 liquid starter fertilizer is primarily polyphosphate, although some orthophosphate is present.

- Orthophosphates are low in salt and can be placed right on the seed. Although orthophosphates are readily available, they are easily tied up by soil chemistry.

- Examples: Liquid starter fertilizers like 7-17-3 and 9-18-9 contain only the orthophosphate form of phosphate. The majority of phosphate in 6-24-6 is in the orthophosphate form, although some polyphosphate is present.

Liquid starter fertilizers might also be formulated with different technologies or with micronutrients to enhance early season crop performance. Loveland Products' RISER (7-17-3 with Zn, Mn, Cu & Fe) is one example. In addition, fertilizer enhancement technologies can also be added to the program.

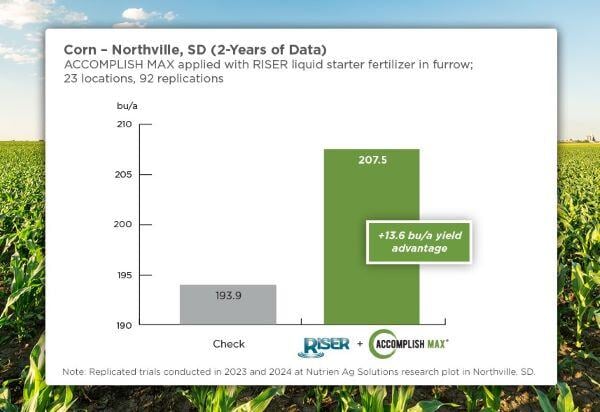

The trial data below shows one example of how pairing a starter with fertilizer enhancer technology can make a big impact. The average yield advantage gained by using a liquid starter fertilizer enhanced with ACCOMPLISH MAX technology was +13.6 bu/a compared to check (no starter). These results represent two years of Nutrien Ag Solutions trial data from research plots in northeast South Dakota, with 23 locations and a total of 92 replications.

How can I stop applied phosphorus from being tied up by the soil chemistry?

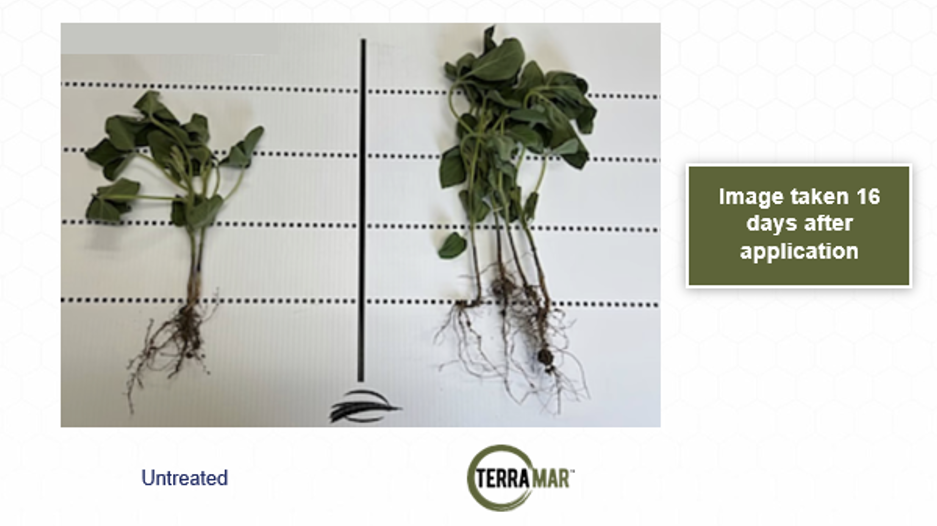

Whatever the liquid starter fertilizer you are using, adding a product like ACCOMPLISH MAX or PROLOGUE can make it go farther by enhancing nutrient mineralization—including mineralization of phosphorus—and facilitating nutrient uptake by the crop. (When applying dry starter fertilizers, TITAN XC can be used as an enhancement technology to improve nutrient mineralization and enhance nutrient availability to the growing crop.)

ACCOMPLISH MAX is specifically designed for use with liquid starter fertilizers in furrow or 2x2 to improve the mineralization of phosphorus and other nutrients while also improving the plant's tolerance to early season abiotic stresses like cool temperatures and salinity from applied fertilizers.

PROLOGUE (5-0-0 6.3% Zn) combines zinc, a critical early season micronutrient, with unique nutrient solubilizing technology that increases the efficiency of both applied phosphate and existing phosphate bound in the soil. It fits any banded liquid phosphorus-based fertilizer program requiring supplemental zinc for optimal plant growth.

These plant nutrition technologies can help your crops utilize more applied nutrients, which can lead to an increased yield while also improving the return on investment for your growing program.

Learn more about these products and other plant health technologies by accessing the Sustainable Plant Health Technology Overview.

Lee Lubbers, an

Lee Lubbers, an

Many agricultural areas across the United States are facing weather-related challenges, but there are still opportunities to make the most

Many agricultural areas across the United States are facing weather-related challenges, but there are still opportunities to make the most